Definition of blind flange

Blind flange is also called blind flange, and its real name is blind plate. Blind flange is a solid disc used to close a pipe or form a stopper. Similar to ordinary flanges, blind flanges have mounting holes around the periphery and gasket seals are machined on the mating surface. The difference is that the blind flange does not have an opening for fluid to pass through. Instead, it is placed between two open flanges, thereby blocking the fluid from passing through the pipe. This type of closure is often used when adding another pipeline to an existing pipeline or adding a new valve. One of its functions is to block the end of the pipe, and the second is to facilitate the removal of debris in the pipe during maintenance. In terms of the blocking effect, it has the same effect as the head and pipe cap. However, there is no way to disassemble the head, while the blind flange is fixed with bolts and is very convenient to disassemble. The materials of the blind flange are carbon steel, alloy steel, stainless steel, plastic, etc. The blind flange is used to seal the end of the pipeline. There are welded blind flanges and flange covers (flange covers are bolted). Flange covers are blind flanges, and blind flanges are not only flange covers, but also welded blind flanges, butt-wound blind flanges, etc. Where are blind flanges most commonly used? Blind flanges are commonly used in petrochemicals, pipeline engineering, utilities, and water conservancy projects. Blind flanges can be used to repair pipelines upstream. In fact, during pipeline construction, blind flanges can be embedded into the final length of the pipeline. In this way, the pipeline can be extended or continued by simply adding to the final flange. How are blind flanges designed? In the design of blind flanges, there are several key points that we need to pay attention to during design: to design the flange reasonably, that is, to properly design the ratio of the cone neck and flange ring of the alloy flange, so that the flange torque is as small as possible to reduce the various stress indicators of the flange; according to the use conditions, the gasket material and the gasket width are reasonably selected to reduce the preload and operating force of the bolts; the bolt material, bolt diameter and number of bolts are reasonably selected, and the value of the bolt center circle diameter is as small as possible; the flange material is reasonably selected, and the overall design of the flange should be as full stress design as possible to achieve the purpose of both safety and cost saving.

What does the blind flange do?

Without the blind flange, it would be almost impossible to repair or maintain the pipeline unless the flow was closed at the early valve, which could affect miles of pipelines.

The use of flanged pipes has greatly accelerated the construction process of pipelines. It also makes maintenance and pipe section replacement easier. Pipe sections can now be assembled anywhere in the world and then transported to the construction site. Once on site, they only need to be bolted in place and the repair is complete.

Where are Blind Flanges Most Commonly Used?

Blind flanges are commonly used in petrochemical, pipe engineering, public services and water works.

A blind flange is useful for making repairs to a pipeline further up the line. In fact, during construction of a pipeline, a blind flange may be built into the final length of pipe. This allows for expansion or continuation of the pipeline simply by adding onto the final flange.

Pipeline Termination:

Blind flanges are used to cap the end of a pipeline during construction or maintenance.

Access Points for Maintenance:

By sealing off sections of a pipeline, blind flanges provide a removable barrier that allows for inspection, cleaning, and repair.

Pressure Testing:

During hydrostatic or pressure testing, blind flanges ensure a sealed environment to evaluate the integrity of the pipeline or vessel.

Temporary Closures:

In systems where future expansion is anticipated, blind flanges are used to temporarily close off the pipeline.

Key Features of Blind Flanges

1.Solid Construction:

Blind flanges are manufactured as solid plates, designed to withstand high pressure and prevent any leakage.

2.Material Compatibility:

Blind flanges are available in a variety of materials, including:

Carbon steel

Stainless steel

Alloy steel

Nickel alloys

The choice of material depends on the operating environment and fluid type.

3.Design Options:

They can be flat-faced (FF), raised-faced (RF), or ring-type joint (RTJ) to suit various sealing requirements.

4.Pressure Ratings:

Blind flanges are available in multiple pressure classes, such as 150, 300, 600, 900, 1500, and 2500 pounds, to match the specifications of the piping system.

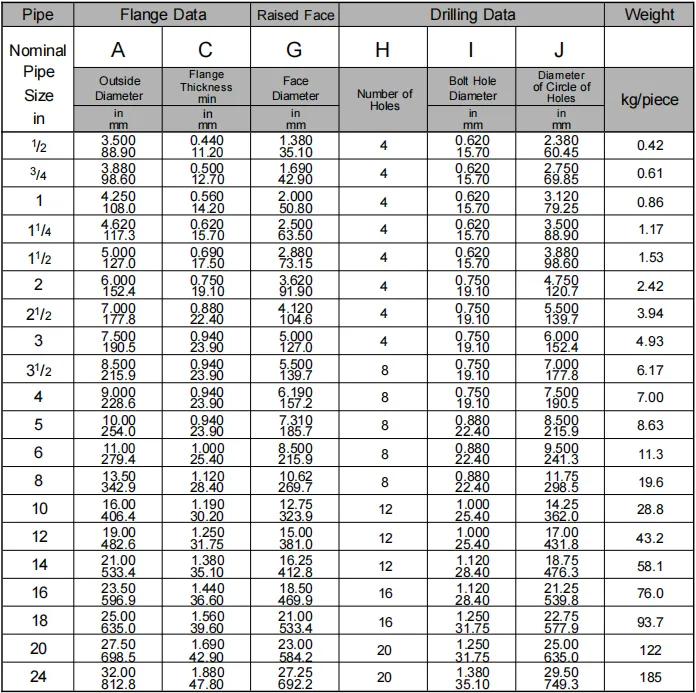

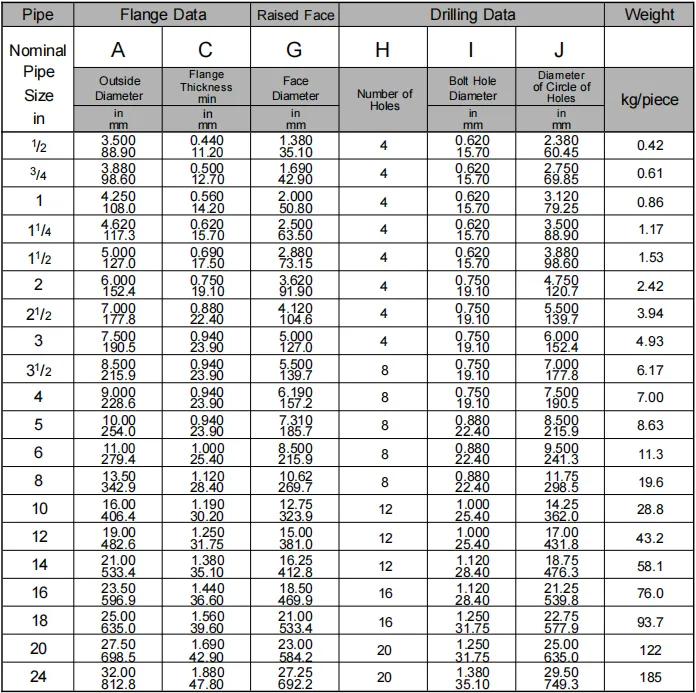

Blind flange dimensions class 150 (ASME B16.5)

BAOWI STEEL can match the material of the flange with a simple bolt kit. Each kit contains fasteners, nuts, washers and lock washers made of the same material as the flange and blind flange fitting. If you have questions about the best option for your application, please contact our experts.

what is Black steel blind flanges?

Black steel blind flanges are a type of flange made from uncoated or black-finished carbon steel, used to seal the ends of pipelines or pressure vessels. The term "black steel" refers to the surface appearance of the material, which is dark due to the mill scale left from manufacturing. These flanges are highly durable and cost-effective, making them a popular choice in various industries.

Galvanized blind flanges

Galvanized blind flanges are specialized components used in piping systems to terminate or seal off the ends of pipelines or pressure vessels. These flanges undergo a galvanization process, typically hot-dip or electro-galvanization, which coats the steel surface with a layer of zinc. The zinc coating provides superior corrosion resistance, making galvanized blind flanges ideal for outdoor or corrosive environments.

How to Choose the Right Blind Flange

Material:

Select a material compatible with the fluid, pressure, and temperature of the system.

Pressure Rating:

Ensure the pressure class of the blind flange matches the requirements of the pipeline or system.

Dimensions:

Verify that the dimensions, such as outer diameter, bolt circle diameter, and thickness, conform to industry standards like

ASME, ANSI, or API.

Surface Finish:

The sealing surface should have an appropriate finish to ensure proper gasket sealing and prevent leaks.

Conclusion

Blind flanges are indispensable components in piping systems, offering a reliable way to terminate or seal pipelines. Their solid construction, compatibility with various materials, and adaptability to different pressure classes make them a preferred choice across industries. Whether used for temporary closures, maintenance, or pressure testing, blind flanges provide safety, durability, and efficiency in demanding applications.

For any piping project, selecting the correct blind flange ensures optimal performance and long-term reliability.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :