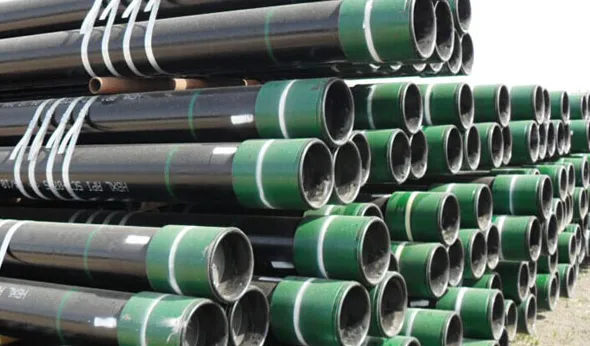

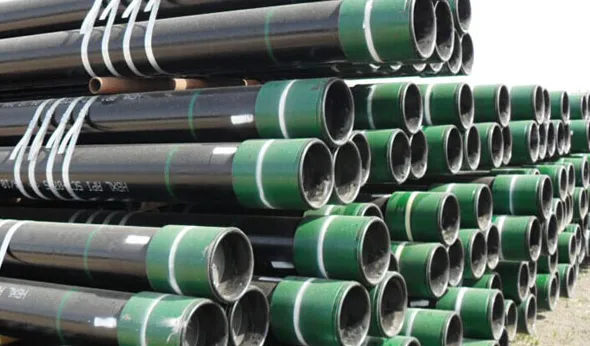

Petroleum and combustible gases (such as natural gas, shale gas, and coalbed methane) are the primary energy sources consumed by humans today. In recent years, the global consumption of fossil fuels has continued to grow, leading to an increased demand for corresponding equipment, such as tubing and casing, well pipe casing, drill pipes, drill collars, etc. In the process of oil and gas exploration and development, well pipe casing is an essential material and equipment, accounting for 20% to 30% of the total well construction cost. The steel grades of oil well pipe casing include H40, J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Today, we will focus on the K55 grade well pipe casing.

What is K55?

K55 refers to the steel grade used for oil well pipe casing. Different steel grades determine the physical properties of the pipe body, mainly including compressive and torsional strength. K55 grade oil well pipe casing has a yield strength range of 379-552 MPa and a tensile strength greater than 655 MPa, with a yield ratio between 0.58 and 0.84. This means that K55 has a lower yield ratio, allowing it to maintain good plasticity and toughness under high-stress environments.

Applications Suitable for K55 Grade Well Pipe Casing

Oil and Gas Exploration

K55 grade well pipe casing is primarily used in oil and gas exploration and development. Its high strength and low yield ratio enable it to provide reliable support in complex underground environments, preventing wellbore collapse and ensuring the safe operation of oil and gas wells.

High-Pressure Environments

Due to its high tensile and compressive strength, K55 grade is very suitable for well pipe casing in high-pressure environments. In these environments, the well pipe casing needs to withstand enormous pressure and stress, and the excellent performance of K55 grade ensures its long-term stable operation.

Characteristics of API 5CT K55 Well Pipe Casing

Structural Integrity

K55 well pipe casing is placed underground to ensure the structural integrity of the wellbore. It must withstand external collapse pressure from rock formations and internal yield pressure from fluids and gases. During operation, it must also bear its own load and withstand applied torque and axial pressure.

Corrosion Resistance

API 5CT K55 well pipe casing is coated with a protective layer on the outer surface to enhance its corrosion resistance. This protective layer effectively prevents corrosion from the underground environment, extending its service life.

API 5CT K55 Tubing

K55 tubing is placed inside the casing to transport oil and gas from the reservoir to the wellhead. API 5CT K55 oilfield casing is very similar to J55 in terms of chemical composition and yield strength, but K55 has a higher ultimate tensile strength, with K55/J55 being 655 MPa and 517 MPa, respectively.

Superior Mechanical Properties

K55 has better mechanical and thermal fatigue properties and crack resistance compared to J55. For thermal recovery wells, it is suitable to use K55 thick-walled casing instead of J55 casing, as the former has better thermal fatigue resistance.

Application Scenarios

In oil drilling, K55 API 5CT casing or tubing is a common type. They are widely used in non-corrosive well installations where high strength is not required. K55 casing is typically used during the drilling process to provide necessary support and protection.

Comparison Between K55 and Other Steel Grades

Differences Between J55 and K55

In the API 5CT standard, J55 and K55 casing and tubing are lower-grade material pipes. They have the same chemical composition and yield strength (379-552 MPa) but different tensile strengths, with J55 being the lowest at 517 MPa and K55 at 655 MPa. Although there are some differences in performance, their sales prices are generally consistent in the market, and their applications are very similar.

N80, L80, P110, and Other Steel Grades

In comparison, the K55 grade is lower than N80, L80, P110, or T95, making it a cheaper material option widely used in non-corrosive well installations where high strength is not required. N80, L80, P110, and other grades are suitable for more complex environments and higher pressure requirements.

Manufacturing and Inspection of K55 Well Pipe Casing

Manufacturing Process

The manufacturing process of K55 well pipe casing includes multiple steps such as hot rolling, cold drawing, and heat treatment. Each step is strictly carried out according to the API 5CT standard to ensure the quality and performance of the casing.

Quality Inspection

After manufacturing, K55 well pipe casing undergoes a series of strict quality inspections, including chemical composition analysis, mechanical performance testing, dimensional inspection, and non-destructive testing. Only products that meet the API 5CT standard can be shipped.

Conclusion

K55 grade well pipe casing plays a crucial role in oil and gas exploration and development. Its high strength, low yield ratio, and excellent tensile and compressive properties enable it to provide reliable support in complex underground environments, preventing wellbore collapse and ensuring the safe operation of oil and gas wells. Although there are some differences in performance between K55 and J55, their market prices and application scenarios are similar. Overall, K55 well pipe casing is a cost-effective choice widely used in non-corrosive well installations and applications.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :