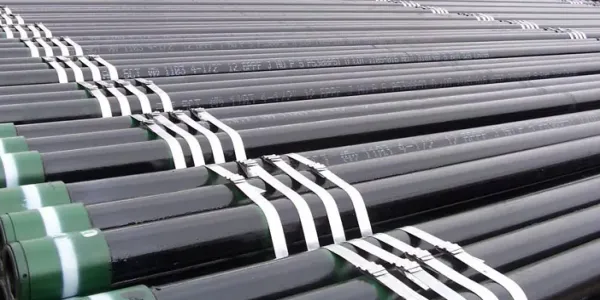

In the exploration of oil and gas, OCTG

casing pipes are used to support the well walls of oil and gas wells. They are essential for ensuring the drilling process and the normal operation of the entire well after completion. Thus, the use of OCTG casing pipes is critically important. OCTG (Oil Country Tubular Goods) refers to a series of pipes used in oil and gas drilling and production, including tubing, casing, and

drill pipes.

API 5CT is a standard set by the American Petroleum Institute (API) to regulate the technical requirements and specifications for casing and tubing used in the oil and gas industry.

Design Features and Advantages of OCTG Casing Pipes

1. High Strength

In oil exploration and extraction, wells are often very deep, requiring the casing to withstand high pressures and loads. The use of high-strength materials is crucial. OCTG casing pipes have undergone extensive research and optimization in material selection and manufacturing processes to ensure sufficient strength and hardness to withstand high pressures and heavy loads. This high strength makes OCTG casing pipes ideal for deep well drilling operations.

2. Corrosion Resistance

During oil extraction, the downhole environment is complex, with various corrosive factors such as high temperatures, high pressures, gases, water, and acids. This demands high corrosion resistance for the casing pipes. Manufacturers improve the corrosion resistance of OCTG casing pipes by using corrosion-resistant materials and surface anti-corrosion coatings, ensuring long-term stable use in harsh environments. This corrosion resistance gives OCTG casing pipes a significant advantage in highly corrosive environments.

3. Excellent Sealing

The sealing performance of OCTG casing pipes is a key factor in preventing leaks in oil wells. Manufacturers use high-quality sealing materials and advanced manufacturing processes to ensure the best sealing performance of the casing pipes, effectively preventing oil well leakage. This not only ensures production safety but also reduces environmental pollution risks.

4. Easy Maintenance and Replacement

The design of OCTG casing pipes facilitates easy installation, removal, and replacement. The pipes are designed to be detachable and movable, allowing maintenance personnel to quickly replace or handle issues when they arise. This ease of maintenance enhances the efficiency of using the casing pipes, ensuring the normal and stable production of oil.

Application of API 5CT Standard

API 5CT is a crucial standard that regulates the technical requirements and specifications for casing and tubing in the oil and gas industry. OCTG casing pipes manufactured according to API 5CT standard have the following advantages:

1. High Standard Material Selection

API 5CT standard specifies the material composition and mechanical properties of casing and tubing, ensuring sufficient strength, toughness, and corrosion resistance. Common steel grades include J55, K55, N80, L80, C90, T95, P110, Q125, and V150. Different steel grades are suitable for various well conditions and operational environments, ensuring safe and efficient operations under complex conditions.

2. Standardized Production Process

API 5CT standard details the production process, including heat treatment, welding, and non-destructive testing. Strict control of the production process ensures consistency and reliability in the quality of the casing pipes. Additionally, the API 5CT standard specifies detailed dimensions for the outer diameter, wall thickness, and length of the casing pipes, ensuring interchangeability and compatibility during installation and use.

3. Comprehensive Testing and Quality Control

API 5CT standard requires rigorous quality testing for casing pipes, including mechanical performance tests, pressure tests, and corrosion resistance tests. These testing methods ensure that each casing pipe meets design and use standards before leaving the factory. Furthermore, the API 5CT standard specifies marking and traceability systems for the casing pipes, ensuring quick location and handling of issues when they occur.

Classification and Application of OCTG Casing Pipes

In the extraction of oil and gas, OCTG casing pipes are classified into four main types based on different operational needs: conductor casing, surface casing, intermediate casing, and production casing. Each type of casing pipe has its unique functions and application scenarios.

1. Conductor Casing

Conductor casing is mainly used in offshore and desert drilling to isolate seawater and sand, ensuring smooth drilling. The primary specification for conductor casing is 762mm (30 inches), designed to provide initial wellbore stability.

2. Surface Casing

Surface casing is used for the first drilling to penetrate soft surface layers to bedrock, sealing off collapsing formations and preventing contamination from shallow water and gas layers. Surface casing specifications include 508mm (20 inches), 406.4mm (16 inches), and 339.7mm (13-3/8 inches). The installation depth for surface casing typically ranges from 80 to 1500 meters.

3. Intermediate Casing

Intermediate casing is used during drilling through complex formations. When encountering collapsible layers, oil layers, gas layers, water layers, or lost circulation zones, intermediate casing is required for sealing. The main specifications for intermediate casing include 244.5mm (9-5/8 inches) and 177.8mm (7 inches). Depending on different well conditions and formation characteristics, steel grades for intermediate casing often include N80, L80, and P110.

4. Production Casing

Production casing is used to drill to the target formation and seal off all exposed formations above. The inside of the production casing contains the tubing. Production casing has the deepest setting depth among all casing types, with the highest requirements for mechanical performance and sealing. Common steel grades include K55, N80, P110, and Q125. The main specifications for production casing include 127mm (5 inches), 139.7mm (5-1/2 inches), and 168.3mm (6-5/8 inches).

Cost-Effectiveness of OCTG Casing Pipes

The design of OCTG casing pipes offers significant cost-effectiveness. First, the use of high-quality materials and advanced manufacturing processes extends the service life of the casing pipes, reducing frequent replacement and maintenance costs. Second, the ease of installation and removal of OCTG casing pipes reduces construction time and labor costs. Finally, the high strength and corrosion resistance of OCTG casing pipes improve the overall efficiency and safety of the well, reducing economic losses from equipment failures and environmental pollution.

Weight Calculation and Specifications

The weight calculation formula for oil casing pipes is:

Weight per meter=2×wall thickness×(outer diameter−wall thickness)×0.02466

For example, for N80 grade casing pipes, the outer diameter typically ranges from 127mm to 508mm. API specifies three lengths: R-1 (4.88 to 7.62 meters), R-2 (7.62 to 10.36 meters), and R-3 (10.36 meters and above). Different well conditions and depths require casing pipes of various steel grades. In corrosive environments, casing pipes need corrosion resistance, while in geologically complex areas, casing pipes must have crush resistance. The end processing forms of casing pipes include short round threads, long round threads, trapezoidal threads, and special threads.

Conclusion

The development of OCTG casing pipes and API 5CT casing pipes is unstoppable due to their advantages aligning with modern development needs. It is well known that using products requires not only convenience but also quality assurance. The continuous advancement of OCTG casing pipes in modern times makes their development trend unstoppable. We believe that with future technological advancements, OCTG casing pipes will possess even more advantages.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :