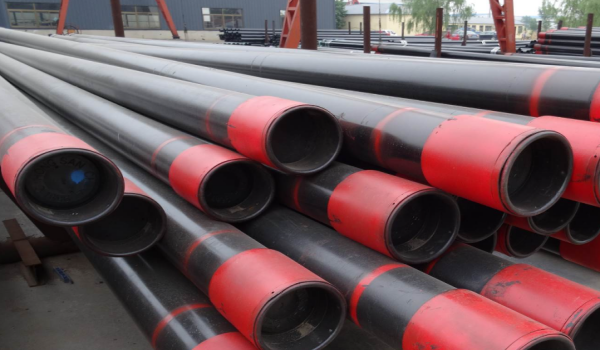

API 5CT P110 Casing Pipe: Specifications, Features, and Applications

The API 5CT P110 casing pipe is a crucial component in the oil and gas industry, designed to handle the demanding environments of deep-well drilling. With its superior mechanical properties, precise manufacturing standards, and compliance with API 5CT specifications, P110 casing is an industry favorite for high-performance applications.

API 5CT P110 Casing Pipe Meaning

API 5CT is a specification established by the American Petroleum Institute (API) for casing and tubing used in the oil and gas industry. Casing pipes are essential components used to line the walls of drilled oil and gas wells, providing structural integrity and preventing the wellbore from collapsing.

The term P110 refers to a specific grade of casing pipe within the API 5CT standard. Here's a breakdown of its meaning:

P: Indicates the grade of the casing, specifying the mechanical properties such as yield strength, tensile strength, and hardness.

110: Represents the minimum yield strength of the material, measured in ksi (thousand pounds per square inch). For P110 casing, the yield strength is at least 110 ksi (758 MPa).

Specifications of API 5CT P110 Casing Pipe

Outer Dimensions: 6.0mm to 219.0mm

Wall Thickness: 1.0mm to 30.0mm

Length Options:

R1: 4.88m to 7.62m

R2: 7.62m to 10.36m

R3: 10.36m to 14.63m

Thread Types:

Short Round Thread (STC)

Long Round Thread (LTC)

Buttress Thread (BTC)

Material Types:

API 5CT N80 Type 1

API 5CT N80 Type Q

API 5CT P110 Casing Pipe Size Chart

|

Outer Diameter

|

Wall Thickness

|

Weight

|

Grade

|

Threaded

|

Length

|

|

in

|

mm

|

kg/m

|

lb/ft

|

|

4 1/2″

|

114.3

|

14.14-22.47

|

9.50-11.50

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

5″

|

127

|

17.11-35.86

|

11.50-24.10

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

5 1/2″

|

139.7

|

20.83-34.23

|

14.00-23.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

6 5/8″

|

168.28

|

29.76-35.72

|

20.00-24.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

7″

|

177.8

|

25.30-56.55

|

17.00-38.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

7 5/8″

|

193.68

|

35.72-63.69

|

24.00-42.80

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

8 5/8″

|

219.08

|

35.72-72.92

|

24.00-49.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

9 5/8″

|

244.48

|

48.07-86.91

|

32.30-58.40

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

10 3/4″

|

273.05

|

48.73-97.77

|

32.75-65.70

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

11 3/4″

|

298.45

|

62.50-89.29

|

42.00-60.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

|

13 3/8″

|

339.72

|

71.43-107.15

|

48.00-72.00

|

P110

|

LTC/STC/BTC

|

R1/R2/R3

|

Key Features of API 5CT P110 Casing Pipe

1. Superior Mechanical Properties

The P110 grade offers higher tensile and yield strength than many other casing pipe grades. This makes it suitable for deep-well applications where extreme pressures and temperatures are common.

2. Deep-Well Capability

P110 casing is typically used in wells that extend deeper than most, providing reliable performance in challenging terrains and complex drilling environments.

3. Versatile End Connections

The casing comes with various thread options, including short round threads, long round threads, and buttress threads, ensuring compatibility with a wide range of drilling setups.

4. Strict Compliance with API Standards

API 5CT P110 casing adheres to rigorous quality controls and inspection protocols, meeting the highest industry standards for reliability and safety.

Applications of API 5CT P110 Casing Pipe

Casing Pipe in Oil and Gas Drilling

P110 casing is commonly used in the transportation of oil, natural gas, and water in deep wells.

It serves as a structural component to maintain well integrity.

High-Pressure Environments

Ideal for deep wells requiring pipes with high tensile and yield strength.

Complex Geological Conditions

Effective in wells with difficult formations and high operational stresses.

Inspection and Quality Assurance

To ensure reliability and performance, API 5CT P110 casing pipes undergo comprehensive testing and inspection.

Inspection Parameters

Hydrostatic Testing: Verifies pressure resistance at up to 3,000 psi.

Dimensional Accuracy: Ensures uniformity in outer diameter, wall thickness, and length.

Weight and Straightness: Confirms proper distribution and alignment.

Drift Testing: Ensures the clearance required for downhole tools.

Testing Methods

Non-Destructive Testing (NDT): Includes electromagnetic, magnetic particle, and ultrasonic testing for detecting surface and internal flaws.

Chemical and Physical Analysis: Verifies material composition and mechanical properties.

Third-Party Certification: Guarantees adherence to

API 5CT standards.

Where to Buy API 5CT P110 Casing Pipe?

Leading casing pipe manufacturers and suppliers, such as

Baowi Steel, We provide high-quality API 5CT P110 casing pipes, along with complementary products like casing couplings, perforated pipes, and

pup joints. These companies ensure reliable delivery and support, catering to the demanding requirements of the oil and gas industry.

Conclusion

The API 5CT P110

casing pipe is a cornerstone of the oil and gas industry, renowned for its strength, reliability, and versatility in deep-well applications. Its superior mechanical properties, coupled with stringent quality standards, make it an indispensable tool for operators facing complex drilling challenges. Whether you need a solution for high-pressure environments or deep drilling projects, P110 casing pipe provides the performance and dependability required to succeed.For professionals seeking the best in oilfield equipment, investing in API 5CT P110 casing pipes ensures both efficiency and peace of mind in critical operations.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :