At present, there are many types of screen casing used in petroleum development in the world, and screen casing are widely used in petroleum development and application. It is understood that cutting, milling, drilling, beam and inlay methods are the most typical and most commonly used methods. Each has its own application scope and field. The quality of processing and production is different. The methods of drilling are different, so the screen casing used the types are also different. Screen casing is an important piece of equipment commonly used in the petroleum industry. Its main function is to filter solid particles trapped in the bottom during oil well production, while allowing oil, gas and other fluids to pass freely. It is usually installed inside the oil well pipe casing and is located at the bottom of the well to filter and protect the equipment. The working principle of the screen casing is to use the tiny pore size and pore structure on the screen casing to trap the solid particles in the fluid outside the tube, allowing only liquid or gas to pass through, ensuring that the fluid produced by the oil and gas industry is clean and pure. This can prevent solid particles such as sand and gravel from entering the oil pipe or gas pipe, clogging the pipeline and affecting production efficiency.

The screen casing is a device used to filter solid particles at the bottom of the well while allowing oil, gas and other fluids to pass freely. Its main functions include:

The working principle of the screen casing can be divided into the following steps:

Fluid entry: The fluid containing a mixture of solid particles passes through the screen casing.

Solid particle interception: Solid particles are blocked by the filaments on the surface of the screen casing and cannot pass through the screen casing gap, and are trapped outside the screen casing .

Clean fluid passes: The fluid (usually liquid or gas) filtered by the screen casing can pass freely through the gap between the wire windings and become purer.

Accumulation of solid particles: Solid particles trapped outside the screen casing gradually accumulate to form blocking materials, but do not affect the normal passage of fluid. Its working principle is to use the microporous structure of the screen casing to block the solid particles in the fluid outside the tube and only allow the fluid to pass through. This working principle ensures the efficiency and reliability of the screen casing during the filtration process.

The oil screen casing is a device used to filter solid particles at the bottom of the well, while allowing oil, gas and other fluids to pass freely. It mainly includes the following functions:

Filter solid particles: Prevent solid particles such as sand, gravel, and sediment from entering the oil pipe or air pipe and blocking the pipeline.

Protect the oil layer: prevent external impurities from entering the well and protect the productivity and production efficiency of the oil layer.

Improve productivity: Improve the productivity of oil wells by effectively filtering solid particles and ensuring that fluids can flow smoothly from underground reservoirs into the wellbore.

Its working principle is to use the microporous structure of the screen casing to block the solid particles in the fluid outside the tube, allowing only the fluid to pass through. This working principle ensures the efficiency and reliability of the screen casing during the filtration process.

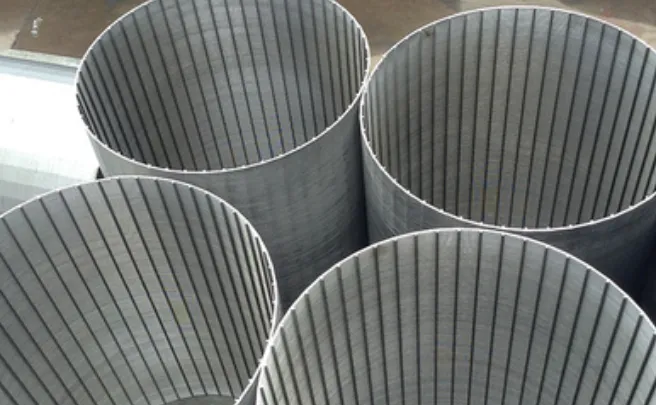

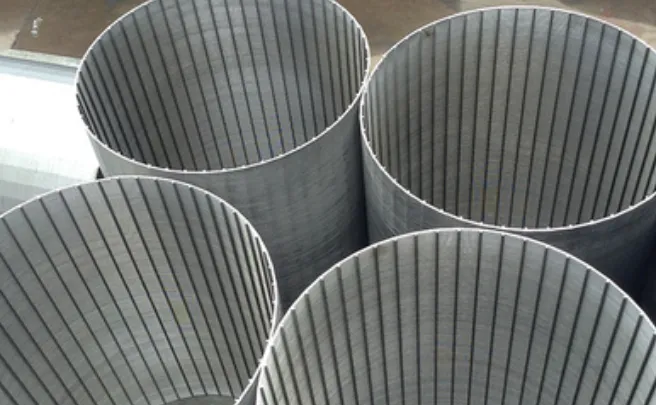

Screen casing manufacturing

The screen casing is made by winding steel wires of a certain cross-section around a metal liner with holes evenly distributed on the surrounding screen bars or openings and welding them firmly, leaving a certain gap as a screen hole. Although this manufacturing method has been used by many manufacturers, this screen casing has some problems when it is lowered into the well. Especially when it is forced to pass through the curved section of a highly deviated well or a horizontal well, it inevitably has to come into contact with the well wall or casing. Collisions, extrusions and frictions can easily lead to the phenomenon of "tangled wires", causing screen casing damage or gap deformation, resulting in reduced completion quality and sand control effect or failure. To address this drawback of wire-wound screens, pipes and seams are integrated. Slotted casing were developed and were more affordable.

Technical innovation of petroleum screen casing

With the development of the petroleum industry, petroleum screen casing technology is also constantly innovating and progressing. The application of new technologies has significantly improved the efficiency, corrosion resistance and adaptability of oil screens casing. For example, material innovation and modern technology development adopt new materials that are resistant to high temperatures and corrosion, which will help improve the service life and adaptability of screen casing. Some companies also optimize the structural design of the screen casing to increase the filtration area and filtration precision, which is beneficial to filtration efficiency. The second step is to introduce self-cleaning technology to reduce the possibility of screen casing clogging and extend the service life of the screen casing.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :