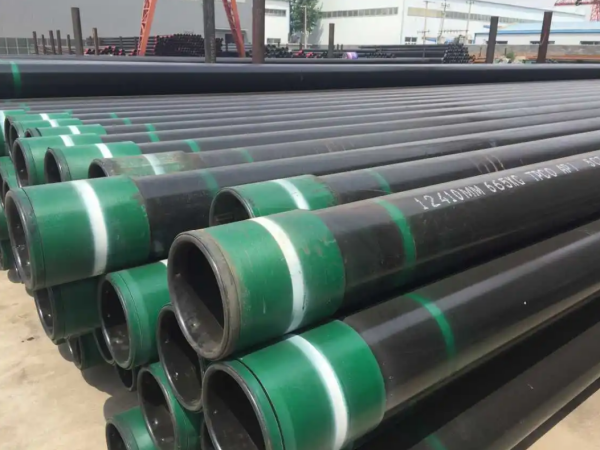

Water well casing is an essential structural component in water well systems, primarily used to maintain the stability of the wellbore and prevent well collapse, while safeguarding the water source from external contaminants. These casings, typically made of steel, PVC, or fiberglass, are vertically installed during drilling operations, extending from the surface to the bottom of the well. The importance of water well casing lies not only in supporting the well structure but also in effectively protecting water wells by ensuring safe and clean water supply.

Water well pipe casing is not only used in water wells, but also widely used in gas wells and oil wells to play a structural fixation role. After installation, it can always maintain the stability of the underground formation while allowing drilling operations, liquid circulation and water resource extraction. The casing pipe is designed to withstand high-pressure environments and ensure the long-term stability of the well.

Water well pipe casing of different materials

Water well pipe casing can be made of a variety of different materials, and the specific choice depends on the purpose, depth, geological conditions and required durability of the well. Common materials include:

Steel pipe: suitable for deep wells, especially deep wells (more than 300 meters), and

seamless steel pipes are usually required. Steel pipes are widely used in all types of wells due to their strength and durability, especially in water supply wells, where they have the longest service life.

Cast iron pipes: Commonly used in large-diameter shallow water supply wells, they have good pressure resistance, but are relatively heavy.

PVC pipes: PVC pipes are often used in shallow wells due to their light weight, corrosion resistance, and affordability. It is a popular choice, especially for environments that do not require extremely high strength.

Cement asbestos pipes and ceramic pipes: These pipes are also commonly used in agricultural irrigation wells and water supply wells.

FRP pipes: Despite their corrosion resistance, FRP pipes are not usually used in wells for domestic water due to drinking water hygiene issues. In addition, the cost of FRP pipes is relatively high, so they are less used.

Among these materials, steel pipes remain the most widely used material due to their long service life and strength.

Sizes and specifications of water well pipe casings

The size of water well pipe casings is key to their functionality and suitability. Common outer diameters range from 33.4 mm to 323.9 mm, with wall thicknesses between 3.2 mm and 9.5 mm. The length of water well pipe casing is usually between 6 meters and 18.3 meters, depending on the depth of the well and the requirements of use.

Production standards and material quality are also important criteria for water well pipe casing selection. Common production standards include ASTM A 589 I, II, III, IV types, where different standards are applicable to different well depths and pressure conditions. In addition, the casing material is usually selected from Class A or Class B materials, which have the characteristics of weldability and threaded connection.

During the production and installation process, water well pipe casing must also pass a number of tests to ensure its quality, including:

Visual and dimensional inspection

Leakage and sealing tests (such as hydrostatic test, eddy current test)

Destructive tests (such as flattening, bending test)

Mechanical property testing

Chemical composition analysis

Metallurgical inspection

Depending on the customer and industry standards, it is usually also necessary to issue corresponding certificates in accordance with the requirements of EN 10204 2.1, 2.2, 3.1, 3.2.

Correct technology for installing water well casing

Correct installation technology is essential for the long-term use of water well casing. First, proper installation ensures the structural integrity of the casing, preventing the wellbore from collapsing or being damaged. In addition, the installation process should ensure that the casing is accurately sized and properly centered within the wellbore to avoid uneven stress distribution or casing failure.

Another important function of water well pipe casing is to protect the water quality in the well. By isolating the water from the surrounding soil and possible contaminants, the water well pipe casing plays a vital role in ensuring the purity of the water source.

How to choose the right water well pipe casing?

Choosing the right water well casing is not just a technical issue, it directly affects the life of the well and the safety of the water supply. Here are some key factors to consider when choosing a casing pipe:

Well depth: Deeper wells require thicker and stronger casing pipe to withstand higher underground pressures.

Soil conditions: Some areas have more corrosive or abrasive soils, so it is necessary to choose a casing pipe material that can withstand these factors. For example, in soft soil areas, PVC or other non-corrosive materials may be a better choice.

Water quality: Certain minerals or chemicals in the water may affect the choice of casing pipe. The right casing pipe material can prevent water quality from deteriorating or contaminating.

Maintenance and management of water well casing

Regular inspection and maintenance of water well pipe casing is the key to ensure its long-term stability and functionality. Through regular visual inspection and pressure testing, engineers can detect damage or wear of the casing pipe in time to avoid bigger problems. In addition, appropriate anti-corrosion treatment and sealing measures can also effectively extend the service life of the casing.

Conclusion

Selecting the right

well casing and installing it correctly are key steps to ensure the long-term stable operation of the well system and protect the water source. By selecting corrosion-resistant casing materials, reasonable size design, and ensuring that it meets local soil conditions, water quality requirements and regulatory standards, the service life of the well can be effectively extended and the subsequent maintenance costs can be reduced. Whether it is a household water supply well, an agricultural irrigation well, or a deep well, the selection and installation of the well casing are crucial to ensure clean and safe water supply and avoid pollution risks.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :