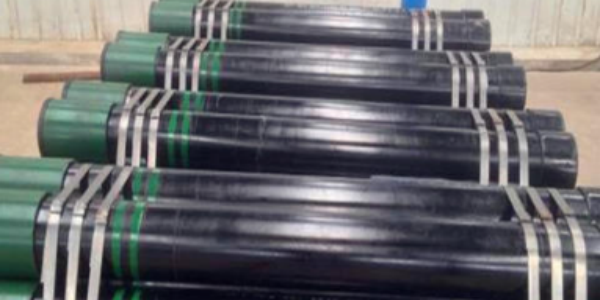

Pup joints and casings are common pipe fitting materials in petroleum engineering, which are related to the completion quality and production efficiency of oil wells. Oil Pup Joint is one of the key components used in the oil and gas equipment process. It connects the equipment and pipeline , and serves as a connection and seal to ensure the safety and smooth progress of the entire process. The processing technology of oil pup joints has a greater impact on the quality and performance of the product. There are many things that need to be paid attention to. This article will introduce some precautions for connecting oil casing of pup joints and how to maintain pup joints.

Pup Joints in the connection of oil casing precautions

First and foremost, inspecting the quality of the pup joint is critically important. Ensuring that the pup joint complies with API specifications and passes quality inspections is key to preventing accidents.

Secondly, when installing an API oil casing pup joint, attention must be paid to the tightness of the connection to avoid oil leaks or pressure loss. Using appropriate tools and techniques ensures a secure connection.

Additionally, regular inspection and maintenance during the use of oil casing pup joints are indispensable. Checking the surface of the pup joint for corrosion, deformation, or other issues and promptly addressing them through repairs or replacements can extend the service life of the pup joint and improve operational efficiency.

Finally, when using API oil casing pup joints, operational procedures must be followed. Operators should receive professional training, understand the principles and methods of using pup joints, and achieve proficiency. During use, safety precautions must be observed to avoid accidents.

Beyond the points mentioned above, there are other aspects worth noting.

1. Processing accuracy

Pup joint is one of the key components of oil and gas drilling equipment, and its processing accuracy is related to drilling safety and drilling efficiency. Therefore, standards must be strictly followed during processing to ensure that product quality meets specified requirements.

2. Material selection

The material selection for Pup joint is generally high-strength alloy steel, and its strength, corrosion resistance, etc. need to be taken into consideration. At the same time, the weldability and plasticity of the product must also be taken into consideration to ensure that the product can meet engineering needs.

3. Inspection before installation

Pup joint need to be accepted and inspected before they are installed on drilling pipes and casing. Check its appearance quality, dimensional error, thread processing, etc. to ensure that the product does not have any quality problems.

4. Prevent damage

During the connection process, avoid using excessive force or tools to avoid damaging the connecting parts or threads. Avoid impact or collision on connecting parts and keep the connecting surface flat and intact.

5. Strictly follow the procedures

When connecting the pup joint and the oil pipe casing, the procedures and operating procedures should be strictly followed, and steps should not be changed or omitted without authorization.

How to maintain the pup joint?

If the pup joint is well maintained and maintained, it will not only extend the service life of the pup joint, but also better protect the normal operation of the casing and tubing. The following will introduce in detail some maintenance measures for the pup joint.

Regular cleaning: During the use of the oil pup joint, oil, dirt and other impurities inside and outside the pup joint should be cleaned regularly to keep it clean. Use appropriate cleaning agents and tools to ensure thorough cleaning to prevent impurities from causing damage to the short circuit.

Anti-rust treatment: For metal pup joint, anti-rust treatment should be carried out regularly, using anti-rust oil or anti-rust coating to protect its surface from oxidation and corrosion. Be careful not to expose the short circuit to moisture or corrosive media for a long time.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :