ASTM A105 is a carbon steel forging standard developed by the American Society for Testing and Materials (ASTM). It is primarily used for the manufacture of flanges, fittings, valves, and other pressure-bearing piping components. This material is widely used in petroleum, chemical, power, and pressure piping systems, and is particularly suitable for carbon steel forged flanges and fittings.As a special steel, it belongs to the category of cold forged steel and is essentially a low-carbon steel forging with strict standard control of its chemical composition and mechanical properties. In terms of chemical composition, A105 material contains carbon (C) ≤ 0.35%, silicon (Si) ≤ 0.35%, manganese (Mn) 0.6-1.05%, sulfur (S) ≤ 0.050%, phosphorus (P) ≤ 0.040%, and limited content of copper, nickel, chromium, molybdenum and other elements. This precise composition ratio ensures that the material has good machinability while also having sufficient strength and toughness.

ASTMA105 Butt Weld Flange Size

The size of ASTM A105 butt welding flange varies due to different production standards. Common butt welding flange production standards are ASME B16.5, ASME B16.47, and EN1092-1.

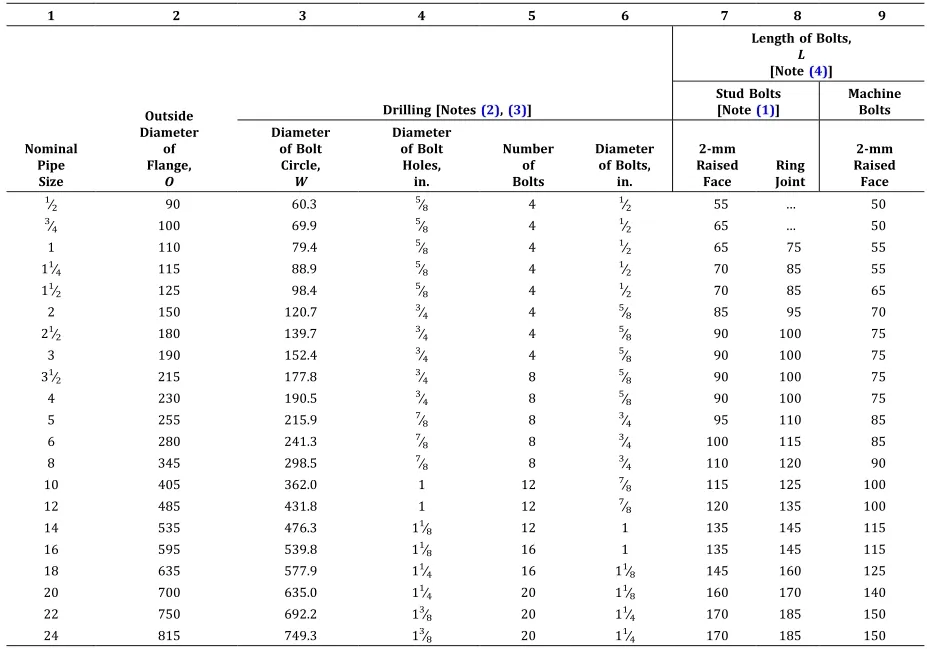

ASEM B16.5 is the production standard for American standard flanges, which includes flanges with sizes ranging from 1/2 inch to 24 inches and pressure ranges of CLASS150, 300, 600, 900, 1500, and 2500. It has relevant regulations on the size range, pressure level, tolerance range, representation, and detection methods of flanges.

ASME B16.5 CLASS150 flange size parameters

Advantages of ASTM A105 carbon steel forged butt welding large flanges:

1. Space saving: The design of large-size flanges can adapt to greater pressure and reduce the space requirements of pipelines, especially in some pipeline systems with limited space and high pressure.

2. Weight reduction: Large-size flanges can share more pipeline pressure coefficients and reduce the number of applications of small-size flanges, which helps to improve the portability and operability of the system.

3. Good sealing performance: The design of large-size flanges takes sealing performance into consideration, and through precise size and material selection, as well as suitable sealing rings or gaskets, reliable sealing effects can be provided.

4. High strength and rigidity: Large-size flanges usually have higher strength and rigidity, which enables them to maintain stable and reliable performance when subjected to harsh environments such as high pressure, high temperature and vibration.

5. Easy installation and maintenance: The design of large-size flanges makes them more convenient during installation and maintenance. For example, they can be assembled and disassembled with some special tools, and they can also be repaired and replaced more conveniently.

ASTM A105 carbon steel forged butt-welding large flange has a unique neck structure design. It is welded to the pipe through a tapered neck, which not only improves the strength and rigidity, but also effectively avoids thermal deformation of the sealing surface. It has a strict manufacturing process and a wide range of sizes. It is suitable for high temperature, high pressure and high sealing requirements. It is a key connector to ensure the safe and stable operation of the pipeline system.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :