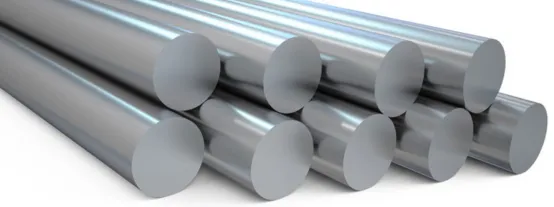

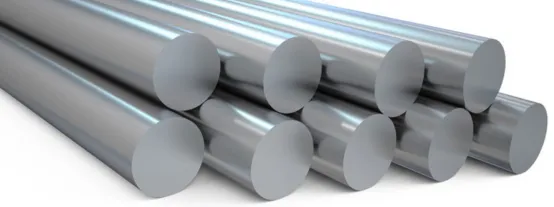

Types of round steel include low-alloy structural steel bars, alloy structural steel, free-cutting non-heat-treated steel, and stainless steel round bars. Based on surface treatment, they can also be classified into bright bars and black bars. Each type of round steel is selected based on its strength, toughness, corrosion resistance, and application requirements.

1.Low-alloy structural steel

refers to a type of alloy steel with an alloy element content of less than 3%, encompassing many standard and proprietary grades designed to provide specific combinations of desired properties, such as toughness, strength, formability, weldability, and atmospheric corrosion resistance.

Product Specifications

|

Standard

|

JIS / ASTM / AISI / SAE / EN /DIN / BS / GB / API

|

|

Grade

|

SS400, S355JR, S355J0, S355J2, Q345A-Q345E, Q460C etc.

|

|

Delivery Condition

|

U / N / A / S / FP / AC / QT / EFS

|

|

Shapes

|

Round / Square / Flat / Hexagon

|

Characteristics of Low-Alloy Structural Steel:

Higher Strength: Due to its significantly higher strength compared to equivalent carbon steel, low-alloy structural steel is also known as low-alloy high-strength steel.

Enhanced Mechanical Properties: Low-alloy structural steel is known for its better mechanical properties and resistance to atmospheric corrosion, making it a suitable substitute for conventional carbon steel.

Good Cutting and Welding Performance: Low-alloy structural steel can withstand the stresses of alternating fatigue loads and resist the processing steps involved in manufacturing.

2.Alloy structural steel

Alloy structural steel is a type of steel formed by adding different proportions of alloying elements such as manganese, chromium, nickel, molybdenum, and vanadium. The purpose of this is to improve the mechanical and physical properties of ordinary carbon steel, such as hardenability, tensile strength, yield ratio, fatigue strength, ductility, and corrosion resistance, making these types of steel suitable for manufacturing various mechanical parts with larger cross-sectional dimensions.

Product Specifications

|

Standard

|

JIS / ASTM / AISI / SAE / EN /DIN / BS / GB / API

|

|

Grades

|

41Cr4, 20Cr, 40Cr

|

|

SCr420, SCr440, SCM420, SCM440

|

|

709M40, 817M40, 826M40, 655M13

|

|

SAE4140, SAE 8620, SAE 8637, SAE 8640, SAE4340

|

|

TL4227, ZF6, ZF7, ZF7B, 1E1201, 1E0621, 1E1287, 1E1998

|

|

20CrMnTi, 18CrMo4, 25CrMo4, 42CrMo4, 42CrMoS4, 16MnCr5,

|

|

16MnCrS5, 20MnCrS5,17CrNiMo6, 8NiCrMo5, 39NiCrMo3,18CrNiMo76,

|

|

20MnCr5, 30CrNiMo8, 31CrMoV9, 34CrNiMo6, 38CrMoAl, 19CrNi4 etc.

|

|

Shapes

|

Round / Square / Flat / Hexagon

|

Characteristics of alloy structural steel:

Varying yield strength, tensile strength, tempering resistance, and plasticity.

Excellent physical or mechanical properties are obtained after specific heat treatment.

Widely used in the manufacture of various machine parts in ships, vehicles, aircraft, missiles, weapons, railways, bridges, pressure vessels, machine tools, etc.

3.Free-machining steel round bar

Free-machining steel is a type of steel alloyed with elements such as sulfur, lead, bismuth, phosphorus, selenium, and tellurium. The addition of these elements ensures that chips break off easily during machining, thus reducing machining forces, extending tool life, and improving the surface finish of the machined parts. This makes it ideal for applications where machining speed and surface finish are primary requirements.

Product Specifications

|

Standard

|

JIS / ASTM / AISI / SAE / EN /DIN / BS / GB / API

|

|

Grade

|

11SMnPb30, SAE12L14, C70S6, 19MnVS6, 30MnVS6, 38MnVS6, 46MnVS6, 46MnVS3, 49MnVS3, TL1438 etc.

|

|

Delivery Condition

|

U / N / A / S / FP / AC / QT / EFS

|

|

Shapes

|

Round / Square / Flat / Hexagon

|

Characteristics of easily machinable non-heat-treatable steel:

Excellent machinability, such as improved machining speed and surface finish of machined parts.

Longer tool life: Service life and production efficiency can be increased by 40%.

Better plating performance and a cost-effective alternative to copper products.

4.Stainless Steel Round Bar

Stainless steel round bar is a solid bar made of stainless steel, possessing excellent corrosion resistance, strength, and durability. It is widely used in mechanical manufacturing and industrial applications.

Product Specifications

|

Grade

|

1. Austenitic Stainless Steel: 304, 316, N08028, Nitronic 50…

|

|

2. Ferritic Stainless Steel: 9Cr1Mo/T91/F91, 409, 430…

|

|

3. Martensitic Stainless Steel: 410, 420M, Super 13Cr, 440C…

|

|

4. Duplex Stainless Steel: S31500, S31803, S32205, S32304, S32750, S32760…

|

|

5. Precipitation-hardening Stainless Steel: 13-8Mo, 15-5PH, 17-4PH…

|

|

Delivery Condition

|

Hot Rolled, Annealed, Pickled, Cold draw, Sandblast

|

|

Specification

|

ASTM A276/A276M/A484/484M

|

|

Size

|

Hot Rolled: 10-120mm

|

|

Cold Drawn: 3-60mm

|

|

Forged: 120-500mm

|

Characteristics of Stainless Steel Round Bars:

They feature tight tolerances with precise dimensions.

They are made of high-strength material with excellent corrosion resistance.

Due to their smooth surface, they are also an excellent material for decorations, monuments, and sculptures.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :