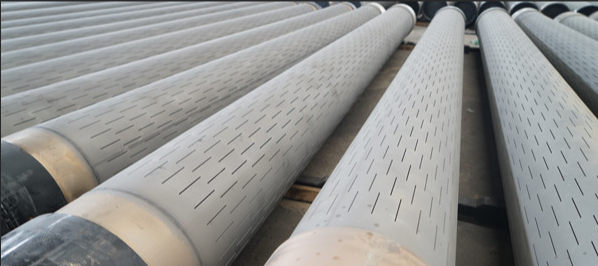

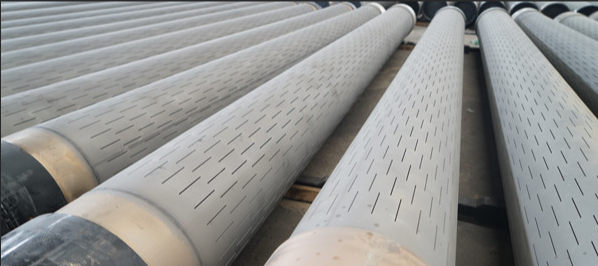

Slotted casing is widely used in oil exploration due to its excellent sand control efficiency, achieving up to 99% filtration. This efficiency significantly reduces maintenance costs while improving well strength, integrity, and sand control stability. Let us explore the details of slotted casing and its applications.

How Slotted Casing is Made

Slotted casing is crafted from high-strength steel pipes through either cold or hot processing methods. Advanced laser cutting technology is used to create thousands of longitudinal slots with high precision. The slots are smooth, burr-free, and have excellent vertical edge alignment. Though simple in design, slotted casing offers high operational efficiency and reliability in various drilling environments.

A central tube serves as the base of the slotted casing and is typically made from standard oil or casing pipes. The tube is perforated in a spiral pattern, minimizing the cross-sectional reduction. This design maintains overall flow area while ensuring the structural integrity of the pipe.

Slotted Casing Sand Control Technology

The slotted casing plays a pivotal role in gravel-packing sand control technology. This technique evolved from gravel-filled wire-wrapped screens and uses artificial gravel to form a bridge for blocking fine sand. The process involves combining slotted casing, sand filling tools, and tubular components. A slurry is injected into the annular space between the casing and the formation to create a stable filter layer.

The sand from the formation is blocked outside the slotted casing, while oil, gas, or water flows through the narrow slots into the casing. This efficient filtering mechanism makes slotted casings ideal for open-hole completions, cased-hole completions, and various well types, including vertical, deviated, and horizontal wells.

Material and Design Advantages

Slotted casing is commonly manufactured from J55 or N80 petroleum-grade casings. These materials provide high strength and resistance to deformation. The slots are evenly distributed along the pipe's axial direction, eliminating the need for an additional filter screen layer. This uniform distribution enhances the flow capacity, reduces operational complexity, and lowers costs.

Corrosion-resistant coatings are applied to the casing's surface, forming a dense protective layer. This treatment improves the casing's resistance to corrosion and wear, extending its service life in harsh downhole environments.

Comparison with Wire-Wrapped Screens

Compared to wire-wrapped screens, slotted casing offers several key benefits:

-

Higher Strength: The base material and structure ensure better durability under extreme conditions.

-

Larger Inner Diameter: This allows for easier configuration of tubular assemblies, improving operational flexibility.

-

Increased Sand Filling: The use of an extrusion filling process increases gravel placement compared to traditional circulation methods.

The application of laser cutting technology further enhances slot precision and structural reliability, ensuring effective sand control with minimal permeability reduction.

Key Features of Slotted Casing

-

Adaptability to Coarse Sand: Suitable for wells producing sand with particle sizes larger than 0.3 mm.

-

Enhanced Corrosion Resistance: Anti-corrosion treatment significantly improves durability.

-

Large Flow Area: A 2-7/8” slotted casing with 300 slots per 1.5 meters offers 2.4 times the flow capacity of standard oil pipes.

-

Strong Base Material: The J55 or N80 steel ensures the casing retains its shape and strength under pressure.

-

Ease of Configuration: Larger inner diameter supports seamless integration with other well components.

Applications of Slotted Casing

Slotted casing is versatile and suitable for various well completions, including:

-

Vertical, deviated, and horizontal wells.

-

Open-hole and cased-hole completions.

-

Sand-prone formations requiring high filtration efficiency.

Its efficient sand control mechanism, cost-effectiveness, and long service life make slotted casing an essential choice for the oil and gas industry.

Conclusion

Slotted casing continues to prove its value in oil exploration and production. Its advanced manufacturing, high strength, and sand control efficiency provide substantial benefits over traditional options. By combining innovative technology with practical design, slotted casing delivers reliable performance, making it a critical asset in achieving successful and sustainable well operations.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :