Seamless High-Pressure Boiler Tubes

Against the backdrop of my country's rapid economic growth, the electric power industry, as a foundational industry, has experienced rapid development. Electricity is not only a source of power for industrial production but also a vital guarantee for people's daily lives. With increasing energy demand and the widespread construction of thermal power plants, the demand for high-pressure boiler tubes has steadily increased. As a key component of power plant boilers, seamless high-pressure boiler tubes play an irreplaceable role in energy equipment manufacturing.

High-pressure boiler tubes are a type of seamless steel pipe designed to withstand extreme conditions of high temperature, high pressure, and corrosive environments. They are mainly used in power plants, chemical industries, and energy equipment to manufacture boiler components such as superheaters, reheaters, and water wall tubes. Made from high-quality carbon steel, alloy steel, or heat-resistant stainless steel, these tubes undergo strict heat treatment and testing to ensure durability, oxidation resistance, and structural stability during long-term operation.

1.Concept and Characteristics of Seamless High-Pressure Boiler Tubes

Seamless high-pressure boiler tubes are special-purpose seamless steel tubes primarily used in the manufacture of high-pressure, ultra-high-pressure, and even subcritical and supercritical thermal power generation boilers. Compared to ordinary seamless steel tubes, their greatest advantage lies in their ability to withstand complex operating conditions such as high temperatures, high pressures, and corrosive media for extended periods. Consequently, extremely stringent requirements are placed on their material, performance, and production processes.

This type of steel tube possesses the following basic characteristics:

High high-temperature pressure bearing capacity: Capable of long-term operation at temperatures between 400°C and 700°C.

Excellent oxidation and corrosion resistance: Resistant to oxidation and corrosion in high-temperature flue gas and steam environments.

Good Microstructure Stability: After rigorous heat treatment, the grain size and microstructure remain stable, reducing embrittlement and performance degradation during long-term use.

Both Strength and Toughness: Not only must the tube possess sufficient long-term strength, but it must also ensure impact and fatigue resistance.

2. Production and Testing Requirements for Seamless High-Pressure Boiler Tubes

The production process for seamless high-pressure boiler tubes is similar to that for ordinary seamless steel pipes, but with more stringent requirements in tube blank selection, forming, heat treatment, and inspection.

Raw Material Requirements: High-quality carbon structural steel, alloy structural steel, or stainless heat-resistant steel is used as the tube blank to ensure high purity and microstructure uniformity.

Production Process: This includes piercing, hot rolling, cold drawing, or heat treatment, with strict control of microstructure and properties.

Testing Requirements: Each finished steel tube must undergo hydrostatic testing, expansion testing, and flattening testing to ensure it will not leak or rupture under high-pressure conditions.

Delivery Condition: Steel tubes are generally delivered in the heat-treated state. Common treatments include normalizing, tempering, or quenching and tempering.

Microstructure control: The microstructure, grain size and decarburized layer of the finished pipe need to be tested to ensure that the performance meets national standards.

3. Common Steel Grades and Standards of Seamless High-Pressure Boiler Tubes

Seamless high-pressure boiler tubes are made of carbon steel, alloy steel, and stainless heat-resistant steel. Different steel grades are suitable for different operating conditions:

Carbon structural steels such as 20G, 20MnG, and 25MnG are suitable for medium- and low-pressure boilers.

Alloy structural steels such as 15MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12Cr1MoVG, and 12Cr3MoVSiTiB are suitable for high-temperature and high-pressure boilers.

Stainless heat-resistant steels such as 1Cr18Ni9 and 1Cr18Ni11Nb are suitable for ultra-high-temperature environments.

The primary standard implemented is GB5310-1995 "Seamless Steel Tubes for High-Pressure Boilers." Specifications range from an outer diameter of 16 to 824 mm and a wall thickness of 2 to 65 mm.

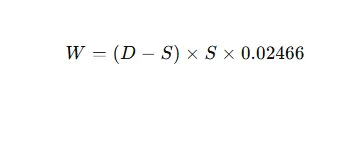

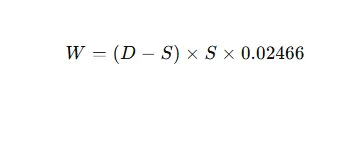

The weight calculation formula is:

Where: D is the outer diameter and S is the wall thickness.

Seamless high-pressure boiler tubes are primarily used in the energy equipment manufacturing sector, with typical applications including:

Thermal power plants: Used in the manufacture of superheater tubes, reheater tubes, water-wall tubes, and economizer tubes for high-pressure and ultra-high-pressure boilers.

Chemical equipment: Used in pressure vessels and high-temperature heat exchange equipment to transport high-temperature, high-pressure steam and corrosive media.

Petrochemical industry: Suitable for special operating equipment such as oil cracking units and high-temperature reactors.

Metallurgy and machinery: Used as key components in high-temperature pressure piping and thermal equipment.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :