Carbon steel (cs) pipe is one of the most widely used materials in industrial piping systems. The reasonable determination of its pressure level is directly related to the safe operation and economic cost of the piping system.Understanding the CS pipe pressure rating is essential for engineers and buyers alike. Carbon steel pipes are widely used in industrial and commercial systems. Their strength, affordability, and durability make them a top choice.Calculating the pressure rating of carbon steel (CS) pipes is critical in industrial and engineering applications. Proper calculation helps ensure safety, prevent system failures, and select the right materials for the job.

What Is CS Pipe Pressure Rating?

The pressure rating of a carbon steel pipe refers to the maximum internal pressure it can safely withstand. This rating depends on several factors, including pipe diameter, wall thickness, material grade, and operating temperature.

To put it simply, the higher the pressure rating, the more demanding the application it can support. Choosing the right pressure rating helps avoid leaks, bursts, and failures in critical systems.

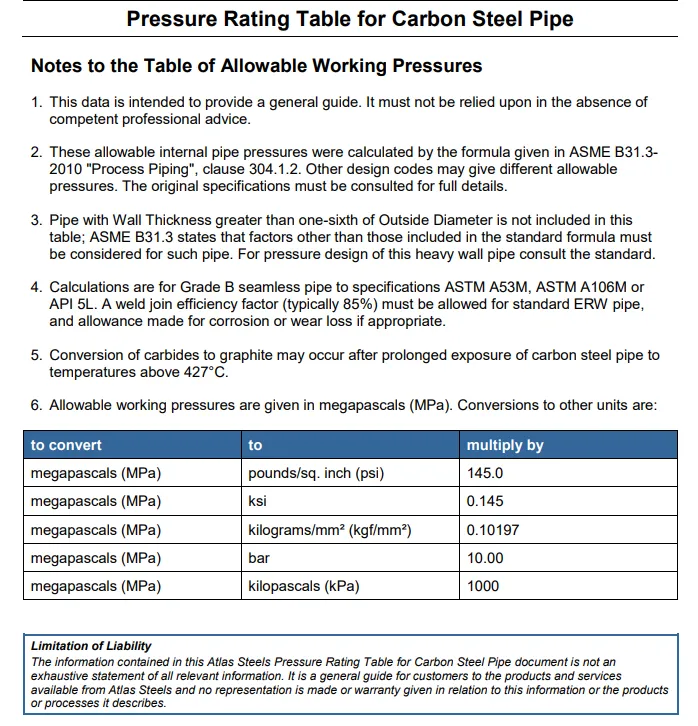

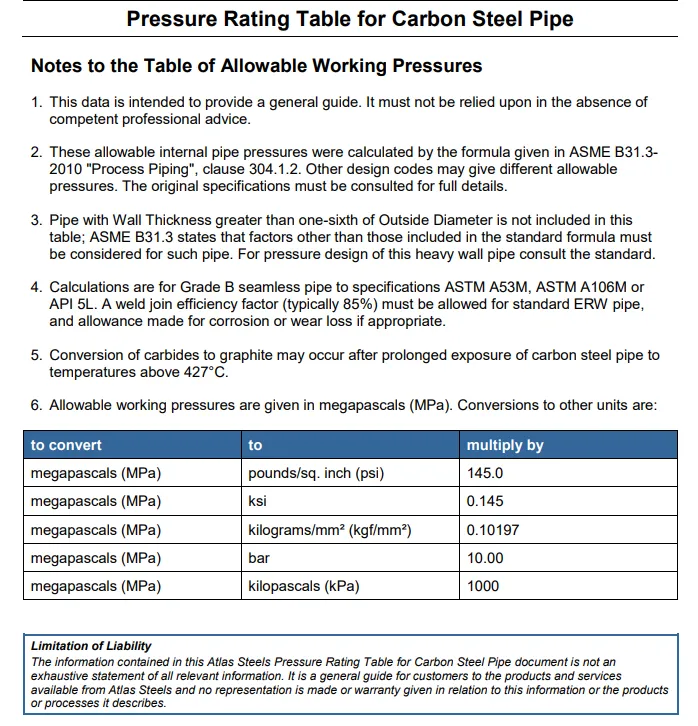

Pressure Rating Standards for CS Pipes

Several international standards define pressure ratings for carbon steel pipes. These include:

ASME B31.3 (for process piping)

ASME B36.10M (dimensions and schedules)

API 5L (pipeline transportation systems)

ASTM A106/A53 (seamless and welded steel pipes)

These standards provide formulas and tables to help calculate or verify the pressure capacity of specific pipe types under various conditions.

CS Pipes Pressure Rating Table

How to Calculate CS Pipe Pressure Rating

Although engineers often refer to standards, it’s helpful to understand the basic formula:

P = (2 × S × t) / (D – t)

Where:

P is internal pressure

S is allowable stress

t is pipe wall thickness

D is outside diameter

Keep in mind, this is a simplified version. Design codes may introduce safety factors or temperature adjustments.

In engineering design practice, the following practical formulas are commonly used to calculate the rated pressure of carbon steel pipelines:

1. Simplified mid-diameter formula: P = (2[σ]^t·t)/(D-t). This formula is suitable for preliminary estimates and thin-walled pipe (t < D/6). This formula ignores weld factors and temperature corrections and is therefore conservative.

2. Complete wall thickness formula: t = (P × D) / (2[σ]^t × φ + 2P × Y) + C. This is the standard calculation method recommended by GB/T 20801 and ASME B31.3, taking into account weld strength, temperature effects, and corrosion allowance.

3. Pipe schedule (Sch) and pressure relationship: Sch = P × 1000 / [σ]^t. Pipe schedule is the ANSI standard for indicating wall thickness series. This formula can be used to convert design pressure to standard wall thickness grades. For example, for ASTM A53 carbon steel pipe ([σ]^t = 30,000 psi ≈ 205 MPa), when P = 1,200 psi ≈ 8.27 MPa, Sch = 1,200 × 1,000 / 30,000 = 40, meaning Sch 40 pipe should be selected.

4. Test Pressure Calculation Formula: According to GB 50235 and ASME B31.3, the hydraulic test pressure is generally 1.5 times (but not less than 1.25 times) the design pressure, taking temperature correction into account: P_test = 1.5 × P × ([σ]_test / [σ]^t), where [σ]_test is the allowable stress at the test temperature.

5. External Pressure Stability Formula: When a pipeline is subjected to external pressure (such as in a vacuum or buried pipeline), the rated pressure is related not only to the material strength but also to the geometric stability of the pipeline. The critical buckling pressure under external pressure can be calculated as P_cr=2E/(1-ν^2)×(t/D)^3, where E is the elastic modulus and ν is the Poisson's ratio

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :