ASTM A53 is a carbon steel alloy, used as structural steel or for low-pressure plumbing. The alloy specifications are set by ASTM International, in specification ASTM A53/A53M.

This specification covers seamless steel pipe and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26. The steel categorized in this standard must be open-hearth, basic-oxygen or electric-furnace processed and must have the following chemical requirements: carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium. The tubing shall undergo a seamless or welding process. Tension, bend, and flattening tests shall be performed to make sure that it must adhere to the mechanical properties of the standard. The hydrostatic test shall be applied, without leakage through the weld seam or the pipe body. Nondestructive electric test shall be made to make sure that the full volume of the pipe must be in accordance with the standard. The purchaser shall have the right to perform any of the inspections and tests set forth in this specification where deemed necessary to ensure that the pipe conforms to the specified requirements.

1. Scope of ASTM A53

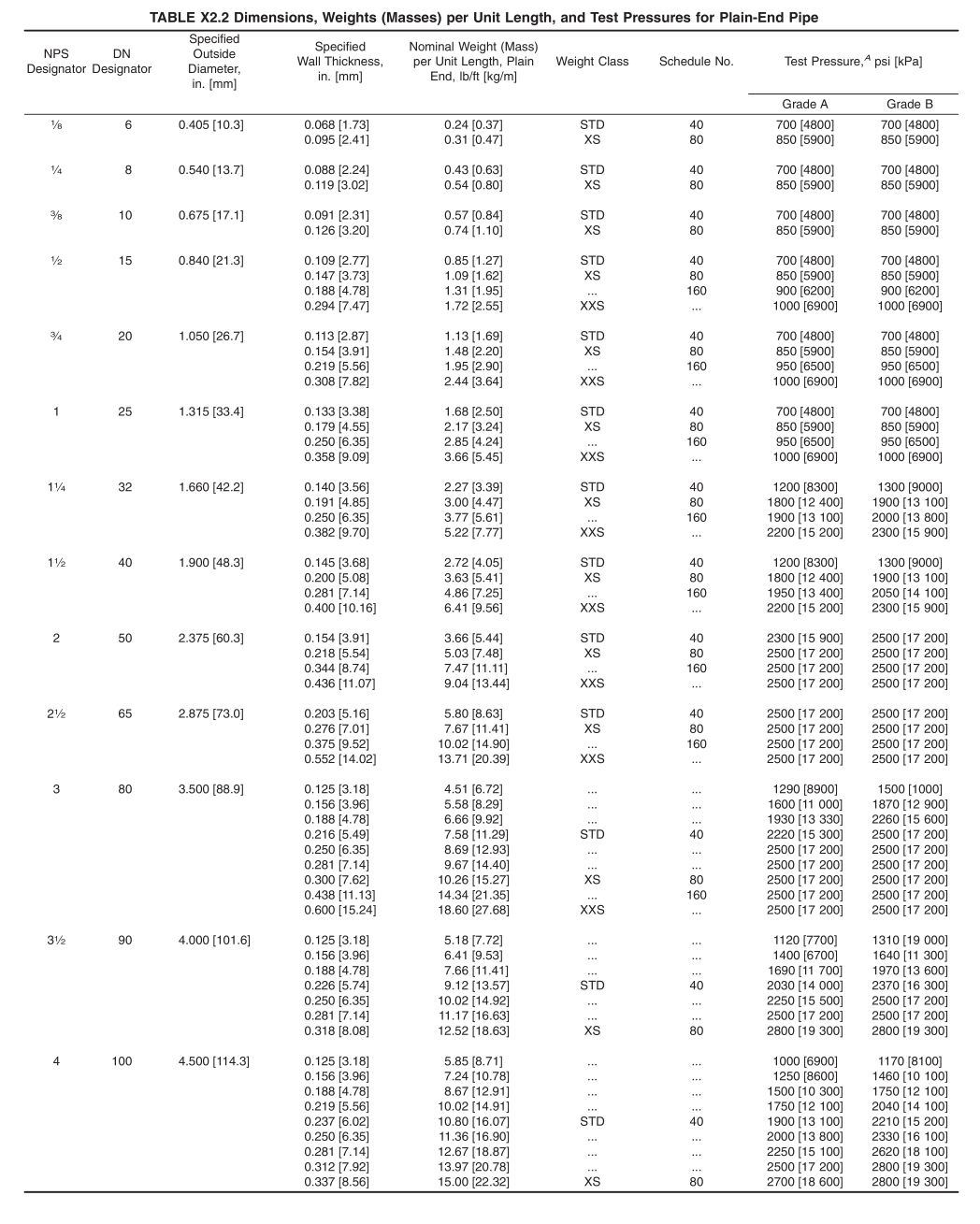

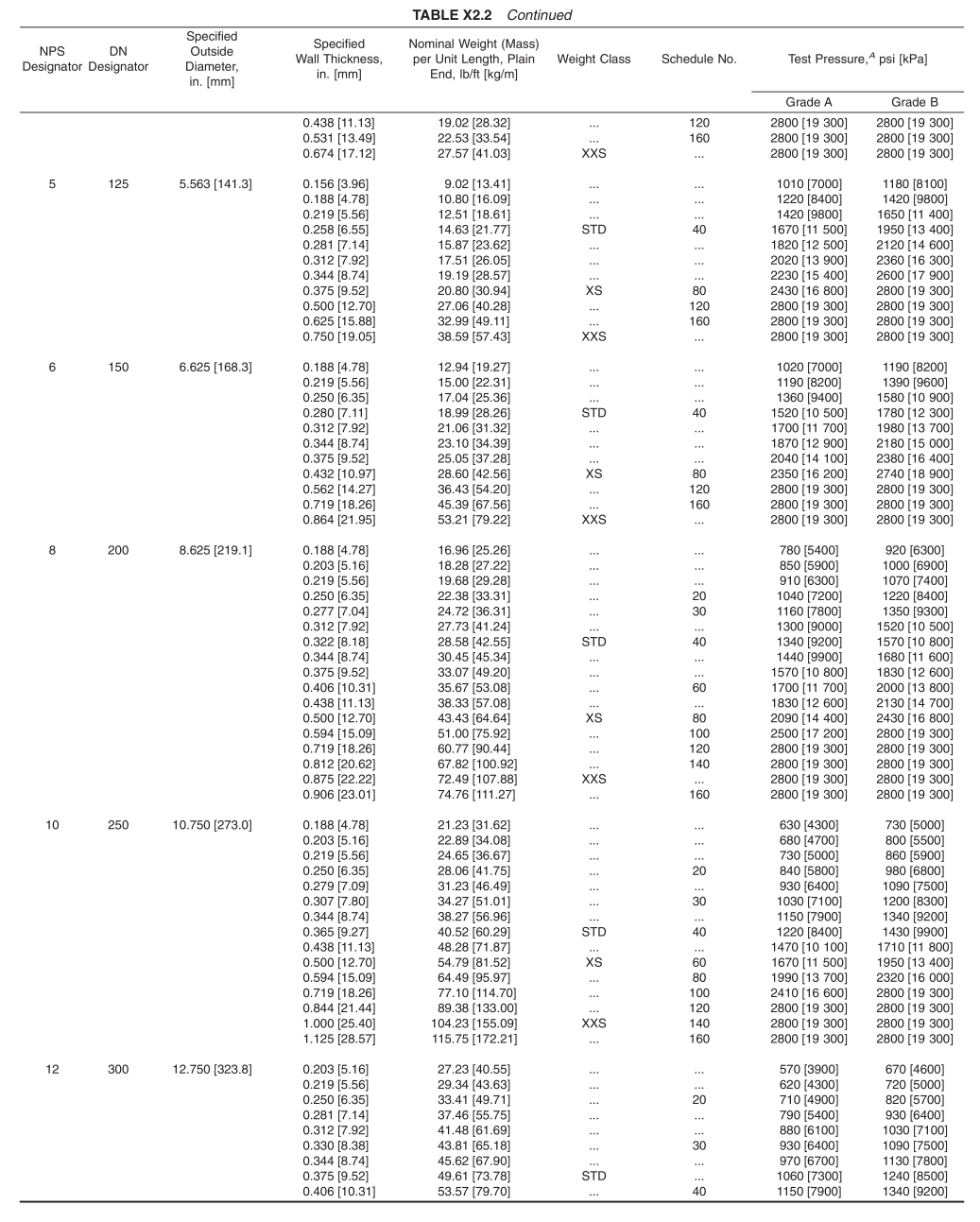

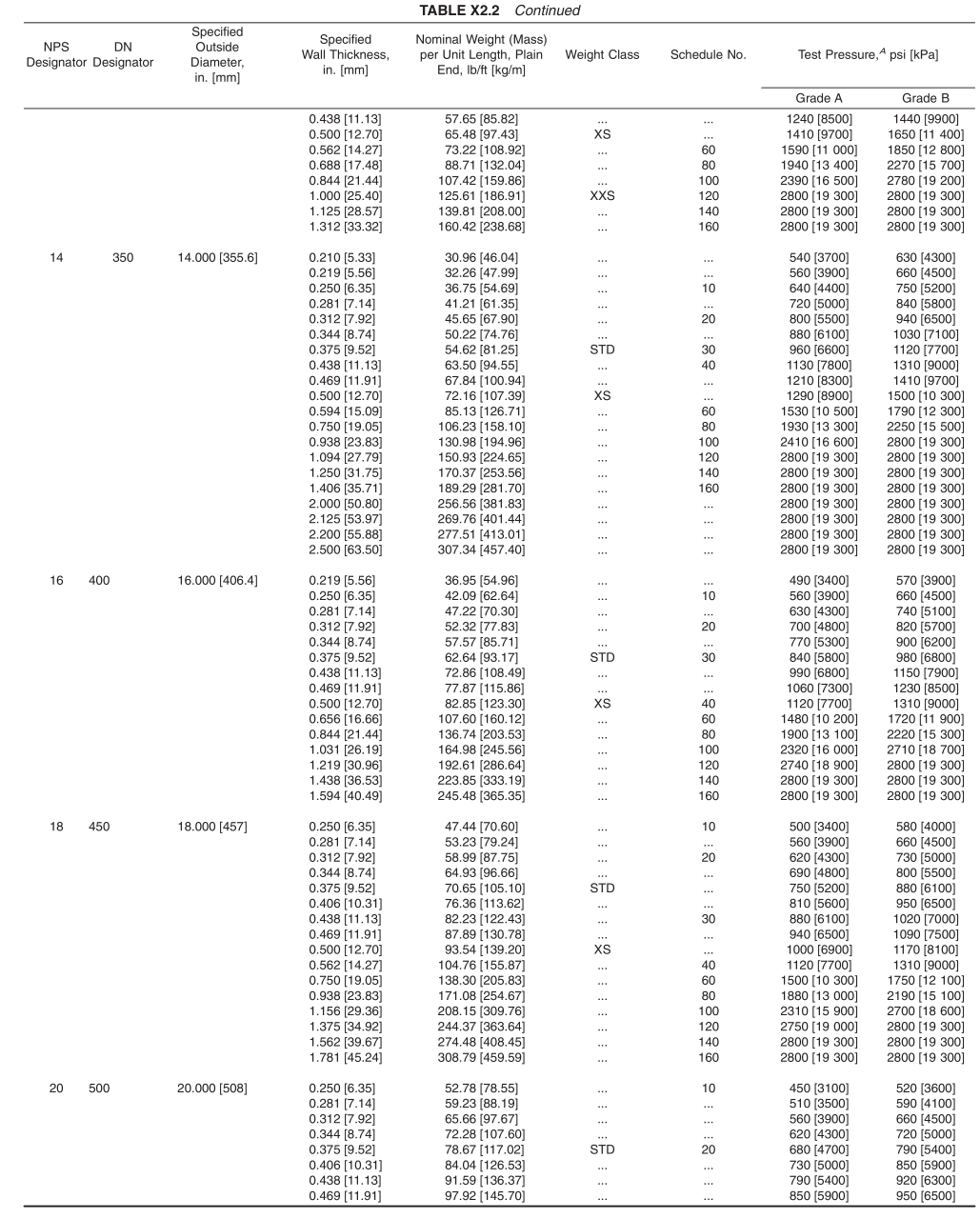

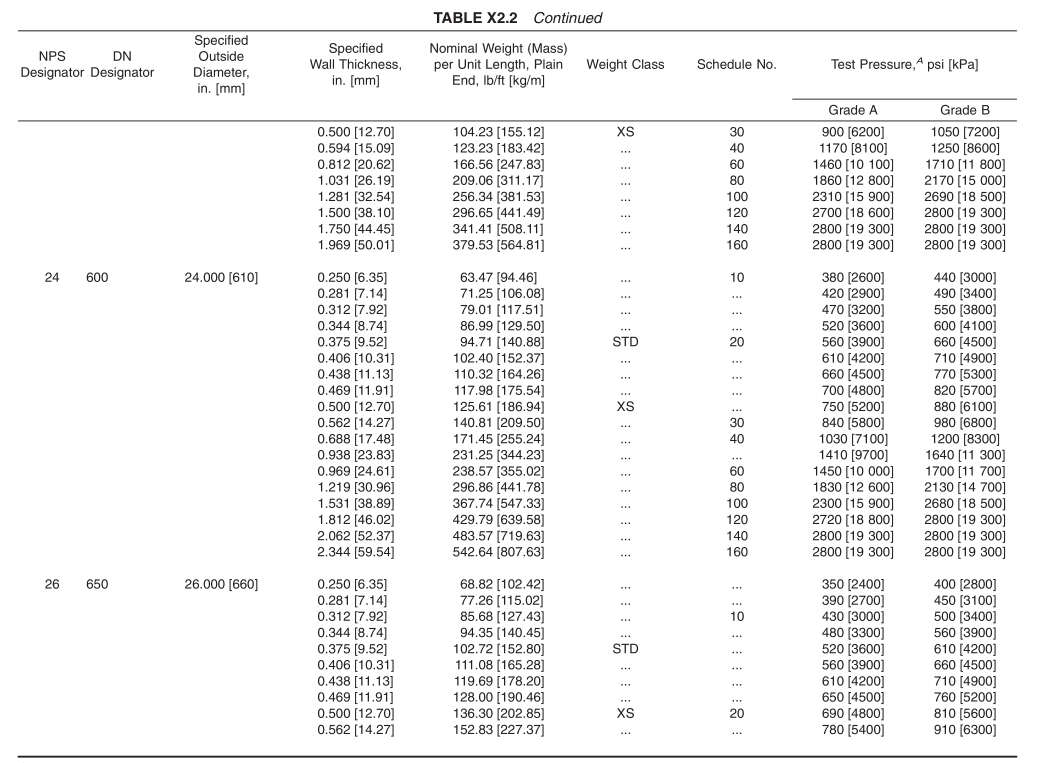

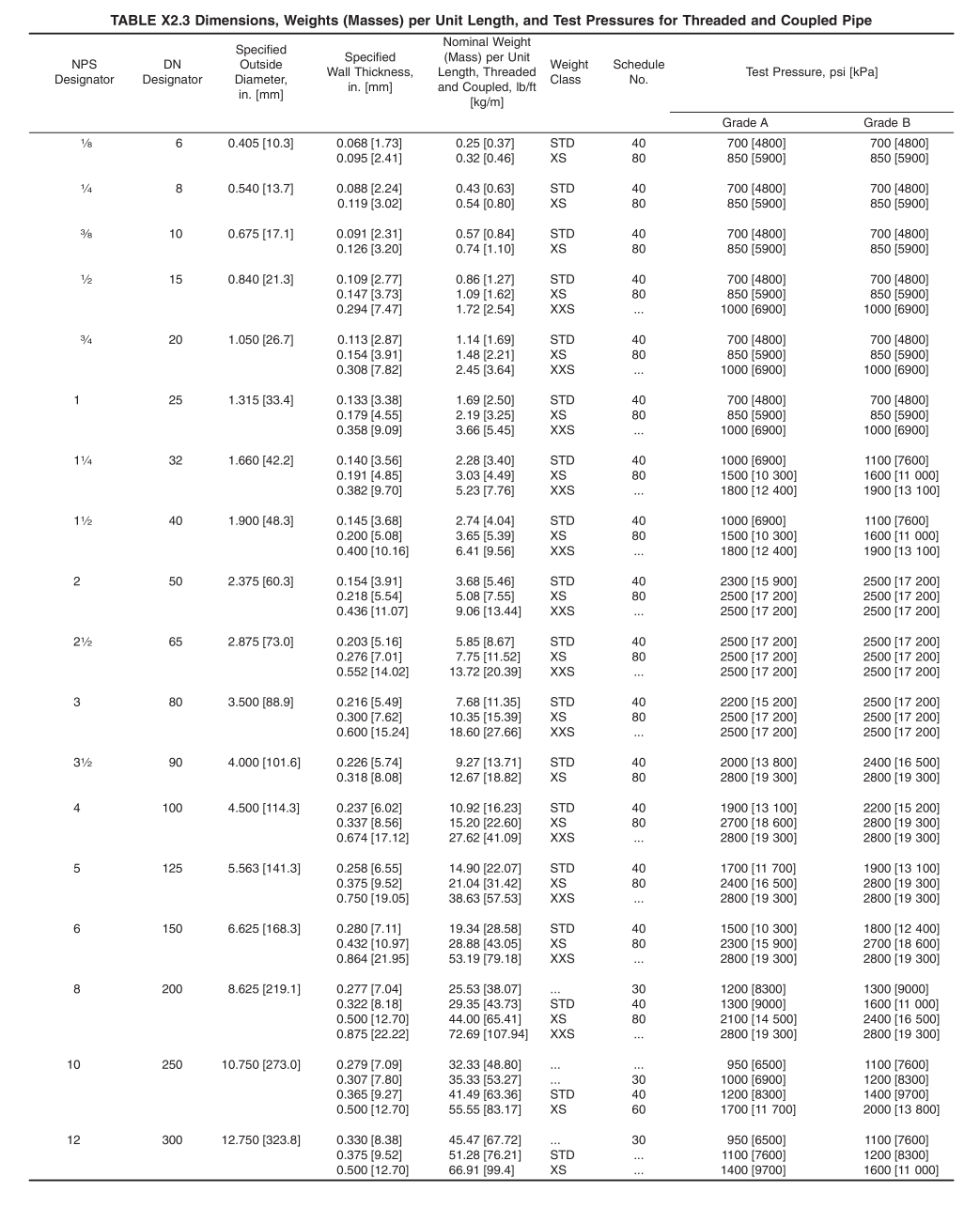

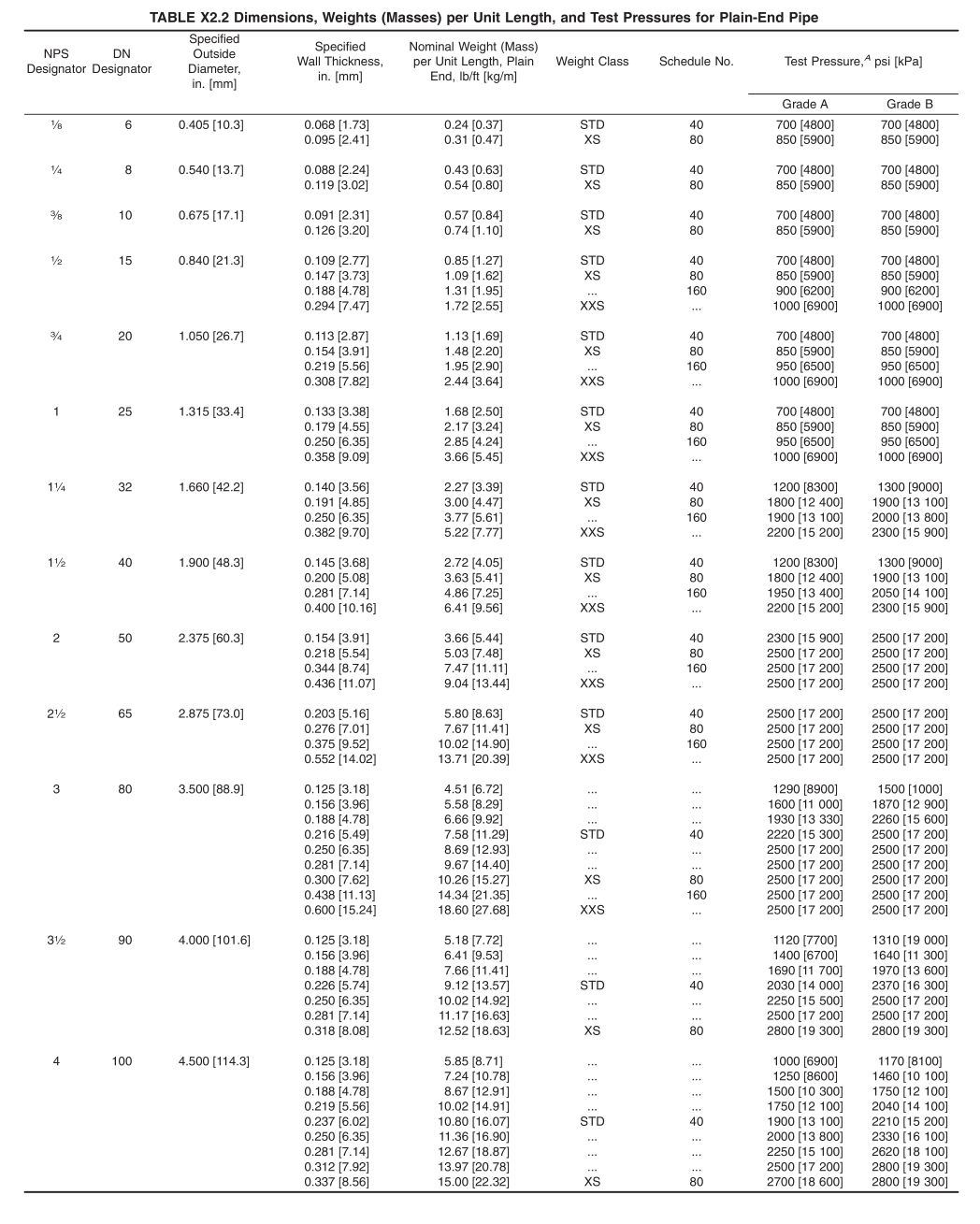

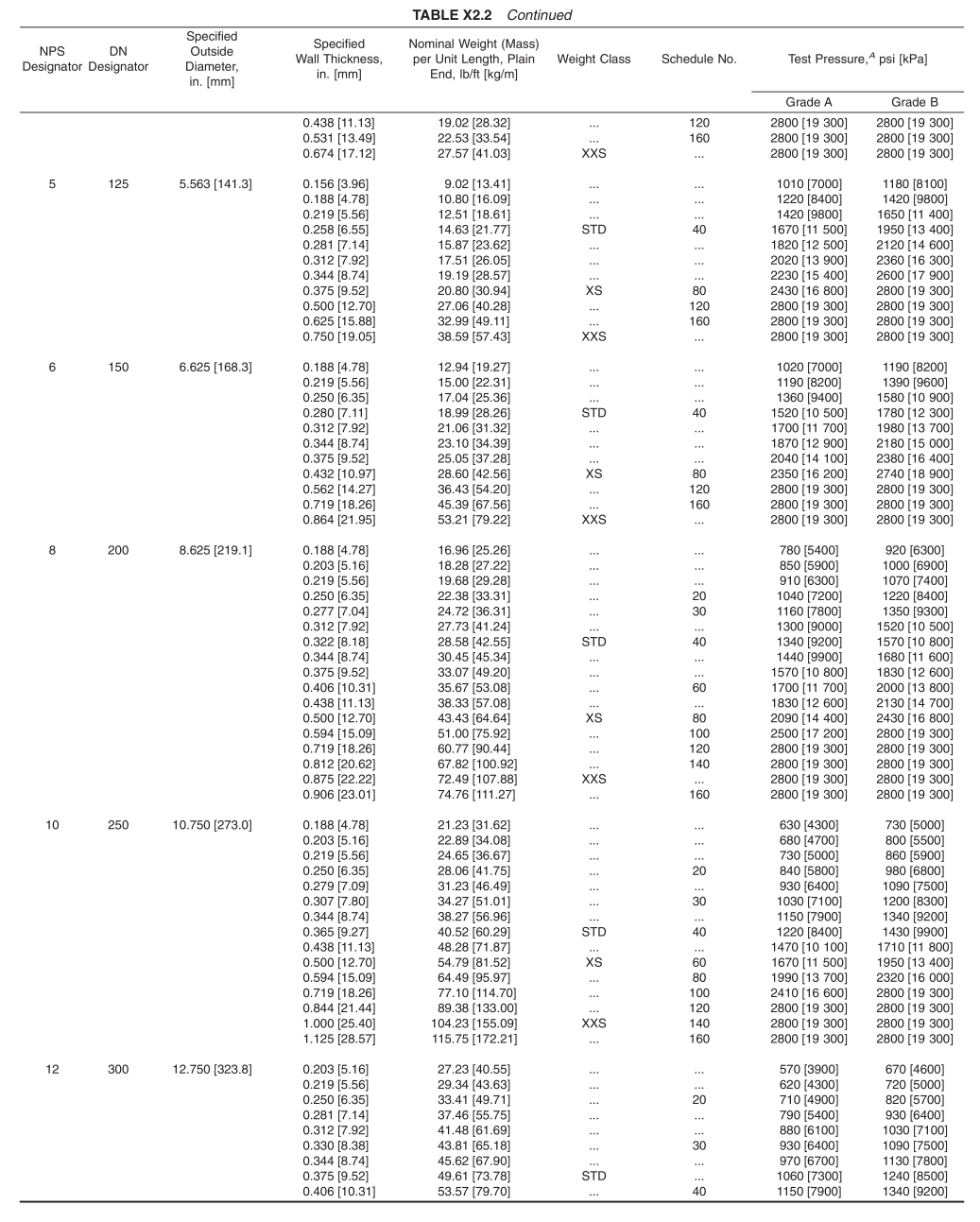

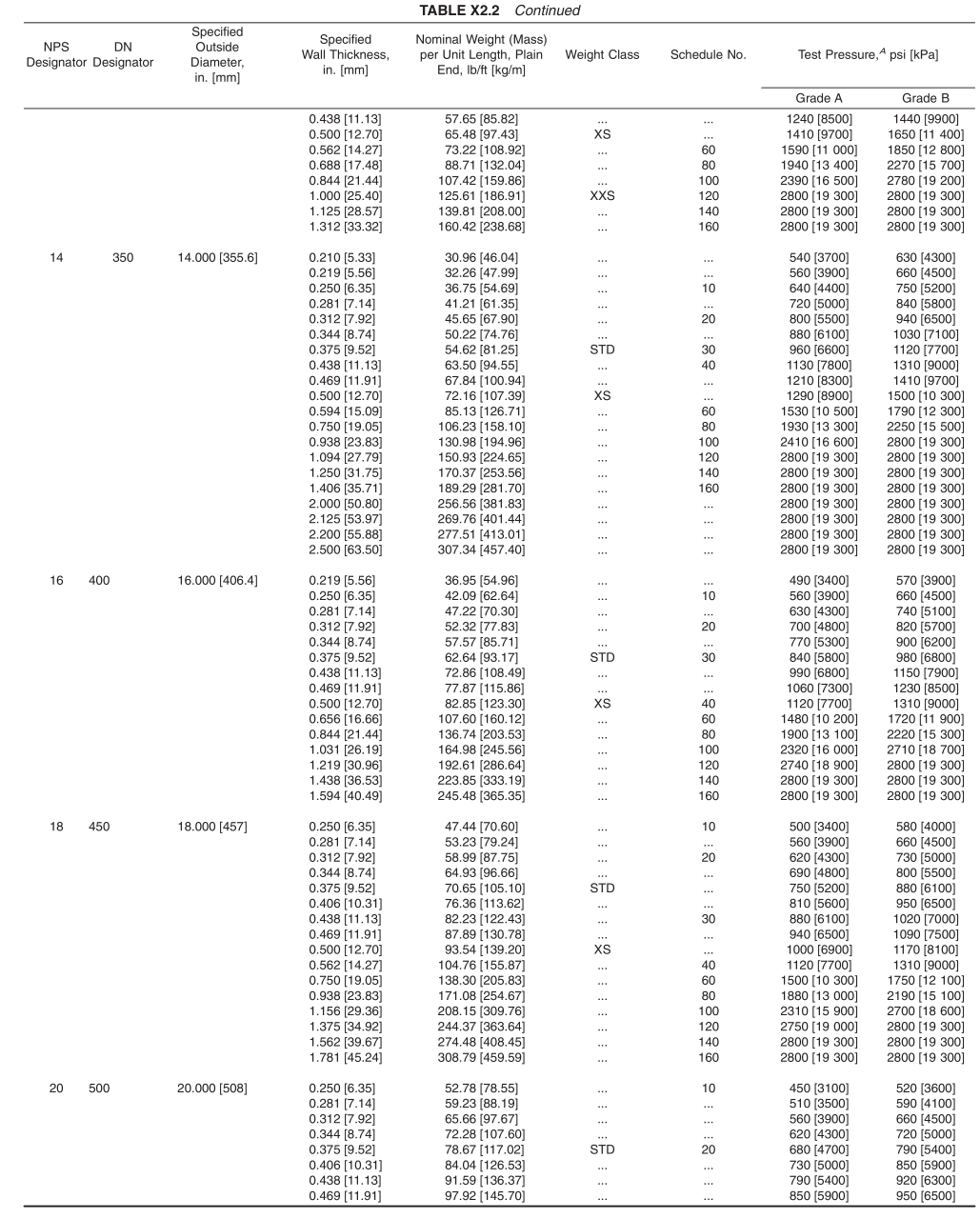

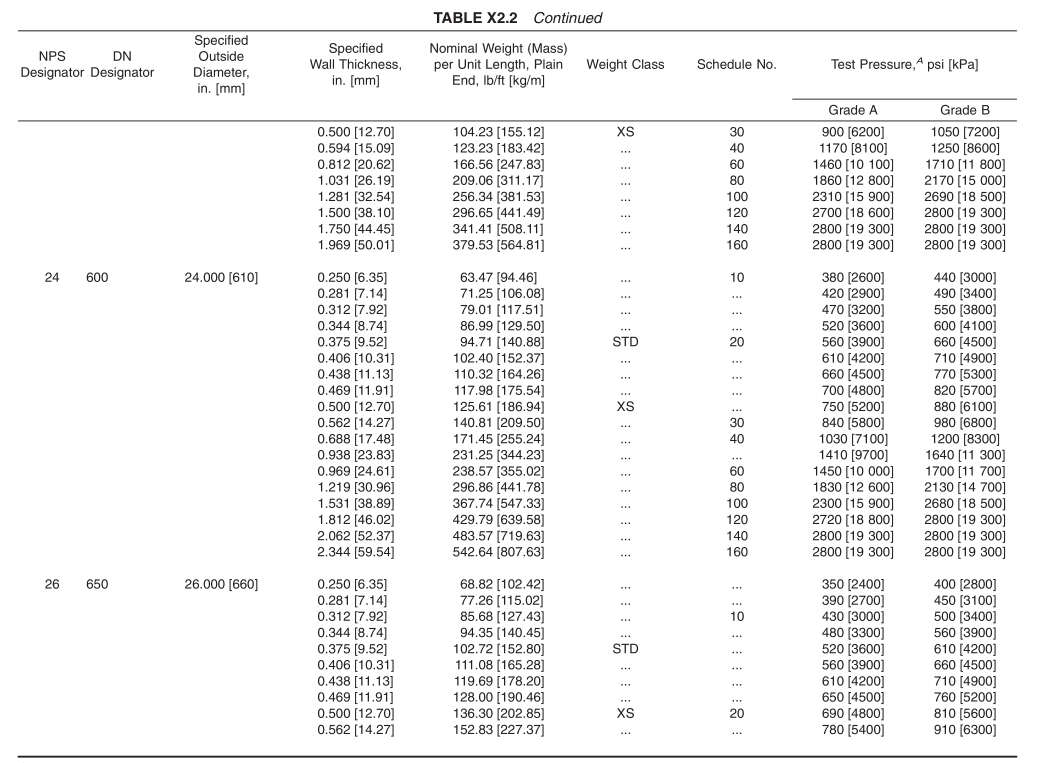

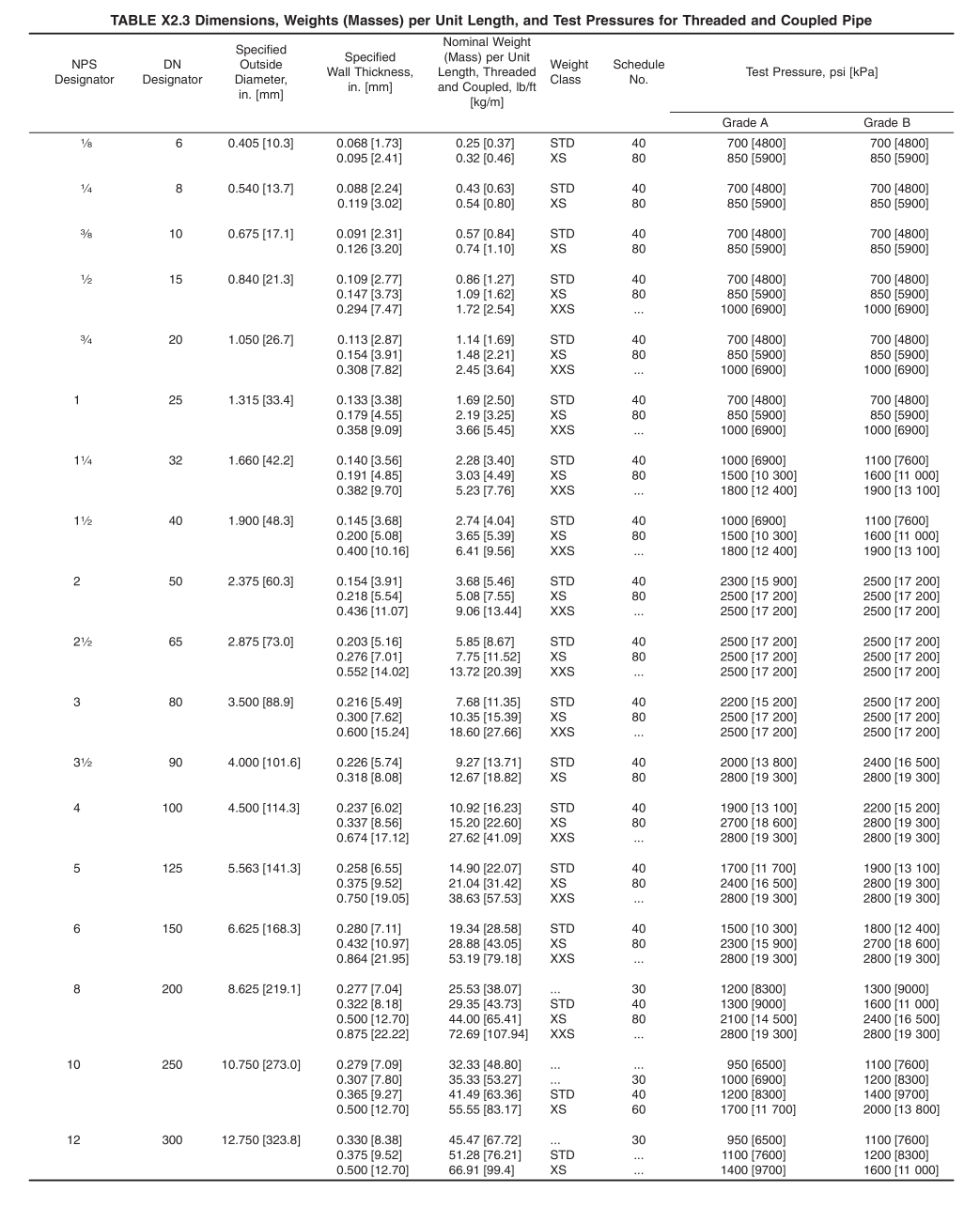

1.1 This specification 2 covers seamless and welded black and hot-dipped galvanized steel pipe in NPS1 ⁄ 8 to NPS 26 [DN6 to DN 650] , with nominal wall thickness as given in Table X2.2 and Table X2.3. It shall be permissible to furnish pipe having other dimensions provided that such pipe complies with all other requirements of this specification. Supplementary requirements of an optional nature are provided and shall apply only when specified by the purchaser.

NOTE 1—The dimensionless designators NPS (nominal pipe size) [DN(diameter nominal)] have been substituted in this specification for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

NOTE 2—The term nominal wall thickness has been assigned for the purpose of convenient designation, existing in name only, and is used to distinguish it from the actual wall thickness, which may vary over or under the nominal wall thickness.

A The minimum test pressure for outside diameters and wall thicknesses not listed shall be computed by the formula given below. The computed test pressure shall be used in all cases, except as follows:

(1) For specified wall thicknesses greater than the heaviest specified wall thickness listed in this table for the applicable specified outside diameter, the test pressure shall be the highest value listed for the applicable specified outside diameter and grade.

(2) For pipe smaller than NPS 2 [DN 50] with a specified wall thickness less than the lightest specified wall thickness listed in this table for the applicable specified outside diameter and grade.

(3) For all sizes of Grade A and B pipe smaller than NPS 2 [DN 50], the test pressures were assigned arbitrarily. Test pressures for intermediate specified outside diameters need not exceed those given in this table for the next larger listed size.

P52St/D

where:

P = minimum hydrostatic test pressure, psi [kPa],

S = 0.60 times the specified minimum yield strength, psi [kPa],

t = specified wall thickness, in. [mm],

D = specified outside diameter, in. [mm].

1.2 This specification covers the following types and grades:

(1)Type F—Furnace-butt-welded, continuous welded Grade A,

(2)Type E—Electric-resistance-welded, Grades A and B,

(3)Type S—Seamless, Grades A and B.

1.3 Pipe ordered under this specification is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas, and air lines. It is suitable for welding, and suitable for forming operations involving coiling, bending, and flanging, subject to the following qualifications:

(1)Type F is not intended for flanging.

(2) If Type S or Type E is required for close coiling or cold bending, Grade A is the preferred grade; however, this is not intended to prohibit the cold bending of Grade B pipe.

(3) Type E is furnished either nonexpanded or cold expanded at the option of the manufacturer.

(4)The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

(5) This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2.Materials and Manufacture of ASTM A53

(1) The steel for both seamless and welded pipe shall be made by one or more of the following processes: open-hearth,electric-furnace, or basic-oxygen.

(2) If steels of different grades are sequentially strand cast,identification of the resultant transition material is required.The steel producer shall remove the transition material by any established procedure that positively separates the grades.

(3)The weld seam of electric-resistance welded pipe in Grade B shall be heat treated after welding to a minimum of 1000 °F [540 °C] so that no untempered martensite remains, or otherwise processed in such a manner that no untempered martensite remains.

(4) When pipe is cold expanded, the amount of expansion shall not exceed1½% of the specified outside diameter of the pipe.

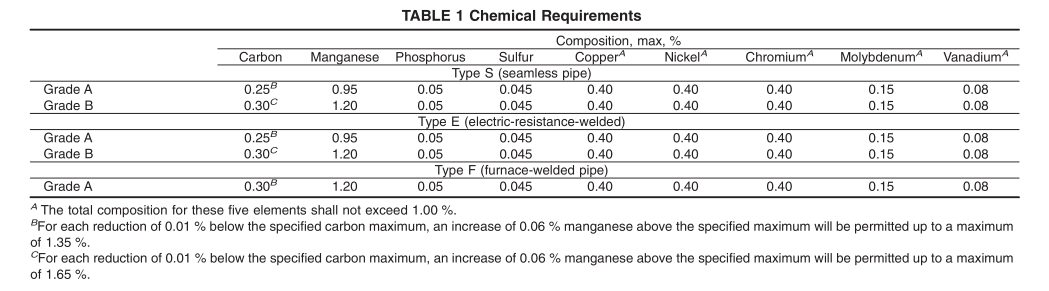

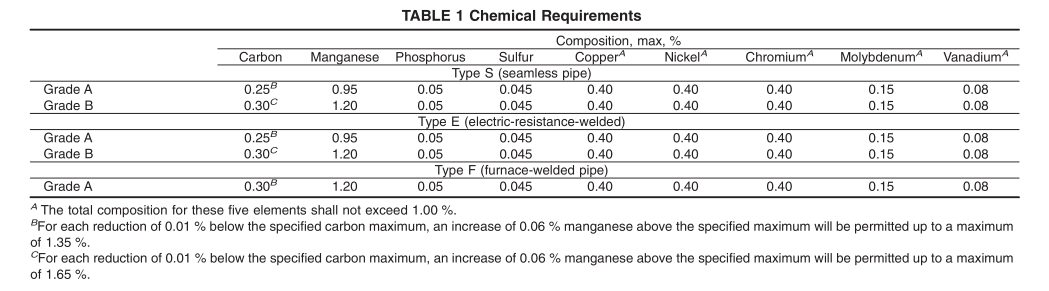

3.Chemical Composition of ASTM A53

(1) The steel shall conform to the requirements as to chemical composition given in Table 1 and the chemical analysis shall be in accordance with Test Methods, Practices,and Terminology A751.

4.Product Analysis of ASTM A53

(1)The purchaser is permitted to perform an analysis of two pipes from each lot of500 lengths, or fraction thereof. Samples for chemical analysis, except for spectrographic analysis, shall be taken in accordance with Practice E1806. The chemical composition thus determined shall conform to the requirements given in Table 1.

(2) If the analysis of either pipe does not conform to the requirements given in Table 1, analyses shall be made on additional pipes of double the original number from the same lot, each of which shall conform to the specified requirements.

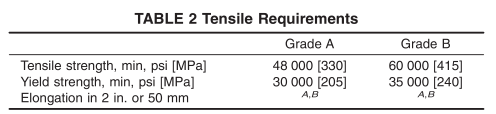

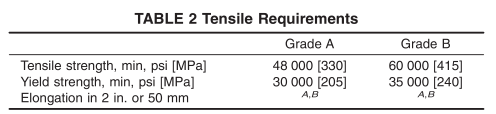

5. Mechanical Properties: Tensile strength and Yield strength

5. Mechanical Properties: Tensile strength and Yield strength

For ASTM A53 standard tensile tests other than transverse weld tension tests, the yield strength corresponding to a permanent offset of 0.2 % of the gage length or to an extension of 0.5 % of the gage length under load, the tensile strength, and the elongation in 2 in. or 50 mm shall be determined, and the tension test results shall conform to the applicable tensile property requirements given in the following chart:

6.Hydrostatic Checking

6.Hydrostatic Checking

Hydrostatic assessment examination stress for ordinary end as well as threaded and also coupled pipe are specified. Hydrostatic stress shall be maintained for not less than 5 seconds for all sizes of smooth as well as electric-resistance-weld pipe.

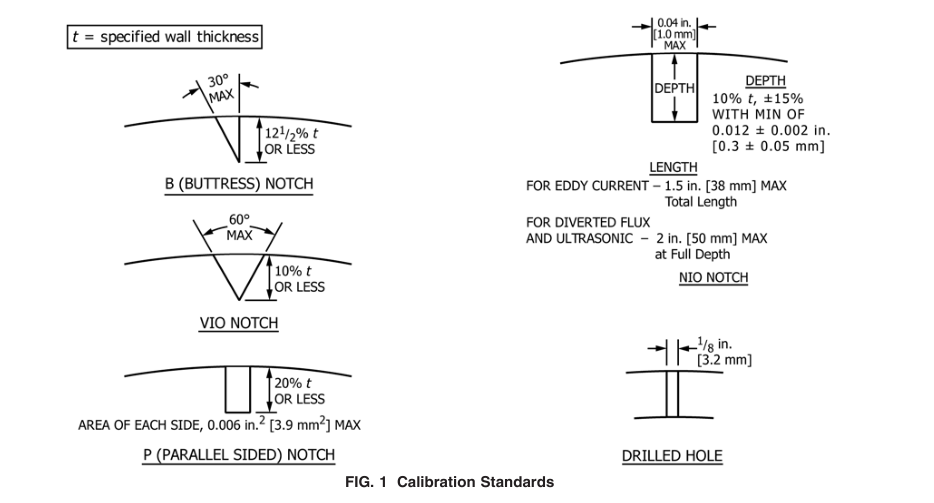

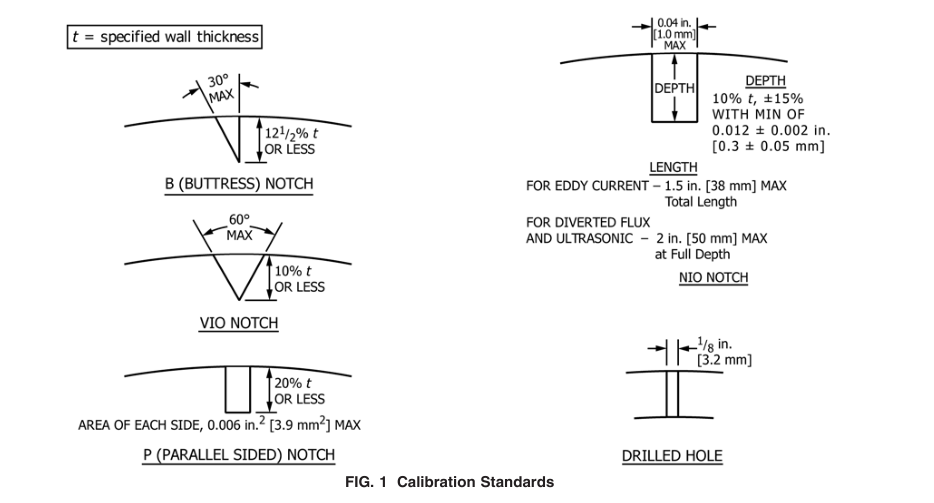

7.Calibration Standards:

8.Permissible Variations in Weight (Mass) and Dimensions

8.Permissible Variations in Weight (Mass) and Dimensions

(1)Weight (Mass)—The weight (mass) of the pipe shall not vary more than 6 10 % from its specified weight (mass), as derived by multiplying its measured length by its specified weight (mass) per unit length.

NOTE 6—For pipe NPS 4 [DN 100] or smaller, the weight (mass) tolerance is applicable to the weights (masses) of the customary lifts of pipe as produced for shipment by the mill. For pipe larger than NPS 4 [DN100], where individual lengths are weighed, the weight (mass) tolerance is applicable to the individual lengths.

(2)Diameter—For pipe NPS 1 1 ⁄ 2 [DN 40] or smaller, the outside diameter at any point shall not vary more than 61 ⁄ 64 in.[0.4 mm] from the specified outside diameter. For pipe NPS 2[DN 50] or larger, the outside diameter shall not vary more than 6 1 % from the specified outside diameter.10.3 Thickness—The minimum wall thickness at any point shall be not more than 12.5 % under the specified wall thickness.

9.Test Methods of ASTM A53

(1)The test specimens and the tests required by this specification shall conform to those described in the latest issue of Test Methods and Definitions A370.

(2)Each longitudinal tension test specimen shall be taken from a pipe end and shall not be flattened between the gage marks.

(3)Test specimens for bend tests and flattening tests shall be taken from pipe. Test specimens for flattening tests shall be smooth on the ends and free from burrs.

(4)Tests shall be conducted at room temperature.

10.Inspection of ASTM A53

The inspector representing the purchaser shall have entry, at all times while work on the contract of the purchaser is being performed, to all parts of the manufacturer’s works that concern the manufacture of the pipe ordered. The manufacturer shall afford the inspector all reasonable facilities to be satisfied that the pipe is being furnished in accordance with this specification. All tests (except product analysis) and inspection shall be made at the place of manufacture prior to shipment,unless otherwise specified, and shall be so conducted as not to interfere unnecessarily with the operation of the works.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :