Seamless (SMLS) steel pipe, with its seamless welds, smooth interior, and uniform wall thickness, is widely used in fluid transportation systems, mechanical structures, and energy engineering applications under high pressure, high temperature, and harsh operating conditions. The safety and reliability of seamless pipes are particularly crucial to the stable operation of the entire system in fields such as petrochemicals, power generation, boilers, and pressure vessels. The pressure-bearing capacity of seamless pipes directly determines their application range, making the calculation of pressure on seamless pipes extremely important.

What is seamless pipe?

Seamless pipe is a metal pipe made from a single round steel billet through a series of processes, including heating, piercing, rolling, sizing, and cooling. Compared to welded pipe, seamless pipe has no weld weaknesses and a more uniform and dense overall structure, allowing it to withstand higher pressures and temperatures. Its manufacturing process ensures high strength and reliability, making it a preferred material for high-pressure fluid transportation, power equipment, and structural applications.

Key features include:

High pressure bearing capacity: The pipe wall is uniform and has good structural continuity, making it suitable for high-pressure transmission.

Excellent high-temperature resistance: It maintains strength and stability even in high-temperature environments.

Long service life: It has excellent corrosion resistance and a high safety factor.

Basic Calculation Formula for Seamless Pipe Pressure

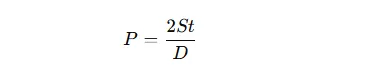

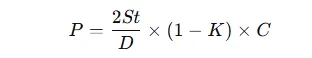

In engineering practice, the following basic formula is commonly used to calculate seamless pipe pressure:

Where:

P — Pressure bearing capacity of seamless pipe (unit: MPa)

S — Tensile strength of seamless pipe material (unit: MPa)

t — Pipe wall thickness (unit: mm)

D — Outer diameter of steel pipe (unit: mm)

This formula is the fundamental theoretical basis for calculating pressure for seamless pipes. It can be seen that the pressure bearing capacity of seamless pipes is directly proportional to the wall thickness and inversely proportional to the pipe diameter. Furthermore, the tensile strength of the material is also an important factor in determining the upper limit of pressure bearing capacity.

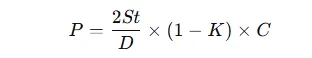

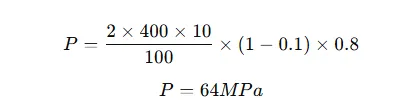

Corrected Formulas for High Temperature and High Pressure

In practical applications, many seamless pipes operate under high temperature and high pressure. The effects of temperature and pressure on material properties must be considered. Material strength decreases at high temperatures, and stress concentrations occur under pressure. Therefore, the basic formulas require corrections:

Where:

K is the temperature coefficient, used to correct for the effects of high temperatures on material strength.

C is the pressure coefficient, corrected for different pressure levels.

This correction method is more consistent with engineering practice and effectively reflects the material's pressure-bearing capacity under harsh operating conditions.

Method for Expressing the Pressure Coefficient of Seamless Pipes

In high-pressure pipeline design, engineers typically use different coefficients to adjust for different pressure levels. Common pressure coefficient values are as follows:

When P < 7 MPa, coefficient S = 8

When 7 < P < 17.5 MPa, coefficient S = 6

When P > 17.5 MPa, coefficient S = 4

This correction method can effectively increase the safety factor in the design, ensuring the stability and reliability of seamless pipes in long-term operation.

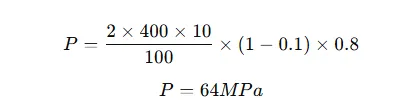

Seamless Pipe Pressure Calculation Example

Assume the following parameters for a steel pipe:

Outer diameter D = 100 mm

Wall thickness t = 10 mm

Material tensile strength S = 400 MPa

Temperature coefficient K = 0.1 for operating environment

Pressure coefficient C = 0.8

Then the pressure capacity is:

Factors Affecting the Pressure-Bearing Capacity of Seamless Pipes

1. Material Strength

The tensile strength of different steel grades varies. For example, commonly used materials such as

sch 20, Q345B, and 16Mn have varying tensile strength ranges. For high-pressure applications, higher-strength alloy steel or stainless steel is often selected.

2. Pipe Wall Thickness

The thicker the wall, the higher the pressure-bearing capacity. However, increased wall thickness also increases weight and cost, so a reasonable choice should be made based on the operating conditions.

3. Pipe Diameter

The larger the pipe diameter, the lower the pressure-bearing capacity. Therefore, large-diameter, high-pressure pipes often require thicker walls.

4. Operating Temperature

High temperatures can cause steel strength to decrease, which must be corrected using the temperature coefficient K.

5. Welding and Processing

Although seamless pipes do not have welds, weak links may exist during the joining and processing process, which can also affect the overall pressure-bearing capacity.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :