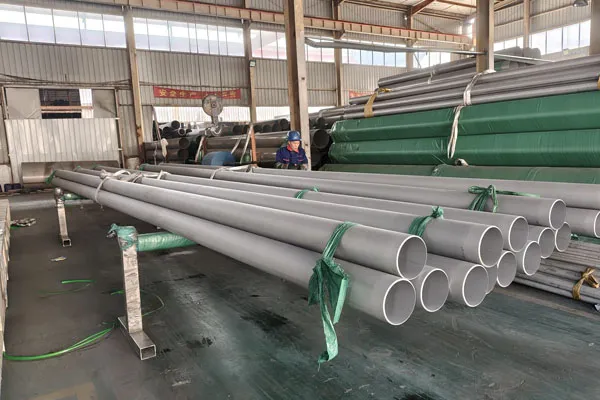

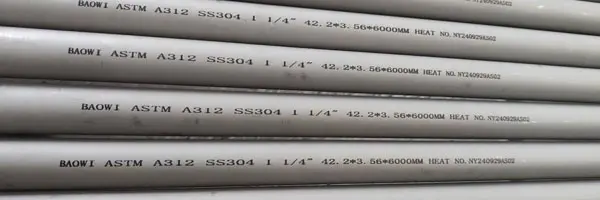

Stainless steel welded pipe is a pipe made of stainless steel plate or steel strip after curling and welding. Its production process is relatively simple, efficient, low cost, and has a variety of specifications. Although the strength of welded pipes is generally lower than that of seamless steel pipes, with the advancement of technology, the quality of stainless steel welded pipes has been continuously improved, and it has gradually replaced the application of

seamless steel pipes in many fields.

Two forms of stainless steel welded pipes

According to the form of weld seams, stainless steel welded pipes are mainly divided into two types: straight seam welded pipes and

spiral welded pipes.

The production process of straight seam welded pipes is simple, the production efficiency is high, and the cost is low, so it has developed rapidly. The weld seam of straight seam welded pipes is parallel to the longitudinal direction of the pipe, which is suitable for the production of small-diameter welded pipes.

Spiral welded pipes are usually stronger than straight seam welded pipes, and the raw materials used are more widely used. However, compared with straight seam welded pipes of the same length, spiral welded pipes have longer weld seams and relatively slower production speeds, so they are mostly used for large-diameter welded pipes.

Application Examples

Low-pressure fluid transportation

Galvanized welded stainless steel pipes for low-pressure fluid transportation are mainly used to transport low-pressure fluids such as water, gas, air, heating steam, and hot water. According to the wall thickness of the pipe, low-pressure fluid pipes can be divided into ordinary galvanized pipes and thickened galvanized pipes. In addition, the pipe end form can also be divided into threaded and non-threaded galvanized stainless steel pipes.

Electrical equipment protection

Ordinary carbon steel wire casings are mostly used in electrical installation projects in industrial and civil buildings as pipes to protect wires. Straight seam electric welded stainless steel pipes are often used in the production of electric welded steel pipes, electric welded thin-walled pipes, and transformer cooling oil pipes.

Pressure fluid transportation

Spiral seam submerged arc welded stainless steel pipes for pressure fluid transportation are formed by hot-rolled stainless steel strip coils and welded by double-sided submerged arc welding. This type of stainless steel pipe has a strong pressure bearing capacity, excellent welding performance, and is safe and reliable. Its larger diameter gives it an efficient transportation capacity and can save a lot of pipeline laying costs.

Spiral welded pipe for piles

Spiral welded stainless steel pipe for piles is mainly used in infrastructure such as docks or bridges. It uses hot-rolled stainless steel strip coils as pipe blanks, and after spiral forming, it is processed and formed using double-sided submerged arc welding or high-frequency welding technology.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :