-

لمحة عن الشركة

لمحة عن الشركة

عرض المصنع

ثقافة الشركات

مستودعات

الهيكل التنظيمي

-

البحث والتطوير

براءة اختراع تقنية

مركز البحث والتطوير

معدات

-

علاقات المستثمرين

سياسة أخلاقيات الأعمال التجارية

علاقات المستثمرين

-

المهنية

تعزيز الموظفين

تجنيد

بنفيتس

-

أول قاعدة تصنيع أنابيب الصلب

أنابيب الكربون الصلب

أنابيب المتفجرات من مخلفات الحرب

مستقيم لحام القوس المغمور أنابيب الصلب

SSAW أنابيب الصلب

سلس أنابيب الصلب

أنابيب الحديد المطاوع

حديد التسليح

قضيب فولاذي دائري

-

ثاني قاعدة تصنيع أنابيب الصلب

أنابيب الفولاذ المقاوم للصدأ

الفولاذ المقاوم للصدأ الأنابيب الملحومة

الفولاذ المقاوم للصدأ الأنابيب الملحومة

-

قاعدة تصنيع أنابيب الصلب الثالث

قسم جوفاء

مربع بطاقة غلاف

أنبوب مستطيل

-

Octg قاعدة تصنيع

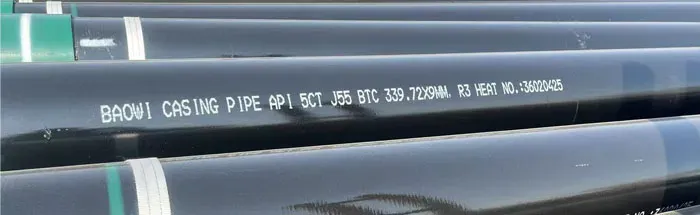

OCGG المنتجات

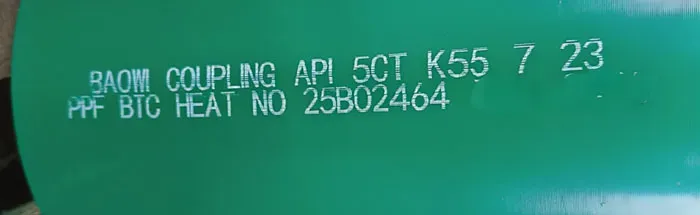

جلبة جلبة

أنبوب الحفر

طوق الحفر

pup المشترك

غلاف مشقوق

غربال شل

-

قاعدة تصنيع الملحقات

تركيب الأنابيب

ريم

صمام

كوع

مبطئ

ثلاثي

-

قاعدة تصنيع الأنابيب المعدنية

أنبوب معدني

-

الخدمات

أنابيب خيط سنّ اللولب

الأخدود الأنابيب

طلاء الأنابيب

قطع الأخدود

الدقة قطع الأنابيب

الرملي

-

عملية

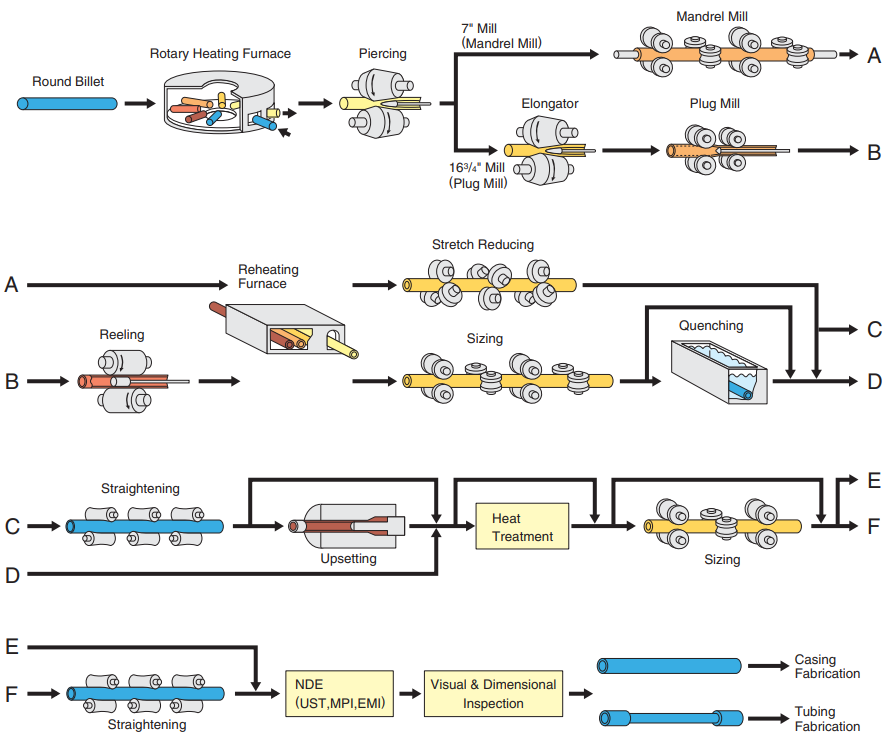

عملية صناعة الصلب

عملية تصنيع جلبة

عملية المعالجة الحرارية

الانتهاء من عملية لقط كم

عملية طلاء

-

المشاريع

المشاريع الوطنية

المشاريع المحلية

تمويل المشروع

-

نطاق الأعمال

صناعة الصلب

التجارة الدولية

الخدمات المعمارية

-

مراقبة الجودة

التفتيش

خط أنابيب النقل

English

English Español

Español بالعربية

بالعربية

تلفون .:

تلفون .: واتساب:

واتساب: البريد الإلكتروني:

البريد الإلكتروني: