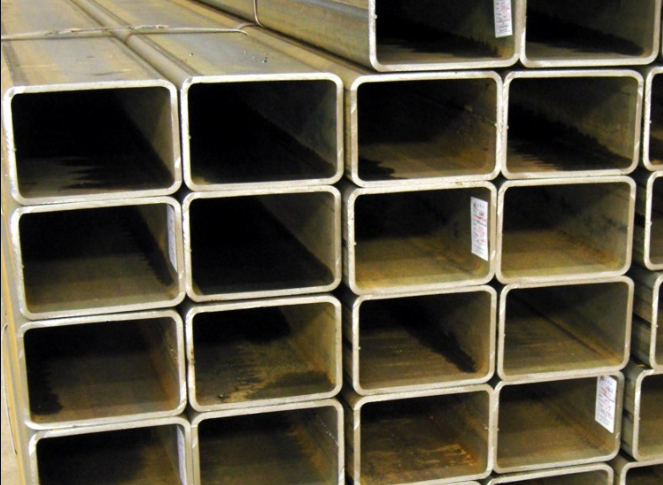

Identifying counterfeit rectangular tubes requires careful observation and knowledge. First, we need to understand the basic characteristics and quality standards of rectangular tubes, and then use some practical methods and techniques to judge their authenticity. The following is a possible discussion, including the definition, characteristics, quality standards of rectangular tubes, and methods to identify fake and inferior rectangular tubes.

1. Basic definition and characteristics of rectangular tube

Rectangular tube is a common construction material, usually used to make bridges, building structures, mechanical equipment, etc. Its basic characteristics include:

The shape is rectangular, with two dimensions: length and width.

The thickness is uniform with no obvious unevenness or deformation.

The surface is smooth with no cracks, bubbles or obvious blemishes.

Rectangular tubes, like square tubes, are usually made of carbon steel, alloy steel, stainless steel and other materials.

2. Quality standards for rectangular tubes

The quality standards of rectangular tubes usually include the following aspects:

Dimensional standards: The length, width, and thickness of rectangular tubes should comply with the size range specified by national or industry standards.

Material standards: The material of rectangular pipes should comply with relevant standards. For example, steel should comply with national standards for strength, corrosion resistance and other indicators.

Surface quality: The surface of the rectangular tube should be smooth and flat, without obvious scratches, bubbles or rust.

Testing standards: The quality testing of rectangular tubes should comply with relevant standards, such as ultrasonic testing, magnetic particle testing, etc.

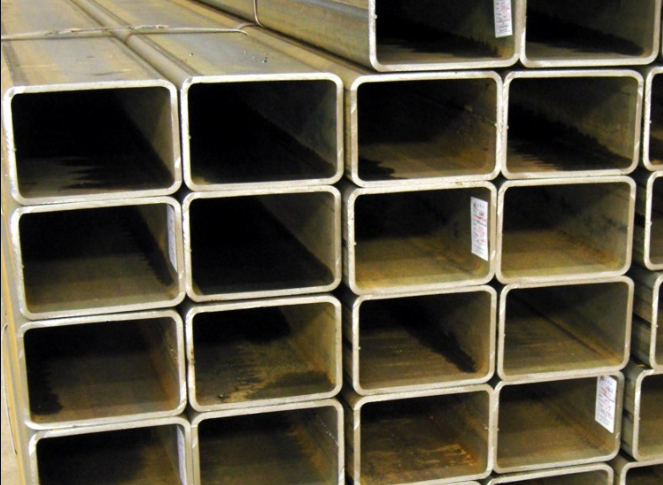

3. How to identify fake and inferior rectangular tubes

In order to identify fake and inferior rectangular tubes, we can adopt the following methods and techniques:

Observe the appearance:

Appearance quality: Fake rectangular tubes usually have poor appearance quality and may have obvious unevenness, bubbles, cracks and other problems.

Surface treatment: Genuine rectangular pipes usually undergo surface treatment, such as painting, galvanizing, etc., while fake products may only have simple treatment or no treatment at all.

Identification label: Rectangular tubes produced by regular manufacturers usually have identification labels, which contain information such as manufacturer, specifications, batch number, etc., while fake products may not have them or the identification may not be clear.

Test quality:

Measure the size: Use tools such as rulers or calipers to measure the actual size of the rectangular tube and compare it with the standard size.

Check the surface: Carefully observe whether the surface of the rectangular tube is smooth and has no obvious flaws.

Material testing: You can use metal material testing instruments to test the material of the rectangular tube to ensure that it meets the standard requirements.

Check the certificate:

Product certificate: Rectangular tubes produced by regular manufacturers usually come with a product certificate, which contains relevant testing information, and its authenticity can be verified by query.

Through the above methods and techniques, we can relatively accurately identify fake and inferior rectangular pipes, ensure the use of building materials that meet quality standards, and ensure project quality and safety.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :