Threaded pup joints are commonly used fittings for industrial pipe connections. Depending on the specific application, threaded pup joints can be divided into single-threaded pup joints and double-threaded pup joints. A single-threaded pup joint has external threads on one end, while a double-threaded pup joint has external threads on both ends. These joints serve the purpose of connecting, extending, and converting in various engineering projects. This article will provide a detailed introduction to the usage methods, standards, manufacturing materials, machining precision, load-bearing capacity, corrosion resistance, service life, threaded connection performance, testing methods, and marking, packaging, transportation, and storage of threaded pup joints.

Usage Methods and Applications of Threaded Pup Joints

Threaded pup joints are connected using a threaded connection method and are mainly suitable for imperial pipes, not for metric pipes. The production of threaded pipe fittings must comply with the American ANSI B16.11 and GB/T14626 standards. The common types of pipe threads used in engineering are as follows:

ISO7/1: This is an internationally accepted threaded sealing pipe thread with a thread angle of 55 degrees and a taper of 1:16. The internal thread can be either parallel (Rp) or tapered (Rc), while the external thread is only tapered (R). Among these, Rp-R connections are more commonly used in public engineering, while Rc-R connections are less common.

ISO228: This is an internationally accepted non-threaded sealing pipe thread with a thread angle of 55 degrees. Both internal and external threads are parallel.

ANSI B1.20.1: This is an American threaded sealing pipe thread with a thread angle of 60 degrees (NPT) and a taper of 1:16. Both internal and external threads are tapered and are commonly used in high-temperature and high-pressure pipelines. ANSI B16.11 threaded pipe fittings typically use NPT threads. Although the thread angles of NPT and ISO7/1 (BSP) are different, the thread pitch for 1/2 and 3/4 sizes is the same, allowing them to be connected interchangeably.

Types and Materials of Threaded Pipe Fittings

Threaded pipe fittings refer to fittings with threads and are commonly made of materials such as stainless steel, alloy steel, and carbon steel. These materials make threaded pipe fittings suitable for various pipe connections. Threaded pipe fittings can be subdivided into various types, including:

Threaded Elbows

Threaded Crosses

Threaded Tees

Threaded Couplings

Threaded Caps

Threaded Unions

Threaded Pup Joints

Reducing Pup Joints

Hexagonal Nipples

Threaded Plugs

Threaded Bushings

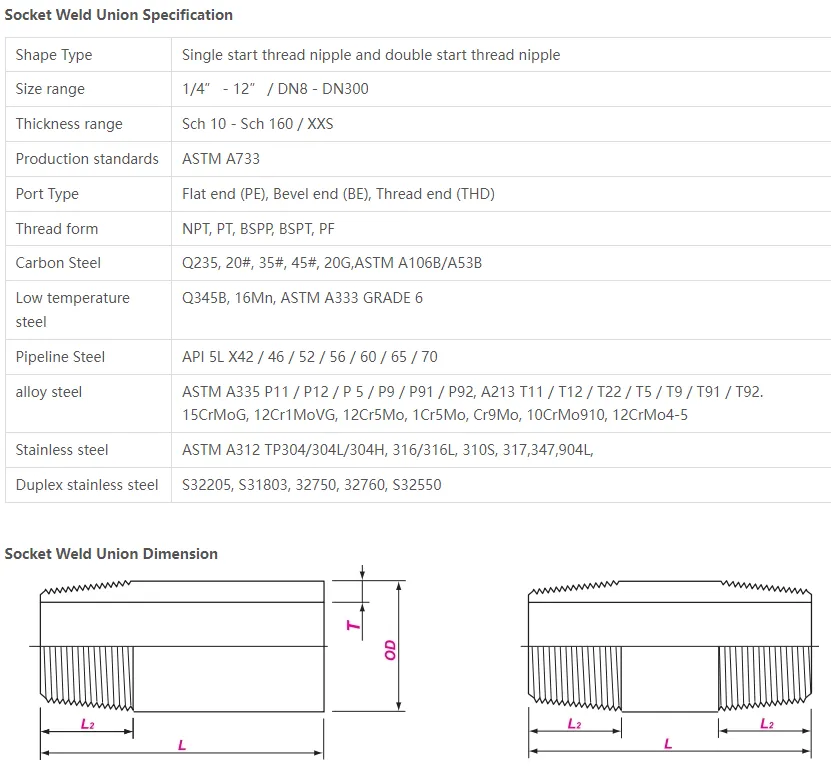

Standards for Single-Threaded Pup Joints

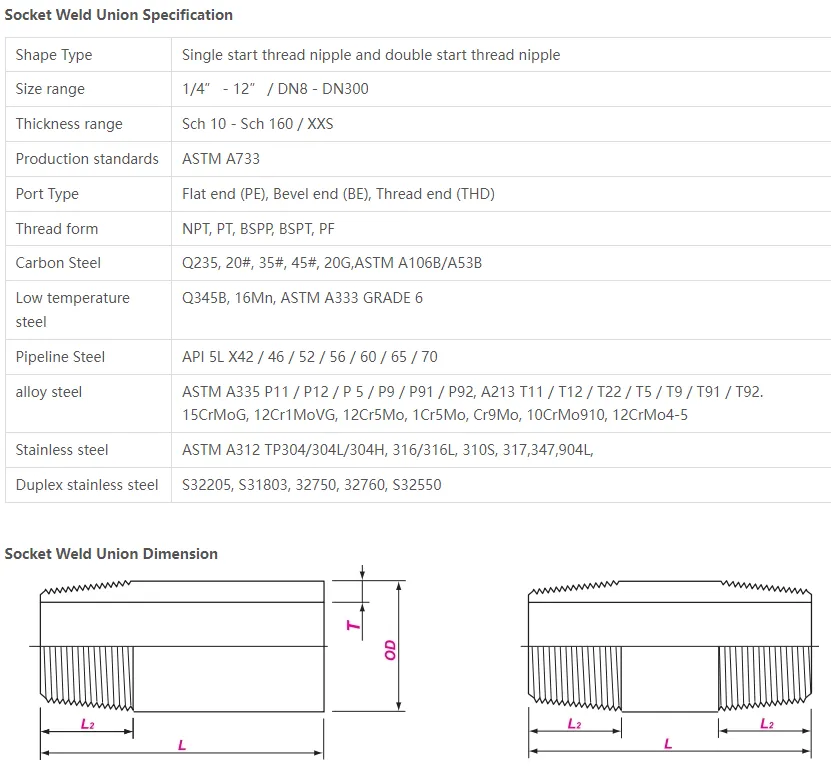

1. Dimensional Specifications

The standard dimensional specifications of single-threaded pup joints should comply with relevant regulations, including parameters such as the length, diameter, and pitch of the threaded portion. The allowable tolerances for these dimensions should be within the specified range to ensure connection performance and usage requirements.

2. Thread Forms

The thread forms of single-threaded pup joints should comply with the standards specified in GB/T196 and GB/T197 to ensure interchangeability and fastening reliability of the connections. Common thread forms include standard threads and fine threads.

3. Manufacturing Materials

The manufacturing materials of single-threaded pup joints should possess excellent mechanical properties and corrosion resistance to meet usage requirements. Common manufacturing materials include carbon steel and stainless steel.

4. Surface Treatment

The surface treatment of single-threaded pup joints should comply with relevant regulations to enhance their corrosion resistance and appearance. Common surface treatment methods include galvanizing and painting.

5.Machining Precision

The machining precision of single-threaded pup joints should comply with relevant regulations to ensure connection performance and usage requirements. Machining precision includes the accuracy requirements for parameters such as thread pitch, thread angle, and diameter of the threaded portion.

6.Load-Bearing Capacity

Single-threaded pup joints should have a certain load-bearing capacity to withstand the loads transmitted by the connected parts. The load-bearing capacity depends on factors such as the material, dimensions, and machining precision of the pup joints.

7.Corrosion Resistance

Single-threaded pup joints should have good corrosion resistance to suit different environmental usage requirements. The selection of manufacturing materials and the application of surface treatment methods will affect their corrosion resistance.

8.Service Life

The service life of single-threaded pup joints depends on factors such as materials, machining precision, and usage environment. Under normal conditions, single-threaded pup joints should maintain their connection performance and usage requirements for a certain service life.

9.Threaded Connection Performance

Single-threaded pup joints should have good threaded connection performance to ensure a tight fit and stable, reliable connection with the connected parts. Threaded connection performance includes aspects such as engagement, fastening, and durability.

10.Testing Methods

Conducting various performance tests on single-threaded pup joints is an important step in ensuring product quality. Testing methods should comply with relevant standards, including dimensional inspection, thread inspection, load-bearing capacity testing, and corrosion resistance testing.

11.Marking, Packaging, Transportation, and Storage

Single-threaded pup joints should be marked, packaged, transported, and stored in accordance with relevant regulations. Markings should be clear and include information such as product name, specification, model, and manufacturer. Packaging should be firm and reliable to prevent damage during transportation. During transportation, avoid severe vibrations and impacts, and ensure a dry and clean storage environment to prevent corrosion and contamination.

Conclusion

As essential fittings for industrial pipe connections, threaded pup joints are widely used in various engineering projects. By adhering to relevant standards and selecting appropriate manufacturing materials and surface treatment methods, the connection performance, corrosion resistance, and service life of threaded pup joints can be ensured. In practical applications, suitable thread forms and specifications should be selected according to specific needs to achieve the best usage effect. Through rigorous testing and quality control, the reliability and safety of threaded pup joints in various complex environments can be guaranteed.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :