Swivel Flange: Features, Applications and Advantages

Swivel Flange is a pipe connection component with special functions and is widely used in many industries. Due to its unique rotating design, the swivel flange can not only realize the flexible connection of the pipeline, but also maintain efficient and stable operation under high pressure and complex working conditions. This article will explore the role, material selection, application scenarios and comparison with other types of flanges of the swivel flange in depth to help industry insiders better understand and select swivel flanges.

Swivel flanges are typically made according to ASME B16.5, API 6A, and MSS SP44 standards. They are available in a wide range of swivel flanges dimensions, ensuring compatibility with various pipe sizes, from ½ inch to 60 inches, and pressure classes from 150 to 2500.

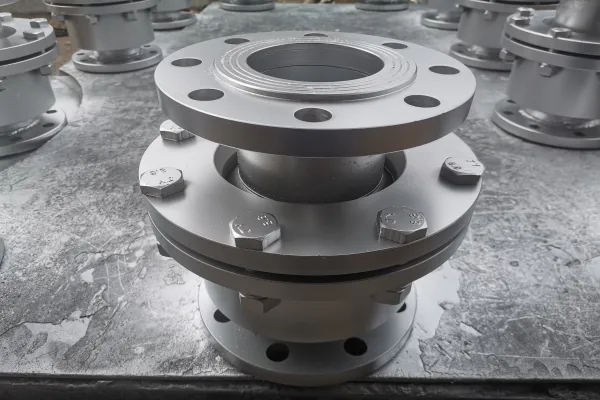

1. Definition and basic functions of swivel flange

Swivel flange is a connector consisting of a flange plate and a swivel joint. Its unique design allows the two connecting parts to rotate 360° under the action of the swivel joint, so that the angle between the pipeline or equipment can be adjusted. This adjustable function makes the swivel flange particularly suitable for industrial applications that require flexible installation and adjustment of the pipeline position. The swivel flange is usually connected to the pipeline or equipment by bolting or welding. While bearing internal and external pressure and gravity, it can also withstand large torque during operation.

The specifications and gaskets of swivel flanges usually comply with ASME B16.5, API 6A and MSS SP44 standards, and provide different pressure levels from Class 150 to Class 2500, suitable for 1/2 inch to 60 inch pipeline systems.

2. The main functions of swivel flanges

The design of swivel flanges not only enhances the stability of pipeline connections, but also provides other key functions, including:

Pipeline connection and disassembly

Swivel flanges can achieve quick connection and disassembly of pipelines, especially when regular maintenance or replacement is required, which can greatly improve the efficiency of disassembly and assembly. Bolt connection makes the installation process convenient, while the rotation function makes the connection between pipelines and equipment more flexible and reduces alignment errors.

Load-bearing function

The swivel flange itself has a strong load-bearing capacity and can work normally under high pressure and heavy load conditions. The swivel flange installed on the equipment or pipeline is connected to another equipment or pipeline through its swivel joint, bearing internal and external pressures and equipment gravity to ensure the stability of the system.

Angle adjustment and rotation function

The rotating flange can provide a 360° rotation angle, so that the pipeline or equipment can adjust its position or angle according to the process requirements. This is particularly important in some occasions where the direction of the pipeline needs to be adjusted, such as offshore oil platforms, complex chemical production lines, etc.

3. Application fields of rotating flanges

The rotating flange has been widely used in many industries due to its unique flexibility and load-bearing capacity:

Oil and gas industry

The oil and gas industry requires a large number of pipelines and equipment connections. The rotating flange can help engineers easily complete equipment installation and maintenance in a high-pressure environment. Its rotation characteristics are particularly suitable for complex oil and gas pipeline systems, which can improve construction efficiency and work safety.

Chemical industry

In chemical production, equipment and pipelines often need to be frequently cleaned or replaced. The quick connection and disassembly characteristics of the rotating flange allow the equipment to be quickly removed and reinstalled, thereby reducing downtime and improving the efficiency of the production line.

Food processing industry

Equipment in the food processing industry requires strict hygiene standards. The rotating flange can help the equipment to be quickly disassembled and reinstalled between different process sections, reduce food hygiene and safety risks, and improve the flexibility of the production process.

4. Marine Engineering and Shipbuilding

Swivel flanges are widely used in marine engineering and shipbuilding industries, especially in high pressure and deep sea environments. Their unique rotation ability and corrosion resistance make them an ideal choice. Swivel flanges can be used for pipeline connections of offshore oil and gas platforms, offshore drilling equipment, etc.

4. Material selection of swivel flanges

The material selection of swivel flanges is crucial, which directly affects the pressure resistance, corrosion resistance and service life of the flanges. Common swivel flange materials include:

Stainless steel (ASTM A182 F

304/304L/316/316L/321/347): suitable for highly corrosive environments such as chemical industry and marine engineering.

Duplex stainless steel (F51/F53/F44/F55/F60/F61): used in situations with higher requirements for corrosion resistance and strength.

Carbon steel (ASTM A105, API 6A AISI 4130): suitable for general industrial use and has good cost performance.

Alloy steel (ASTM A694 F52, F60, F65, F70): Excellent performance in high temperature and high pressure environments, suitable for deep well drilling and oil and gas transportation systems.

Swivel flanges can also be treated with PTFE coating, surfacing and other surface treatments as needed to enhance their corrosion resistance and extend their service life.

5. Comparison of Swivel Flanges with Other Flanges

Swivel flanges have unique advantages over other common flange types:

Welded flanges provide a more stable connection, but cannot adjust the angle of the pipe, which is not ideal for some applications that require flexible docking. Swivel flanges have adjustable functions to meet different installation and adjustment requirements.

Swivel flange vs. Sliding flange

Sliding flanges are easy to install, but their load-bearing capacity is not as good as that of swivel flanges. In harsh environments such as high pressure and high temperature, the strength and stability of swivel flanges are more advantageous.

Blind flanges are used to close the end of the pipe, while swivel flanges are used to connect and adjust the docking angle between pipes or equipment. The swivel flange can not only provide pipeline connection, but also be flexibly adjusted to meet complex process requirements.

6.Summary of the advantages of swivel flange

Due to its unique design and multiple advantages, the swivel flange is widely used in various industrial occasions, especially in high pressure, high temperature and complex environments. Its main advantages include:

Easy installation: The swivel flange can easily achieve quick connection and disassembly, reducing construction time and alignment errors.

High load capacity: Adapt to high pressure and heavy load conditions to ensure system stability.

Flexible and adjustable: The rotation function allows the angle between the pipeline and the equipment to be flexibly adjusted to meet the changing process requirements.

Widely used: It has important applications in industries such as petroleum, natural gas, chemical industry, and food processing.

Customized material selection: Different materials can be selected according to the working environment, and special surface treatment can be performed to enhance corrosion resistance and wear resistance.

Conclusion

As an efficient and flexible pipeline connection solution, the

swivel flange is widely used in many fields such as petroleum, natural gas, and chemical industry. Its rotation characteristics, load capacity and adaptability make it an indispensable connection component under high pressure, high temperature and complex working conditions. For applications that require frequent disassembly and adjustment of pipe angles, swivel flanges are undoubtedly the most suitable choice. When purchasing swivel flanges, it is recommended to comprehensively consider factors such as the working environment, pipe pressure, and corrosion resistance requirements to ensure that the most suitable product is selected.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :