The oil casing pup joint is a short length of oil casing, which is mainly used to adjust the height and depth of the oil well casing string. It is also widely used to adjust the position of downhole tools. As an important component for connecting and adjusting the length of the oil well casing string, its manufacturing and specifications must comply with the API5CT industry standard. It is made of specific steel, usually special steels such as J55 and N80Q, to ensure its pressure resistance and corrosion resistance in complex oil well environments. The pup joint is mainly used to adjust the height of the full-length oil pipe or casing string. It has the same steel grade and threaded connection type as the oil pipe and casing, but it is shorter in length. This article will introduce its size and specifications.

API pup joint size standards

Size and appearance quality: According to SY/T6194-96 standard, the size of oil casing pup joint is usually 304mm, 139mm, 204mm and other indefinite lengths, and the diameter is generally 153.5mm, 140.5mm, 136.5mm, etc. It can also be customized according to customer requirements

Outer diameter of pup joint: 4 ½ inches – 13 3/8 inches

Typical length of pup joint: 1, 2, 3, 4, 6, 8, 10, 12 feet

Standard API casing pipe sizes include:

1.050 inches (26.7 mm)

1.315 inches (33.4 m)

1.660 inches (42.2 mm)

1.900 inches (48.3 mm)

2.375 inches (60.3 m)

2.875 inches (73.0 m)

3.500 inches (88.9 m)

4.000 inches (101.6 m)

4.500 inches (114.3 mm)

These dimensions are specified in API Specification 5CT, the industry standard for casing pipe and pipe joints used in oil and gas wells.

Technical standards and specifications

According to the API5CT standard, the manufacture and use of oil casing pup joints must meet the following technical standards and specifications:

Material selection: Oil casing pup joints are usually made of specific steels such as J55 and N80Q. Their chemical composition must meet the requirements of the API5CT standard. The sulfur and phosphorus content must not exceed 0.045%, and the arsenic content must not exceed 0.15%. Appearance quality requires that there are no defects such as folds, cracks, and scars on the inner and outer surfaces. Surface defects can be removed by filing, grinding wheels, etc., but the removal depth must not exceed 12.5% of the nominal wall thickness.

Manufacturing method: The manufacturing method is similar to that of seamless pipes, including hot rolling, cold rolling and other processes to ensure that the pipe surface is smooth and has no obvious defects.

Physical performance test

The physical performance test of oil casing pup joints includes tensile test and water pressure test. The tensile test is carried out according to GB228-87 standard to ensure that its yield strength and tensile strength meet the requirements of API5CT standard. The water pressure test sets the corresponding test pressure according to the steel grade and diameter of the pipe to verify its pressure resistance.

Application and market demand

Oil casing pup joints are widely used in the oil and gas extraction industry. Its main function is to adjust the length of the oil well casing string to meet the needs of different well depths and well types. Its advantages include simple structure and easy installation, which can effectively improve the production efficiency and safety of oil wells.

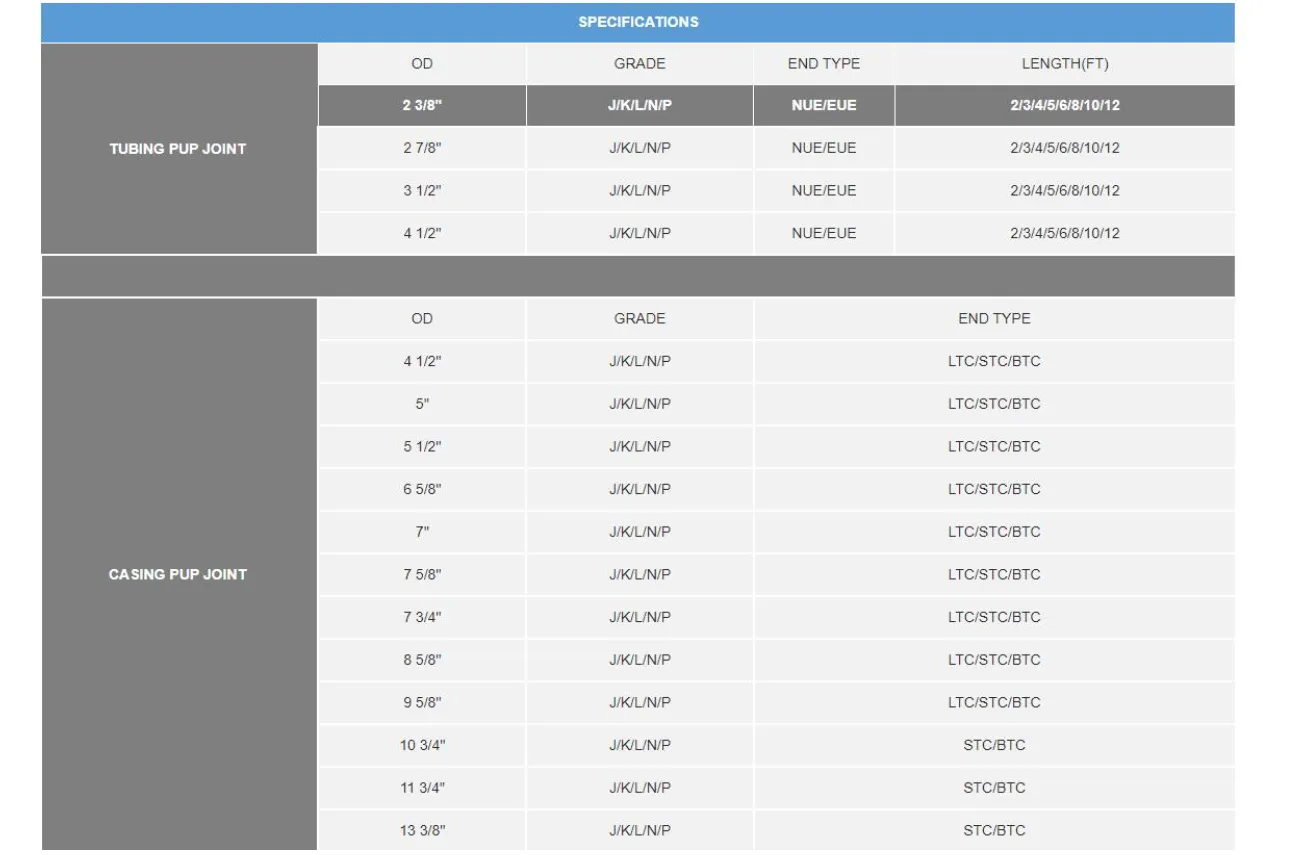

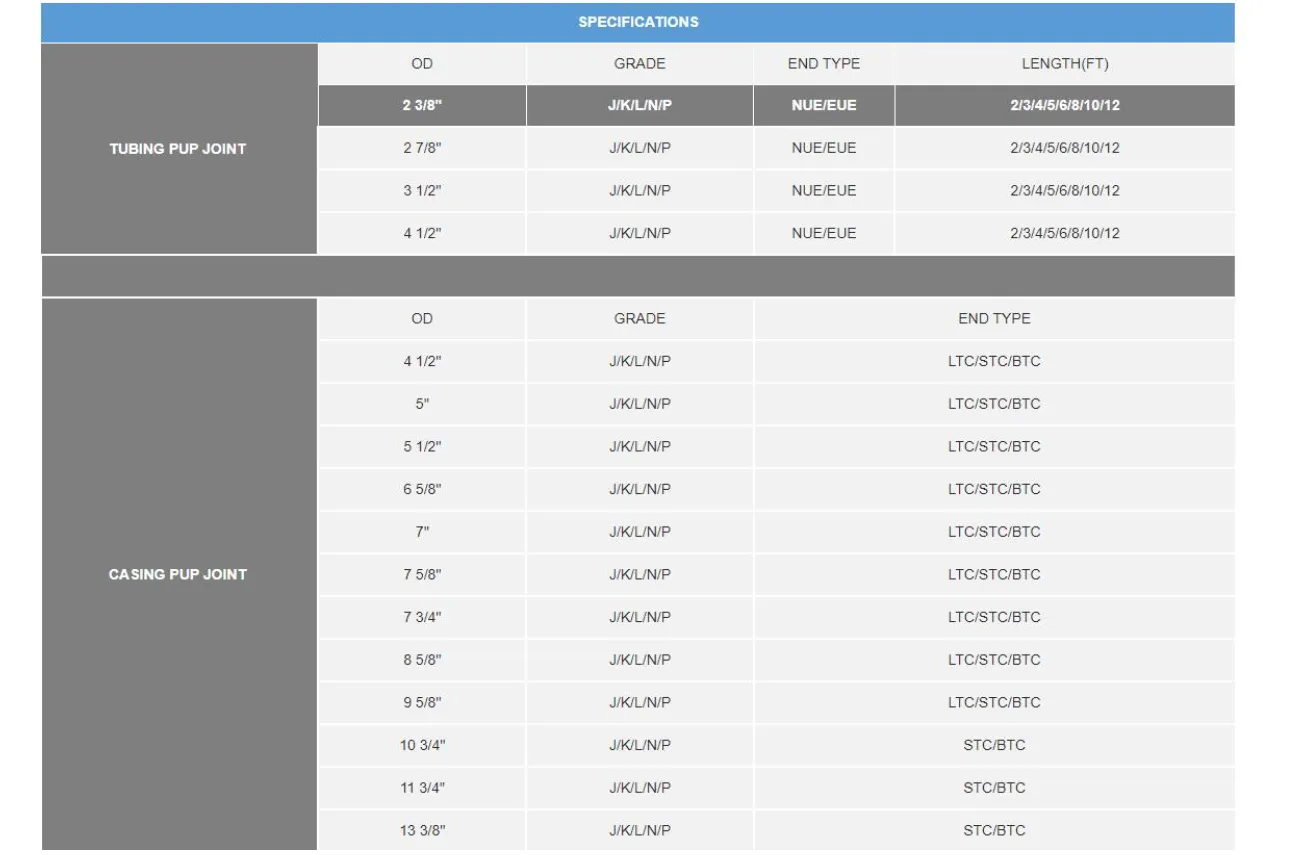

Pup joint specification chart:

Conclusion

The development of today's oil extraction work is very complete. The size of the pup joint sometimes becomes diverse due to customer customization. BAOWI STEEL MANUFACTURING specializes in providing high-quality pup joint products, which can provide optional diameters, lengths, weights and grades according to your requirements. Our quality can stand the test of time, and our products can withstand careful scrutiny. If you need it, you can contact us at any time

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :