API (American Petroleum Institute) has published a series of standards for the oil and gas industry, including API 5B and API 5CT. These two standards are important standards specifically for casing and tubing, covering the specifications, materials, manufacturing methods, inspection and acceptance requirements of steel pipes. This article will introduce the content, steel grades, application scenarios and related technical details of API 5B and API 5CT in detail.

1.API 5B: Specification for Threads, Measurement and Thread Inspection of Casing and Tubing

The API 5B standard mainly deals with the threads, measurement and thread inspection of casing, tubing and pipeline threads. API 5B includes casing and couplings of J55, K55, N80 (Class 1, Q) and P110 steel grades, and specifies the size and marking requirements of their threads and thread gauges, thread measurement methods, thread gauge specifications and identification regulations, and instruments and methods for inspecting round thread casing and trapezoidal thread casing. API 5B applies to products produced according to API standards. The measurement methods of thread taper, pitch, thread height, thread angle and thread angle are applicable to threads with no more than 11.5 threads per inch. The listed thread sizes without deviation are only used as the basis for connection design and do not need to be measured to determine product acceptance or rejection.

API 5B main aspects:

Threaded component instrumentation: tools and instruments used to measure and inspect threads.

Instruments and wire pipe: equipment and methods used to produce and inspect threads.

Round thread casing: specifies the dimensions and inspection requirements for round thread casing pipe.

Thread inspection requirements for supporting casing pipe connections: ensure that the threads of casing pipe connections meet the specification requirements.

With the API 5B standard, manufacturers and users can ensure that the threaded connections of casing and tubing are consistent and reliable, meeting the stringent requirements of the oil and gas industry.

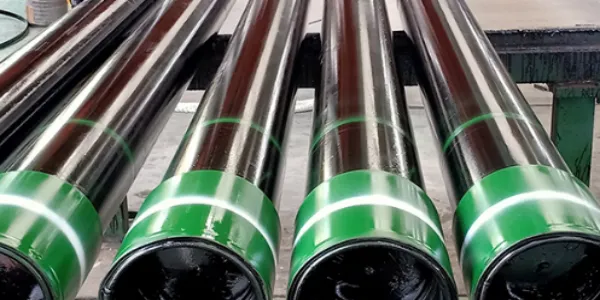

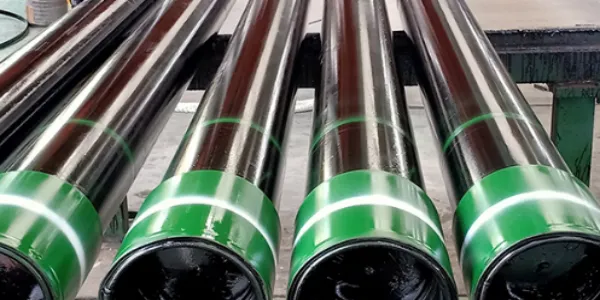

2.API 5CT: Specifications and technical delivery conditions for steel casing

The API 5CT standard applies to steel pipes for casing and tubing used in wells in the petroleum and natural gas industry. API 5CT specifies the technical delivery conditions for steel pipes (including casing, tubing and nipples), coupling stocks, coupling materials and accessory materials. API 5CT sets three product specification levels (PSL-1, PSL-2 and PSL-3), covering requirements from basic level to advanced level.

2.1Main aspects of API 5CT:

Specifications and materials of steel pipes: API 5CT covers a variety of steel grades, including H-40, J-55, K-55, N-80, L-80, C-90, T-95, P-110 and Q-125.

Technical delivery conditions: including chemical composition, mechanical properties, manufacturing methods and inspection requirements of steel pipes.

Product specification level (PSL): API 5CT defines three product specification levels, namely PSL-1 (basic level), PSL-2 (intermediate level) and PSL-3 (high level), each with different inspection and quality requirements.

2.2API 5CT steel classification and its application

API 5CT steel is divided into four main groups, each of which is suitable for different downhole conditions according to its yield strength, tensile strength and other characteristics:

Group 1: H-40, J-55, K-55, M-65, N-80, R-95

H-40, J-55, K-55: These steels have low strength and relatively low price, and are suitable for oil wells with low requirements for corrosion protection and strength.

M-65, N-80, R-95: These steels have high strength and are suitable for medium-depth oil and gas wells.

Group 2: C-90, L-80, T-95

C-90, L-80, T-95: These steels have good resistance to sulfide stress cracking (SCC) and are suitable for oil and gas wells in hydrogen sulfide (H2S) environments.

Group 3: P-110

P-110: This steel grade has high strength and is suitable for deep wells and high-pressure formations.

Group 4: Q-125

Q-125: This steel grade has the highest strength and is suitable for underground environments at extreme depths and high pressures.

3.Special requirements for API 5CT casing

The API 5CT standard requires additional testing of certain steel grades to ensure that they are suitable for the intended application scenarios. These tests include:

Sulfide stress cracking test: especially applicable to corrosion-resistant steel grades such as C-90, L-80 and T-95.

Slump test: applicable to casing that needs to be used in complex geological conditions to ensure that it has sufficient anti-slump ability.

Heat treatment: Depending on the different steel grades and application scenarios, the heat treatment methods of casing are different to adjust its mechanical properties.

Recommendations for the use of API 5CT casing pipe

According to factors such as well depth, formation pressure and corrosive environment, appropriate grades of casing should be selected:

Shallow wells and low-pressure wells: low-strength steels such as H-40, J-55 and K-55 can be selected.

Medium depth and medium pressure wells: medium-strength steels such as M-65, N-80 and R-95 are recommended.

High-pressure and deep wells: high-strength steels such as P-110 and Q-125 should be selected.

Corrosive environment: In corrosive environments containing hydrogen sulfide or carbon dioxide, corrosion-resistant steels such as L-80, C-90 and T-95 should be used.

The API 5D standard is governed by the API Tubular Products Standardization Committee and is intended to provide standards for drill pipes suitable for drilling and production operations. The API 5D standard includes two groups of drill pipes:

Group 1: E-grade drill pipe: Suitable for conventional drilling operations, with high toughness and fatigue resistance.

Group 3: High-strength drill pipe: Including X-95, G-105 and S-135 grades, suitable for deep well and high-pressure drilling operations.

The API 5D drill pipe standard ensures the quality and performance of drill pipes, enabling them to withstand harsh downhole conditions and provide reliable drilling services.

API 5L: Pipeline Specifications

The API 5L standard applies to pipelines that transport oil, natural gas, and other fluids. The standard covers the manufacturing, inspection, and acceptance requirements for pipelines, ensuring that the pipelines have sufficient strength and durability during long-distance transportation.

5.Conclusion

API 5B and API 5CT standards provide detailed casing and tubing specifications for the oil and gas industry. These standards cover the materials, manufacturing methods, inspection requirements, and application scenarios of steel pipes, ensuring the safety and reliability of downhole operations. By choosing the right steel grades and specifications, oil and gas companies can optimize their downhole operations, reduce costs, and improve efficiency.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :