What is the difference between slotted casing and screen casing?

Slotted casing and screen casing are two pipe structures commonly used in oilfield drilling and oil well completion. They have some significant differences in function and application. Slotted casing is usually used to control the seepage of the formation around the wellbore and prevent impurities such as sand and debris. Enter the wellbore while allowing target substances such as oil and water to pass through. This kind of casing is characterized by a series of open elongated slots on its surface. The size and distribution of these slots can be designed and processed according to specific formation characteristics and engineering needs to achieve the best seepage control effect.Screen casing is a pipeline structure that achieves filtration and separation by installing special screens or screen tubes on the casing wall. This type of casing is typically used where finer filtration and control is required, such as controlling the ingress of fine particles or removing impurities from groundwater. The screen mesh of the screen tube sleeve can be selected with different mesh sizes and densities according to needs to achieve the best filtration effect. Screen casing and slotted casing are two common pipeline products in the petroleum industry. They have some differences in structure and use. This article will introduce their different structures and uses in detail.

Slotted casing and screen casing structural differences

Screen casings: Screen casings usually have mesh or mesh structures and are used in oil wells to filter oil and natural gas from reservoirs. Its main feature is that there are holes or meshes on the pipe wall. These holes or meshes can filter out solid particles of different particle sizes and allow the fluid to pass through. The structure of the screen casing makes it suitable for oil well water injection, oil well production and other environments to control the oil-water ratio or prevent solid particles from entering the oil layer.

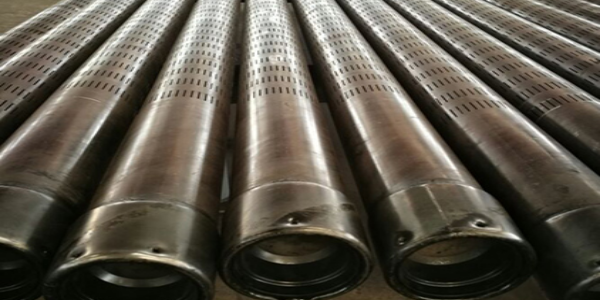

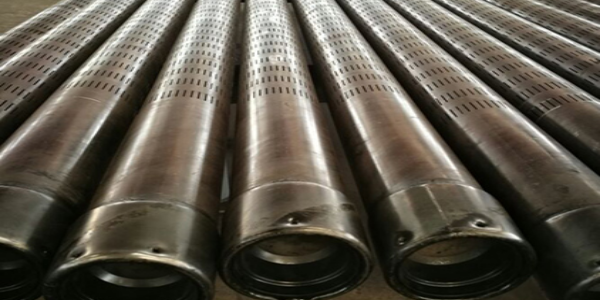

Slotted casing: Slotted casing refers to a pipeline product that has grooves on the surface of the casing to form a channel structure. The slotted structure of slotted casing can be linear or staggered, and is usually used to increase the strength of the pipe wall and improve the sand control stability of oil and water wells. The main function of slotted casing is to improve the functional performance of the casing, such as increasing the permeability of the pipeline, preventing scale accumulation on the pipe wall, and improving the strength and integrity of the pipeline.

Slotted casing and screen differences in use:

Applications of screen tube casing:

Filtration and screening: Screen casings are mainly used in underground projects such as oil wells and natural gas wells as devices for filtering and screening oil, gas, water and other substances. Their main function is to filter out solid particles, gravel and other impurities in oil layers or natural gas, protect oil and gas well equipment, and maintain the quality and stability of oil and gas output.

Control the oil-water ratio: During the water injection or oil production process in the oil field, screen casings can also be used to control the oil-water ratio, prevent oil-water mixing, and improve oil production efficiency.

Protect the oil layer: The screen casing can also protect the integrity of the oil layer, prevent solid particles from entering the oil layer, and reduce sediment damage to the oil layer.

Applications of slotted casing:

Increase permeability: Slotted casing is mainly used to increase the permeability of pipelines and improve the sand control stability of oil and water wells. By grooving the surface of the casing, the permeability of the pipeline can be increased, making the fluid flow in the pipeline smoother.

Improve pipeline strength: The slotted structure of slotted sleeves can increase the strength and integrity of the pipeline and reduce the risk of pipeline deformation and breakage.

Improved functional performance: In addition to increasing permeability and improving pipe strength, grooved casing can improve the sand control stability of the pipe, reduce the accumulation of sediment in the pipe, and extend the service life of the pipe.

Therefore, screen casings are mainly used for filtration and screening in underground projects such as oil wells and natural gas wells, while slotted casings are mainly used to increase permeability, strength and functional performance in pipelines. Their application scenarios and functional purposes are different, and the choice of which type of casing to use needs to be based on specific engineering needs and pipeline design.

Slotted casing and screen casing Corrosion resistance

Screen casing: Since screen casing is often exposed to high temperature, high pressure, corrosive media, etc., its coating needs to have high corrosion resistance and be able to maintain stability and reliability in harsh environments for a long time.

Grooved casing: The anti-corrosion coating of grooved casing is generally aimed at general use environments, and its corrosion resistance requirements are relatively low, mainly to prevent corrosion damage in conventional environments.

Comparison of cost performance between slotted casing and screen casing

Slotted Casing is relatively cost-effective because of its simple structure and relatively low construction and maintenance costs. Slotted casing is an economical choice for some common wellbore completion projects or where excessive fine filtration is not required.

Screen Casing is relatively less cost-effective because it requires the use of more corrosion-resistant materials or coatings and a finer filter structure, resulting in higher costs. However, for environmental engineering or water resources management projects that require higher filtration accuracy, screen tube sleeves are an indispensable choice.

Overall, there are obvious differences between Slotted Casing and Screen Casing in terms of function, design and application, anti-corrosion level, and cost-effectiveness. According to the specific engineering needs and usage scenarios, choosing the appropriate casing structure is the key to ensuring the smooth progress of the project and effective utilization of resources.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :