What is ASTM A252?

ASTM A252 is the standard specification for welded and seamless steel pipe piles. It covers the nominal wall thickness of cylinder shape steel pipe, rectangular pipe is not included. These round pipes are used for piling purposes, playing as a permanent role of load carrying and bearing the pressure. Further more, to act as a tank shell to fill with the concrete piles at sight of the project.This standard stated the values units in inch-pound (also could be translated to SI units), which provides the reference A252 pipe data to engineer or designer, for a strength base of the constructions.The ASTM A252 standard covers steel piling pipe that is used in the construction industry for foundation applications. The ASTM A252 steel piling pipe is available in three grades based on strength levels: Gr.1, Gr.2, and Gr.3.

The A252 steel piling pipe is made to requirements that include chemical composition, mechanical properties, and dimensions. The A252 steel piling pipe can be ordered in both welded and seamless steel construction, and each type has its own advantages. Welded steel pipe offers a lower cost option for foundations, while seamless steel pipe provides a higher degree of strength and durability. ASTM A252 Grade 1 and Grade 2 steel piling pipe are suitable for most foundation applications, while Grade 3 steel pipe can be used for high-strength applications.

Chemical composition and mechanical properties of ASTM A252 pipe

The standard has a limit for element P (phosphorous) maximum 0.050%, since P will make steel fragile, and most important is not good for welding performances. ASTM A252 standard specifications only defines the conten of phosphorous, other elements accord with general carbon steel material.

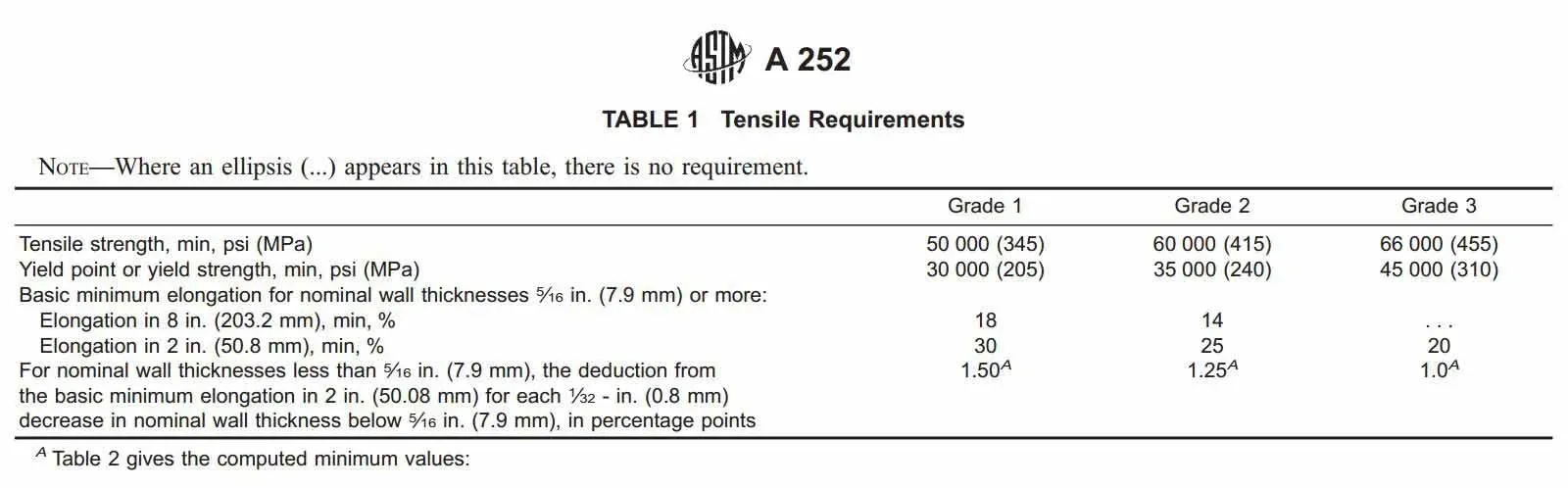

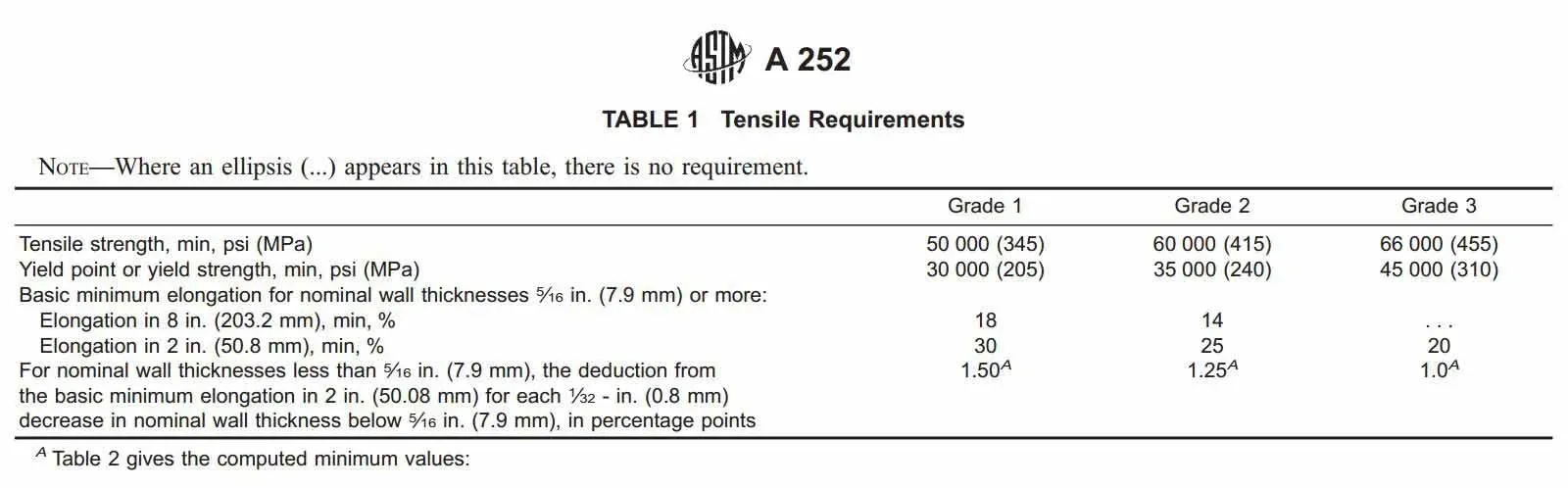

Mechanical Properties of A252 pipe

Reference standards for making ASTM A252 pipe

• ASTM A370 inspection methods and definitions for mechanical test of steel products.

• ASTM A751: Chemical analyze test methods.

• ASTM A941: Terminology for carbon, alloy and stainless steel.

• E29 practice for to use significant digits in test result to decide the conformance with specification.

ASTM A252 pile pipe material and manufacturing types

Considering on the manufacturing types, ASTM A252 pipe piles could be made by seamless or welded processes.

Seamless pipe pile

Seamless pipe pile referred as hot rolled or cold drawn and thermal expanded seamless pipe.

Welded pipe pile

Welded pipe pile including ERW (electric resistance welded), flash welded, fusion welded or sub-merged welded SSAW or LSAW. Longitudinal or helical spiral welded.

Raw material making process

Raw material iron and steel could be made through the process of Open-hearth, Basic-oxygen, Electric-furnace.

-Testing Requirements for seamless and welded A252 steel piling pipe

Hydrostatic Testing: Not specified.

Mechanical Tests:

Tensile Test: Either longitudinal or transverse at option of manufacturer.

Number of Tests: One tensile test per 200 lengths.

-Permissible Variations for A252 steel piling pipe

Wall thickness: Not more than 12.5% under the nominal wall thickness specified.

Weights per foot: The weight of any individuaL length of pipe shall not vary more than 15% over or 5% under the weight specified. Each individual length shall be weighed separately.

Outside diameter: Shall not vary more than plus or minus 1% from the diameter specified.

-Lengths of A252 steel piling pipe

baowi steel Tubular Products A252 steel piling pipe may be ordered in single or double random lengths or in uniform lengths.

Single random–16’– 2inclusive

Double random–Over 25’with a minimum average of 35’

Uniform – Plus or minus 1" on length specified

A252 steel pipe pile has three grades

Based on the tensile strength and the yield strength the ASTM A252 is classified into three categories/grades:

ASTM A252 Grade 1

ASTM A252 Grade 1 steel pipe pertains to pipe piles with a nominal (average) wall steel cylinder serving as a permanent load-carrying element or as a shell to build case-in-place concrete piles

ASTM A252 Grade 2

ASTM A252 Grade 2 steel pipe is one of the most commonly used pile pipes. Because of their tremendous strength, they are thought to be employed in applications that need strong structural qualities.

ASTM A252 Grade 3

ASTM A 252 Grade 3 has the highest mechanical properties, with better strength and corrosion resistance. Usually used for higher pressure and more important projects, such as large bridges, docks, harbors, etc.

ASTM A252 Grade 3: Most used piling pipe materials

In three grades of this standard, ASTM A252 Grade 3 pipe piling is the most common and used in piling activities. Because it has a higher tensile strength (455 Mpa or 66,000 psi) and yield strength (310 Mpa or 45,000 psi).

Testing Requirements for A252 steel pipe piling in seamless and welded

It includes:

Material analysis

Heat Analysis: Limits to elements P, and heat result shall be reported in MTC to customer.

Product Analysis: Test frequency shall be determined by the pipe diameter, where, under 14 inch 2 samples per 200 pieces, 14 to 36 inch 2 samples per 100 pieces, above 36 inch is 2 per 3000 ft.

Tensile requirements: Values shall be complied to the above tensile strength and yield strength. It shall be noted that if got a vague yield point, then to test yield strength corresponding to a permanent offset of 0.2% of the gage length of the sample specimen, or to test a total extension of 0.5% of the gage length under load.

Weight and dimension tolerances

Pipe pile weights per units (Feet, meter or lengths)

Tolerance allowed: A252 pipe pile weight shall be in +15% or -5% of theoretic weight. OD tolerances at +/-1%, wall thickness +/- 12%.

Lengths: As specified SRL, DRL, or fixed length 20 ft or 40 ft and customized.

Different than other pipelines

Hydrostatic test is not specified in ASTM A252 pipe specification, as normally piling pipe is filling with cement and concrete and forming, not for liquid transmission, so hydrotest is not required.

Different test methods for seamless and welded pipe piles

Seamless pipe , welded pipe, (Longitudinal or helical welded) test methods are different. Check ASTM A252 pipe standard specification for more details. But all of these types are tested in a room temperature.

Piling Pipe Prospective and Applications

Nowadays

piling pipe is developed to a direction with deep distance and big diameters usage, because the constructions, buildings, bridges now is getting higher even super higher. In United States or Japan steel pipe pile length has reached to 100 meter, diameters reach to 2500 mm. And in China even more.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :