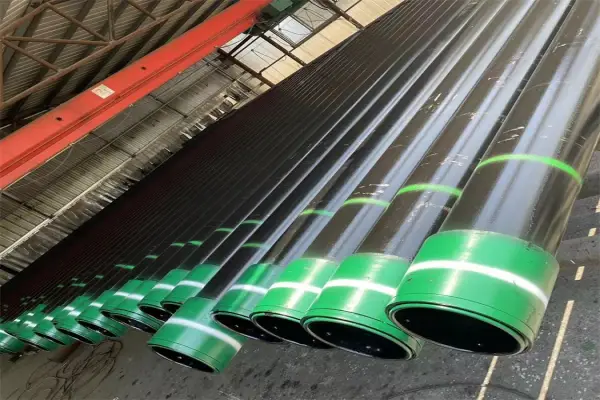

In oil and gas drilling, casing and tubing play a crucial role in maintaining wellbore integrity and ensuring the efficient extraction of hydrocarbons.

API 5CT is the standard specification for casing and tubing, setting requirements for chemical composition, mechanical properties, and manufacturing processes. Among the most commonly used grades are J55, K55,

N80, L80, and P110. This article will provide an in-depth analysis of these grades, explaining their properties, differences, and application scenarios.

1. Importance of API 5CT Casing and Tubing

Choosing the correct grade affects well safety and efficiency. Factors such as depth, pressure, and chemical conditions must be considered. Proper selection prevents failures and optimizes production.Casing and tubing are critical components in well construction. Casing is used to line the wellbore,providing structural support and preventing collapse, while tubing is the conduit for oil and gas production. API 5CT classifies these pipes into different grades based on their yield strength, chemical composition, and intended application.Each grade has specific mechanical properties designed to withstand varying downhole conditions, including pressure, temperature, and corrosion. The selection of the appropriate grade depends on the geological environment and the operational requirements of the well.

2. Description of API 5CT Grades

2.1 J55

Yield strength: 379 MPa (55,000 psi)

Tensile strength: 517-724 MPa (75,000-105,000 psi)

Applications: Low-pressure wells and drilling with minimal collapse risk.

This grade is used in shallow wells with low pressure. Its strength is suitable for conventional applications.API 5CT J55 and K55 casing and tubing are relatively low grade material pipe among all API 5CT pipes, they have same chemical composition and same yield strength 379-552 Mpa but in different tensile, J55 tensile strength minimum 517 Mpa which K55 is 655 Mpa. J55/K55 are lower grade than N80, L80, P110 or T95, so they are a cheaper option material and widely used in non corrosive oil well installation without high strength requirement.

2.2 K55

Yield strength: 379 MPa (55,000 psi)

Tensile strength: 655-724 MPa (95,000-105,000 psi)

Applications: Shallow wells with higher mechanical demands.

Similar to J55 but with slightly higher tensile strength. It is used when greater structural stability is required.

2.3 N80

Yield strength: 552 MPa (80,000 psi)

Tensile strength: 689-758 MPa (100,000-110,000 psi)

Applications: Medium-pressure wells with a higher risk of collapse.

This grade is used in medium-depth wells with more demanding conditions. Its strength is greater than J55 and K55.API 5CT Grade N80 type Q casing pipe is a medium grade in casing pipe products and has been widely used in oil and gas well drilling activities. Grade N80 has two level N80 type 1 and N80 type Q, more materials available like 9Cr-80 and 13Cr-80.

2.4 L80

Yield strength: 552 MPa (80,000 psi)

Tensile strength: 655-758 MPa (95,000-110,000 psi)

Applications: Wells with high corrosive gas content.

API 5CT L80 casing and tubing include grades L80-1, L80 9Cr (Cr 8%-10%), L80 13Cr (Cr 12%-14%), L80, minimum tensile strength 655 Mpa, yield strength 552 Mpa to 655 Mpa, it is a medium strength grade higher than J55/K55, and similar with N80 (YS 552 Mpa to 758 Mpa, TS 689 Mpa), L80 pipes has been used in oil well establishment, drilling and producinging oil and gas industries.

2.5 P110

Yield strength: 758 MPa (110,000 psi)

Tensile strength: 862-965 MPa (125,000-140,000 psi)

Applications: Deep drilling in extreme conditions.

The strongest of the common grades. It is used in deep wells with high pressure and extreme temperatures.API 5CT P110 Casing and Tubing is a high grade than J55/K55, N80, L80 and T95, tensile strength minimum 862 Mpa, yield strength 758 to 965 Mpa. P110 casing ends with white band to specify this material, it is widely used for oil drilling and producing in a particular surroudings especially for a deep oil well.

3. Comparison of API 5CT Grades

|

Grade

|

Yield Strength (MPa)

|

Tensile Strength (MPa)

|

Applications

|

|

J55

|

379

|

517-724

|

Shallow, low-pressure wells

|

|

K55

|

379

|

655-724

|

Greater stability in shallow wells

|

|

N80

|

552

|

689-758

|

Medium-pressure wells

|

|

L80

|

552

|

655-758

|

Sour gas wells

|

|

P110

|

758

|

862-965

|

Deep, high-pressure wells

|

4. Key Factors in Choosing the Right Grade

Selecting the correct API 5CT grade depends on multiple factors. Some of the most relevant include:

Well depth: Greater depth requires higher strength.

Internal and external pressure: An incorrect grade may cause structural failures.

Presence of corrosive gases: In harsh environments, L80 or special alloys are recommended.

Cost and availability: Advanced grades cost more but offer better safety.

5. Conclusion

Choosing the right API 5CT grade is crucial for well safety and productivity. J55 and K55 are suitable for low-pressure applications, while N80 and L80 offer greater strength and corrosion resistance. For deep drilling, P110 is the best option. Proper evaluation of operational conditions ensures efficient investment and optimal performance.For more information on API 5CT pipes, consult a specialized supplier. An informed decision enhances safety and extends the well's service life.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :