-

Perfil de la empresa

Perfil de la empresa

Vista de fábrica

Cultura corporativa

Almacén

Organigrama

-

Investigación y desarrollo

Patentes tecnológicas

R&D Centro

Equipo

-

Relaciones con inversores

Política de ética empresarial

Relaciones con inversores

-

Ocupación

Promoción de empleados

Reclutamiento

Benfits

-

Primera base de fabricación de tubos de acero

Tubo de acero al carbono

Tubo de acero ERW

Tubo de acero LSAW

Tubo de acero Ssaw

Tubería de acero sin costura

Tubo de hierro dúctil

Varilla de refuerzo

Barra redonda de acero

-

Segunda base de fabricación de tubos de acero

Tubo de acero inoxidable

Tubo de acero sin costura de acero inoxidable

Tubo de acero soldado de acero inoxidable

-

Tercera base de fabricación de tubos de acero

Sección hueca

Manga de tarjeta cuadrada

Tubo rectangular

-

Base de fabricación octg

Productos ocgg

Manguito y manguito atascado

Tubería de perforación

Collares de perforación

Articulación pup

Manga ranurada

Carcasa de pantalla

-

Base de fabricación de accesorios

Accesorios de tubería

Borde de la rueda

Válvula

Codo

Reductores

Tres enlaces

-

Base de fabricación de tuberías metálicas

Tubo de metal

Tubo de cobre

Tubo de aluminio

-

Base de fabricación de productos procesados

Productos procesados

Tubería con brida

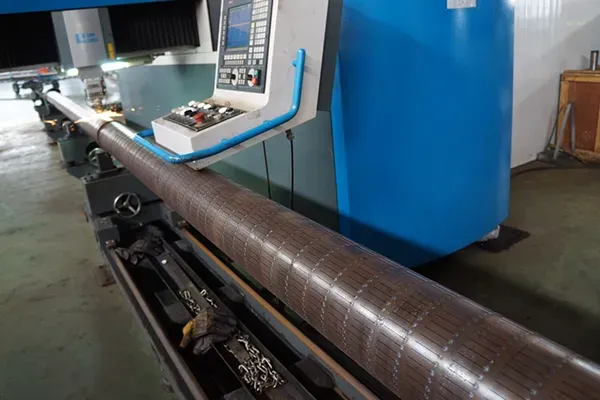

Tubería ranurada

-

Servicios

Hilo de tubería

Rampa de tubería

Recubrimiento de tuberías

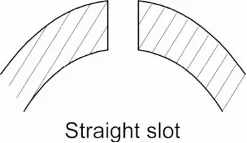

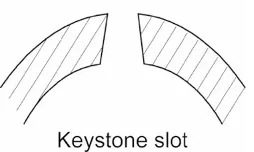

Ranura de corte rodado

Corte de tuberías de precisión

Shot shot

-

Proceso

Proceso de fabricación de acero

Proceso de fabricación de casquillos de tarjetas

Proceso de tratamiento térmico

Proceso de acabado de la carcasa de la tarjeta

Proceso de recubrimiento

-

Proyecto

Proyectos nacionales

Proyectos nacionales

Proyectos de financiación

-

Alcance de la operación

Fabricación de acero

Comercio Internacional

Servicios de arquitectura

-

Control de calidad

Inspección

Transporte por tuberías

English

English Español

Español بالعربية

بالعربية

Teléfono:

Teléfono: Whatsapp:

Whatsapp: Correo electrónico:

Correo electrónico: