Stainless steel butt-weld reducers, also known as stainless steel reducers, are a special type of stainless steel pipe fittings, mainly used to connect two pipes of different diameters. According to different structures, they can be divided into stainless steel concentric reducers and stainless steel eccentric reducers. Stainless steel concentric reducers refer to reducers where the centers of the two diameters are on the same center, which is suitable for controlling the flow rate of fluids and suitable for laying pipelines against walls or on the ground without taking up space. Stainless steel eccentric reducers refer to reducers where the centers of the diameters are not on the same center, and can be divided into two types: top flat and bottom flat. Top flat eccentric reducers are used to prevent gases with lower density from gathering upward and flowing out of the pipeline, while bottom flat eccentric stainless steel reducers are used to prevent fluids with impurities or accumulated liquid from sinking and blocking the pipeline.

Stainless steel reducers are widely used in piping systems. Today we will take a detailed look at its characteristics.

According to the size of the diameter of the stainless steel reducer, it is divided into one-time pressing or multiple pressing. The reducer shrinking forming process is to put the tube blank with the same diameter as the large end of the reducer into the forming mold, press along the axial direction of the tube blank, so that the metal moves along the mold cavity and shrinks. According to GB/T13401-2005, the roundness of the stainless steel reducer should not be greater than 1% of the outer diameter of the corresponding end, and the allowable deviation is ±3mm;

Distribution characteristics of stainless steel reducers:

1. Under the action of internal pressure, the bending moment generated by the pressure difference between the large and small ends of the concentric reducer causes the large end to open relatively and the small end to shrink relatively.

2. Under the action of internal pressure, the circumferential stress of the inner surface of the large end of the eccentric side and the outer surface of the middle part of the eccentric side of the eccentric reducer is large.

Manufacturing process of stainless steel reducers

Stainless steel welded reducers are mainly made by rolling steel plates or tumbling steel pipes. The appropriate manufacturing process is selected according to the pipe diameter.

Steel pipe tumbling method: For reducers with smaller pipe diameters, the steel pipe tumbling method is generally used. During the tumbling process, the steel pipe needs to be heated to 800-950℃ and hammered evenly during the heating process to gradually deform it to the required size. In particular, the lower wall of eccentric reducers is usually not heated to ensure accurate shape.

Steel plate rolling method: For reducers with larger pipe diameters, they are made by rolling, cutting and welding steel plates. During the rolling process, the steel plate needs to be cut into appropriate sizes, and then rolled, welded and shaped. Ensure that the rolling is uniform to avoid cracks or deformation.

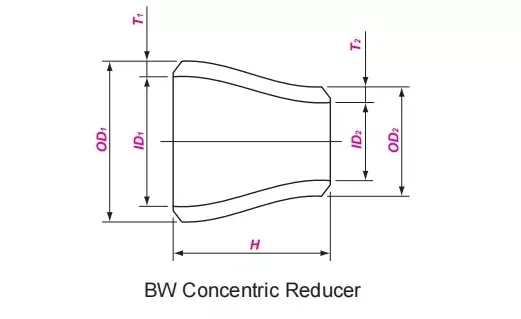

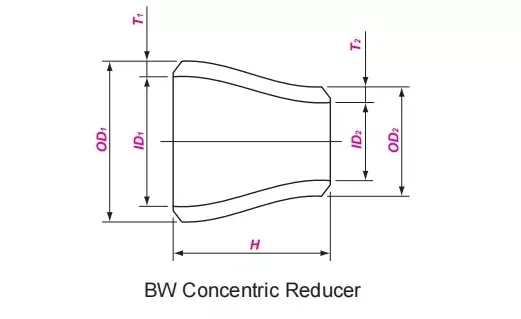

Dimensional characteristics of stainless steel concentricreducers

Stainless steel concentric reducers are butt-welded pipe fittings, produced in accordance with the American standard ASME B16.9. Their dimensional characteristics are reflected in their wide range of specifications, diverse wall thicknesses, wide application areas, and high degree of customization. These characteristics make them an indispensable and important component in the pipeline system.

|

Size Range

|

3/4" - 60" / DN20 - 1500

|

|

Thickness Schedule

|

SCH 10 - SCH 80, SCH 160, XXS

|

|

America Standard

|

ANSI / ASME B16.9 / MSS SP 43

|

|

Stainless Steel

|

ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L

|

ASME B16.9 concentric reducer size table

|

OD1

|

OD2

|

END TO END

|

|

NPS

|

NPS

|

H

|

|

3/4

|

3/8 - 1/2

|

38

|

|

1

|

1/2 - 3/4

|

51

|

|

1-1/4

|

2001/2/1

|

51

|

|

1-1/2

|

1/2 - 1-1/4

|

64

|

|

2

|

3/4 - 1-1/2

|

76

|

|

2-2/1

|

1/2

|

89

|

|

3

|

1-1/4 - 2-1/2

|

102

|

|

4

|

2 - 3-1/2

|

102

|

|

5

|

2/4

|

127

|

|

6

|

2-1/2 - 5

|

140

|

|

8

|

3-1/2 - 6

|

152

|

|

10

|

4/8

|

178

|

|

12

|

5/10

|

203

|

|

14

|

6/12

|

330

|

|

16

|

6/14

|

356

|

|

18

|

8/16

|

381

|

|

20

|

10/18

|

508

|

|

22

|

12/20

|

508

|

|

24

|

12/22

|

508

|

|

26

|

12/24

|

610

|

|

28

|

14 - 26

|

610

|

|

30

|

14 - 28

|

610

|

|

32

|

20 - 30

|

610

|

|

34

|

22 - 32

|

610

|

|

36

|

22 - 34

|

610

|

|

38

|

24 - 36

|

610

|

|

40

|

28 - 38

|

610

|

|

42

|

28 - 40

|

610

|

|

44

|

32 - 42

|

610

|

|

46

|

34 - 44

|

711

|

|

48

|

36 - 46

|

711

|

|

52

|

40 - 48

|

711

|

|

56

|

40 - 52

|

711

|

|

60

|

44 - 56

|

711

|

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :