Pemex Oil Well Project, Mexico's State-Owned Oil Company

In 2022, Pemex, Mexico's state-owned oil company, launched an important oil well casing project. Our company was fortunate to receive a large oil casing demand order from Pemex's end customer. The total amount of this order exceeds 2,000 tons, which indicates that our capabilities and reputation in the oil and gas industry have been highly recognized.

Project Background

As the largest oil company in Mexico, Pemex (Petróleos Mexicanos) shoulders the heavy responsibility of national energy supply. This order is part of its new oil well project, which aims to increase domestic oil production, reduce dependence on imported energy, and ensure national energy security.

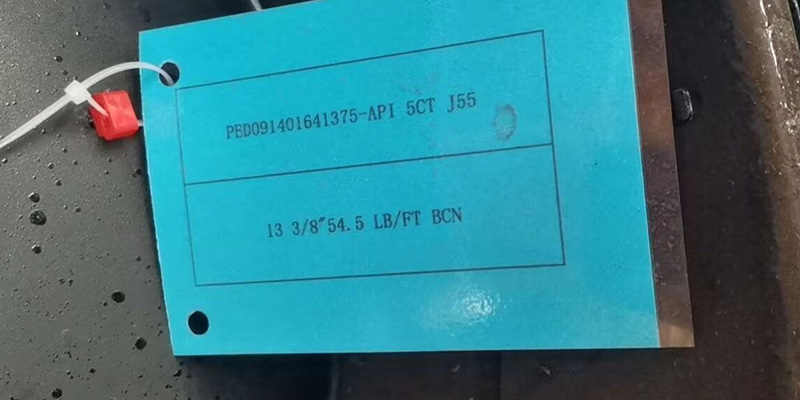

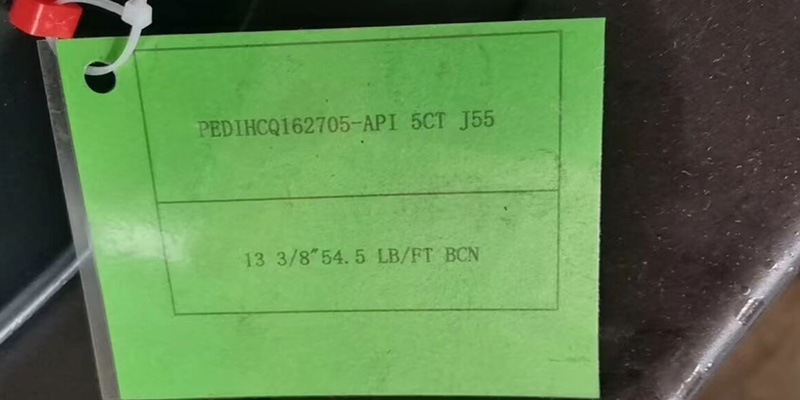

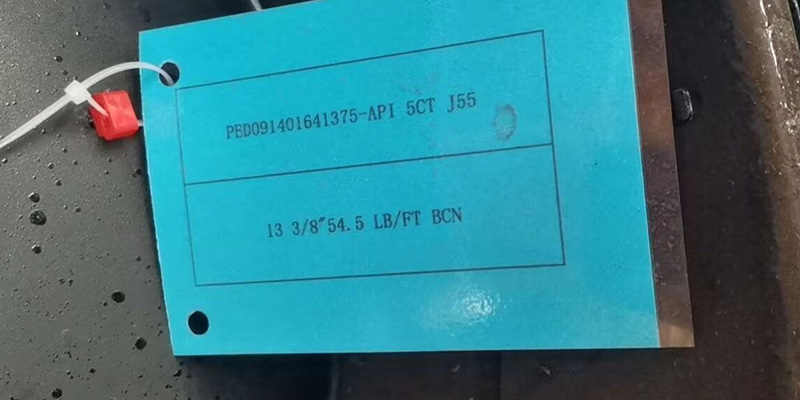

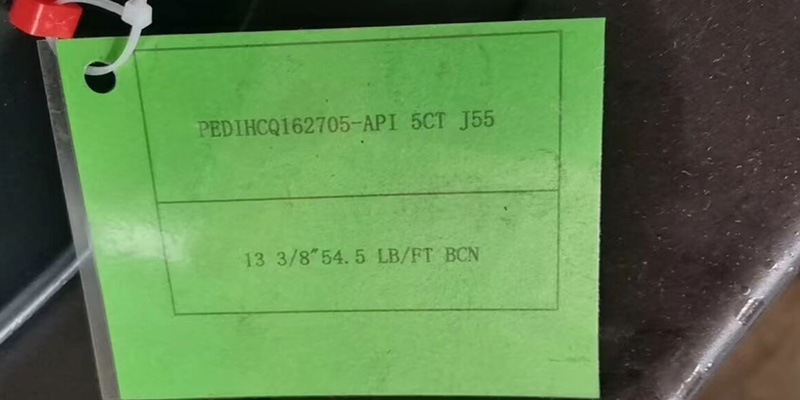

Order Details

All oil casings in this order adopt API 5CT standard. This standard was developed by the American Petroleum Institute (API) and is specifically used for casing and tubing in oil and gas wells to ensure safe and reliable operation in harsh underground environments.

Features of API 5CT Oil Casing

High Strength: API 5CT standard casing has high strength and can withstand the harsh conditions of high pressure and high temperature underground.

Corrosion resistance: These casings are specially treated to have good corrosion resistance and adapt to corrosive environments under different geological conditions.

Standardization: API 5CT casings are produced strictly in accordance with international standards to ensure product consistency and interchangeability.

Multiple steel grades: API 5CT standard covers a variety of steel grades (such as J55, K55, N80, L80, P110, etc.), which can meet the needs of different well depths and pressure environments.

Production and delivery

1. Production preparation

After receiving the order, we immediately started production preparation. The first is the procurement and quality inspection of raw materials to ensure that all materials meet the strict requirements of API 5CT standards. Subsequently, we adjusted the production line to ensure that every link in the production process meets high quality standards.

2. Production process

The production process includes multiple processes, from steel pipe manufacturing, heat treatment, to finishing and testing, every link is strictly controlled. We use the most advanced production equipment and testing instruments to ensure that each casing meets the expected quality standards.

Steel pipe manufacturing: The strength and sealing of the steel pipe are ensured through high-frequency welding and seamless steel pipe production processes.

Heat treatment: Through heat treatment processes such as normalizing and tempering, the mechanical properties and fatigue resistance of steel pipes are improved.

Finishing: The steel pipes are threaded, polished and anti-corrosion treated to ensure their durability in harsh environments.

Testing: Non-destructive testing methods such as ultrasonic testing and X-ray testing are used to ensure that each casing is defect-free.

3. Quality control

During the production process, we strictly follow the API 5CT standard and internal quality control process. Each batch of casing must undergo strict testing and inspection before leaving the factory, including dimensional inspection, mechanical property testing, compression and tensile testing, etc., to ensure that all products meet quality requirements.

4. Logistics and delivery

After production is completed, we arranged an efficient logistics and transportation plan to ensure that the casing is delivered safely and on time to Pemex end customers. Due to the large order volume, we delivered it in batches and completed all delivery tasks in the second half of 2022.

Project significance

The successful completion of this order marks our company's leading position in the production of high-quality oil casing, and also demonstrates our strong production and delivery capabilities. This not only strengthens our partnership with Pemex, but also lays a solid foundation for developing more business in Mexico and other regions in the future.

Through this cooperation, we have further understood customer needs and industry standards, and provided valuable experience for future development. At the same time, our products have performed well in practical applications, which has been highly praised by Pemex and enhanced our competitiveness in the international market.

Conclusion

In 2022, facing the huge demand of more than 2,000 tons of oil casing proposed by Pemex, we successfully completed the production and delivery tasks. This not only reflects the technical strength and production capacity of our company, but also shows our high attention to quality and customer needs. In the future, we will continue to uphold high quality standards, meet the needs of more customers, and contribute to the development of the global energy industry.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :