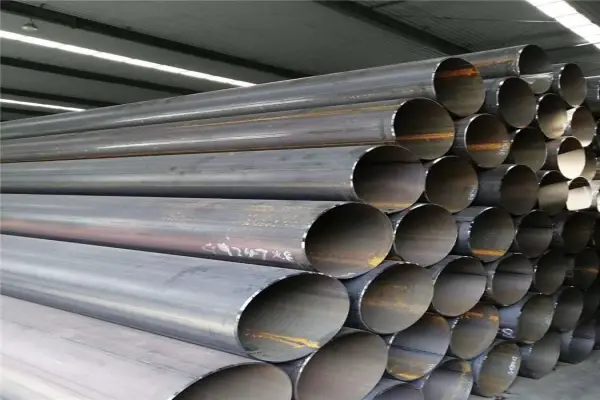

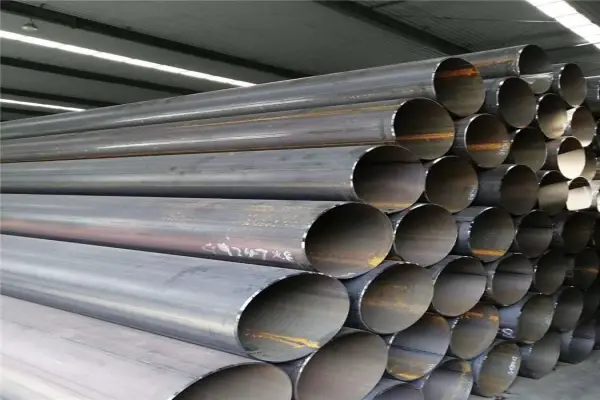

ASTM A795 ERW Pipe: The Ideal Solution for Fire Protection Systems

When it comes to modern fire protection systems, safety and reliability are paramount. Among the various options available, ASTM A795 ERW pipes stand out for their exceptional quality and versatility. Manufactured under rigorous international standards, these pipes provide superior performance in diverse fire safety applications.

What is ASTM A795 ERW Pipe?

ASTM A795 ERW pipes are produced according to the ASTM A795 standard, which governs black and hot-dipped galvanized steel pipes, both welded and seamless. Specifically designed for fire protection systems, these pipes are built to endure demanding environments while ensuring reliability.

The term ERW refers to "Electric Resistance Welding," a process that fuses the edges of steel using heat generated by electrical resistance. This method creates a strong, durable weld.

Key Features of ASTM A795 ERW Pipe

Heat and Pressure Resistance

These pipes withstand extreme temperatures and high pressures, maintaining their integrity in critical situations.

Corrosion Resistance

Galvanized coatings provide excellent protection against rust, extending the lifespan of the pipes even in humid or aggressive environments.

Versatile Applications

Available in a wide range of sizes, wall thicknesses, and finishes, these pipes can meet various project requirements.

Common Applications of A795 ERW Pipe

ASTM A795 ERW pipes are widely used in fire protection systems, including:

Automatic sprinkler systems, both wet and dry.

Fire water supply networks for indoor and outdoor use.

Fire hydrants and deluge systems.

Their adaptability makes them suitable for various configurations and setups in fire safety.

Surface treatments for ASTM A795 ERW pipe

Surface treatment plays a vital role in enhancing the performance and lifespan of ASTM A795 ERW pipes. Some popular options include:

Hot-Dip Galvanizing

Hot-dip galvanizing melts zinc ingots at high temperatures, puts in some auxiliary materials, and then immerses metal structural parts in a galvanizing bath to attach a layer of zinc to the metal components. Hot dip galvanizing is an effective method of corrosion protection for A795 ERW pipe

Crafting process

Workpiece → degreasing → water washing → pickling → water washing → dipping in plating solvent → drying and preheating → hot dip galvanizing → finishing → cooling → passivation → rinsing → drying → inspection.

Electro-galvanized

The purpose of electro-galvanizing is to prevent steel objects from being corroded, improve the corrosion resistance and service life of steel, and also add a decorative appearance to the product. In order to protect the service life of steel pipes or their parts, electro-galvanizing is generally used to Processing. Electrogalvanizing is the most common coating used for commercial fasteners. It is cheaper and has a better appearance. It can be available in blue and white, silver, black, and military green.

Black or Red PaintPowder coating

This method involves applying a dry powder coating to the pipe's surface, followed by curing under heat. Black powder-coated steel pipes are common.

Key Specifications Painting

ASTM A795 ERW steel pipes usually need to be painted when used as fire pipes. As a special water supply network, fire protection pipelines have strict requirements and regulations for pipelines, including anti-corrosion performance and meeting certain pressure standards. Therefore, it is necessary to paint the pipes, which not only helps to provide additional corrosion protection, but also makes the pipes easily identifiable among many pipelines. In practical applications, fire pipes are usually painted in eye-catching red. The purpose of this is to quickly identify fire pipes in an emergency and ensure the efficient operation of the fire protection system.

End Finishes:

Plain or square cut.

Beveled to 30°.

Grooved as per AWWA C606.

NPT or BSPT threads as required.

These specifications ensure seamless integration into various fire protection systems.

Manufacturing Process of ASTM A795 ERW Pipe

The production process ensures high precision and consistent quality. The steel is rolled into strips, and the edges are welded using electric resistance. The weld seam undergoes heat treatment to eliminate imperfections and ensure optimal strength.

For galvanized pipes, the process involves multiple steps, including degreasing, pickling, drying, preheating, and immersion in molten zinc. This creates a robust protective layer that enhances corrosion resistance.

The ERW process ensures a consistent and robust weld seam. Key steps include:

Forming: Steel coils are unrolled and shaped into cylindrical forms.

Welding: Edges are welded together using high-frequency electric resistance.

Sizing and Straightening: Pipes are calibrated to precise dimensions and checked for straightness.

Testing and Inspection: Pipes undergo hydrostatic testing and nondestructive inspections to ensure compliance with ASTM A795 standards.

Conclusion

ASTM A795

ERW pipes deliver exceptional performance and reliability in fire protection systems. From their resistance to extreme conditions to their customizable specifications, these pipes are designed to meet the highest standards of safety and efficiency.

If you’re planning a fire protection project, ASTM A795 ERW pipes are a smart and dependable investment. Their proven quality ensures that your system remains secure for years to come.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :