API 5B Line Pipe

In today’s global energy and infrastructure sectors, the demand for precision-engineered, reliable line pipe solutions has never been greater. As a leading API 5B Line Pipe Supplier, BAOWI Steel is proud to deliver high-performance line pipes that meet the strictest industry standards and support critical oil, gas, and fluid transport projects around the world.

"Processing, Measurement and Inspection of Casing, Tubing and Line Pipe Threads (API Spec 5B)" is one of the main standards for processing, measurement and inspection of casing and tubing threads at home and abroad. Since the release of the 16th edition of the standard (API Spec 5B 16th) in 2017, it has been widely used in oil pipe manufacturers, measuring tool manufacturers, oil field users, and testing and calibration institutions, effectively standardizing the processing and inspection of product threads and promoting the steady improvement of product thread quality. At present, the 17th edition of the standard (API Spec 5B 17th) is being widely solicited from the public.

The API 5B standard outlines the requirements for thread types (such as LTC, STC, BTC, and premium threads), and defines gauging practices and tolerances for both internal and external threads on steel pipes used in oilfield services. It works alongside API 5L (Line Pipe standard) and API 5CT (

Casing and Tubing) to ensure thread compatibility, sealing reliability, and field durability.

What Is API 5B and Why Does It Matter?

In practical terms, API 5B ensures that line pipes threaded at the ends will fit perfectly and perform as expected in demanding environments. Whether transporting crude oil, natural gas, or injecting steam in enhanced oil recovery (EOR), poor thread quality can lead to catastrophic failures—making API 5B compliance non-negotiable.

Differences between API 5B and API 5D

Pipes manufactured under different API specifications excel particularly in the petroleum industry. Specifications such as API 5B, API 5D, API 5L, and API 5CT are widely used in these industries. Pipes produced under API 5D are used for drilling and production, whereas API 5B covers different aspects such as thread processing, measurement, and inspection of threads of tubing, casing, and line pipe. Hence, it is easy to differentiate between API 5D and API 5B pipes.

Inspection procedures under API 5B are used to calculate parameters such as lead, taper, height, and moreover thread angles are only relevant for threads with TPI or turns per inch of about 11½ or less. All thread sizes (without tolerances) for API 5B casing and tubing are related to the joint design basis. Hence, they are not used for measurement to determine the acceptance or rejection of the product i.e. API 5B line pipe.

API specification 5D covers the designation of Group 1 and Group 3 drill pipe. While Group 1 considers Grade E drill pipe, Group 3 under API 5D

drill pipe covers all high-strength grades of drill pipe. These include Grade X-95, Grade G-105, and Grade S-135.

Common Thread Types Under API 5B

API 5B standardizes several types of threads, including:

External Upset Tubing (EUT) threads

Non-Upset Tubing (NUT) threads

Line Pipe (LP) threads

Short Round Thread (STC)

Long Round Thread (LTC)

Buttress Thread (BTC)

Each thread profile has specific performance characteristics in terms of pressure handling, ease of makeup, and resistance to fatigue—making the selection of the correct API 5B thread type essential for each project.

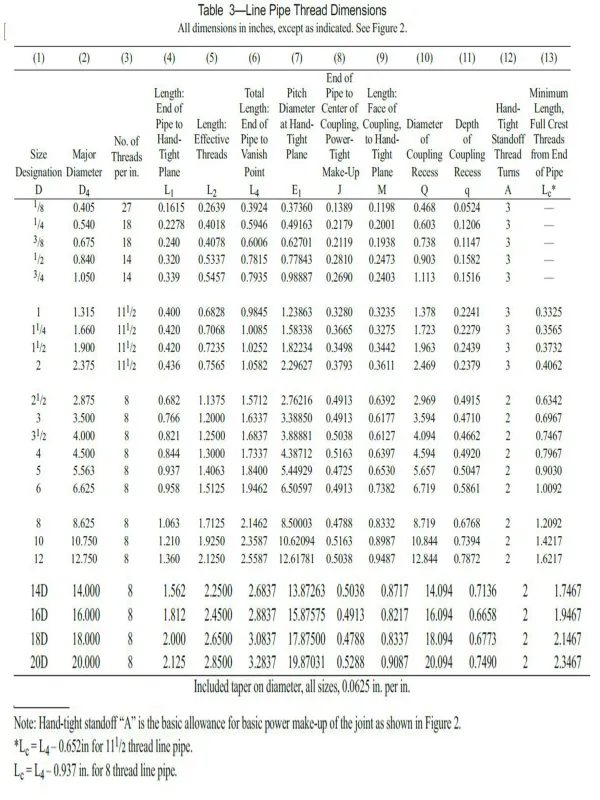

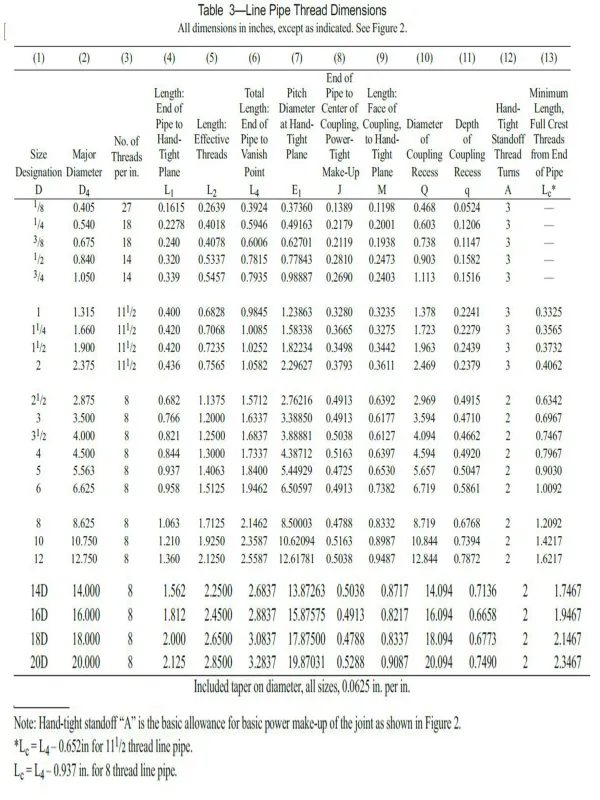

API 5B line Pipe thread Dimension

In today’s fast-evolving energy sector, API 5B isn’t just a technical specification—it’s a global language of reliability. For project managers, procurement officers, and engineers alike, understanding and specifying API 5B-compliant threaded line pipe can make the difference between a project that flows smoothly and one that fails under stress.

Need API 5B threaded line pipe or custom-threaded connections?

Contact our technical team for detailed dimension charts, samples, or a competitive quote.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :