Small-diameter seamless steel pipe refers to seamless steel pipe with a smaller outer diameter, usually referring to steel pipe with an outer diameter below 89mm and above 4mm. It can be divided into two categories: seamless small-diameter steel pipe and straight-seam small-diameter seamless steel pipe (also called welded small-diameter seamless steel pipe). Small-diameter seamless steel pipe is a round, square, or rectangular steel with a hollow cross-section and no seams around it. Seamless steel pipes are made by perforating steel ingots or solid tubes into rough pipes, and then hot-rolled, cold-rolled, or cold-drawn. Seamless steel pipes have a hollow cross-section and are widely used as pipes for conveying fluids. Compared with solid steel such as round steel, steel pipes are lighter in weight when the bending and torsional strengths are the same. They are an economical cross-section steel and are widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile drive shafts, bicycle frames, and steel scaffolding used in construction.

1.Characteristics of small-diameter seamless steel pipes

Hollow section: Steel pipes with hollow sections are lighter than solid steel and more economical when the bending and torsional strengths are the same.

No seams: Since there are no welded seams, the structure is more uniform and can withstand higher pressures and loads.

Widely used: Suitable for pipelines for conveying fluids (such as water, oil, gas, etc.), manufacturing structural parts and mechanical parts (such as oil drill pipes, automobile transmission shafts, bicycle frames, building scaffolding, etc.).

2.The advantages of small-diameter seamless steel pipes include:

High dimensional accuracy: small-diameter seamless steel pipes have high outer diameter dimensional accuracy and uniform wall thickness distribution, which can ensure operation under a certain flow rate and pressure.

Good corrosion resistance: Since small-diameter seamless steel pipes are usually used to transport liquids or gases, their corrosion resistance is very good, which can ensure the purity and stability of liquids or gases.

High reliability: In the production and manufacturing of small-diameter seamless steel pipes, high-quality steel and advanced production processes are generally used to ensure their reliability and safety.

Good economic efficiency: Since small-diameter seamless steel pipes have lower material and production costs and relatively lower prices than large-diameter seamless steel pipes, they have better economic efficiency.

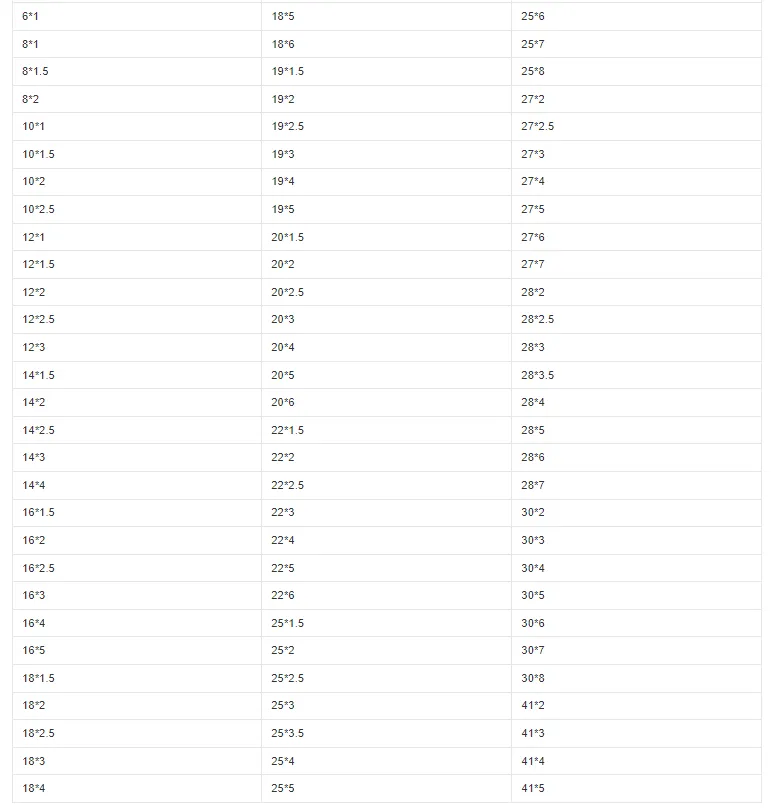

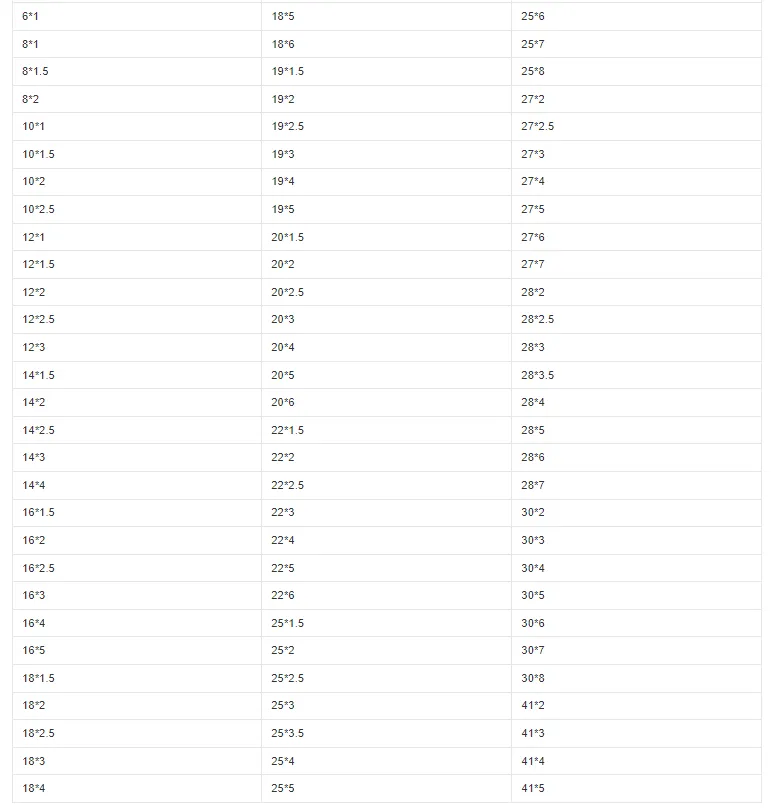

3.Specifications of small-diameter seamless steel pipes:

The specifications of seamless steel pipes are usually expressed by outer diameter * wall thickness (unit: mm). Seamless steel pipes can be divided into two categories according to the production method: hot-rolled seamless steel pipes and cold-rolled (drawn) seamless steel pipes. Hot-rolled seamless steel pipes are divided into general steel pipes, low- and medium-pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes. In addition to general steel pipes, low- and medium-pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, and other steel pipes, cold-rolled (drawn) seamless steel pipes also include precision steel pipes, carbon thin-walled steel pipes, alloy thin-walled steel pipes, stainless steel thin-walled steel pipes, special-shaped steel pipes, etc. The outer diameter of hot-rolled seamless pipes is generally greater than 32mm, and the wall thickness is 2.5-75mm. The outer diameter of cold-rolled seamless steel pipes can reach 6mm, and the wall thickness can reach 0.25mm. The outer diameter of thin-walled pipes can reach 5mm and the wall thickness is less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling. In pipeline engineering, hot-rolled pipes are often used when the pipe diameter exceeds 57mm, and cold-drawn (rolled) pipes are often used when the pipe diameter is less than 57mm.

4.The materials of small-diameter seamless steel pipes are as follows:

10#, 20#, 35#, 45#, 16Mn, 27SiMn, 15CrMo, 12Cr1MoV, 10CrMo910, T91, P91, J55, K55, Q345A, Q345B, Q345C, Q345D, Cr5Mo2, etc.

5.Uses of small-diameter seamless steel pipes

The application fields of small-diameter seamless steel pipes are also very wide. For example, in the supporting network industries such as petroleum, chemical industry, and electric power, small-diameter seamless steel pipes are often used to transport media such as oil, gas, water, and steam. In the fields of machinery manufacturing, automotive parts, aerospace, etc., small-diameter seamless steel pipes can be used as manufacturing materials for mechanical parts. In the fields of construction, bridges, etc., small-diameter seamless steel pipes

In short, small-diameter seamless steel pipes are a kind of pipeline material with a wide range of applications. Their advantages such as high strength, high pressure resistance, corrosion resistance and easy welding make them widely used in the fields of petroleum, chemical industry, electricity, machinery, aviation, aerospace, etc. With the continuous advancement of science and technology and the continuous expansion of application fields, the demand for small-diameter seamless steel pipes will continue to increase, and their application prospects are very broad.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :