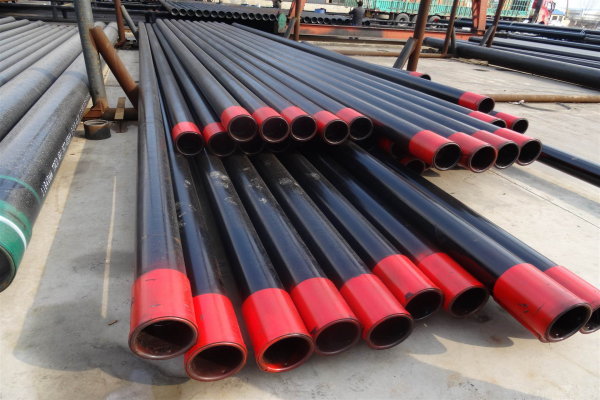

Oil casing pipe is the oil layer casing

pipe used when drilling to the target layer (oil, gas). It is mainly used to seal the oil, gas layer and the upper exposed strata. The inside of the casing is the oil layer.Casing is a series of steel pipes that are inserted into the drilled oil well to stabilize the oil well, prevent pollutants and water from entering the oil flow, and prevent oil from seeping into the groundwater. The casing is installed in layers, and the diameter of each part is gradually reduced, and then connected together to form a casing string. There are five types of casing strings: guide casing, surface casing, intermediate casing, casing liner and production casing.Casing

pipe is usually made of carbon steel, and it is usually made of

seamless steel pipe. But as the main structural component of the oil well, the steel grade used to make the casing

pipe and the specifications of the finished material are very important.

Oil casing

pipe standard: API SPEC 5CT,

API5CT is the oil casing

pipe standard formulated by the American Petroleum Institute, including different grades of casing, such as H40, J55, K55, N80, L80, C90, C95, P110 and Q125.

ISO 11960: Oil casing pipe standard formulated by the International Organization for Standardization, similar to API 5CT, including different grades of casing pipe.

GB/T 9711.1: Oil casing pipe standard formulated by the China National Organization for Standardization, including L175, L210, L245, L290, L320, L360, L390, L415, L450, etc.

SY/T6194: Oil casing pipe standard formulated by China's petrochemical industry standard, including casing and tubing types used in different depths and conditions of oil wells.

Length range: R1 (6.10m~7.32m), R2 (8.53~9.75m), R3 (11.58m-12.80m)

Oil casing steel grade: H40, J55, K55, N80, L80, C90, T95, P110, Q125, V150.

Thread type: LTC, STC, BTC, VAM, EUE, NUE

Calculation of casing pipe weight:

[(outer diameter-wall thickness)*wall thickness]*0.02466=kg/m (weight per meter)

Chemical composition of casing pipe:

(1) According to SY/T6194-96, the casing and its coupling are of the same steel grade, with sulfur content <0.045% and phosphorus content <0.045%;

(2) Take chemical analysis samples according to GB/T222-84 and conduct chemical analysis according to the relevant parts of GB223;

(3) Conduct according to the first edition of API SPEC 5CT 1988 of the American Petroleum Institute. Chemical analysis samples are prepared according to the latest version of ASTME59 and chemical analysis is conducted according to the latest version of ASTME350.

Physical properties of casing pipe:

(1) Conduct according to SY/T6194-96. Flattening test (GB246-97), tensile test (GB228-2010) and hydraulic test;

(2) Hydrostatic test, flattening test, sulfide stress corrosion cracking test, hardness test (performed in accordance with the latest version of ASTME18 or E10), tensile test, transverse impact test (performed in accordance with the latest version of ASTMA370, ASTME23 and related standards), grain size determination (performed in accordance with the latest version of ASTME112 or other methods).

Mechanical Properties:

(1) Domestic casing pipe shall be implemented in accordance with SY/T6194-96, and the casing length is variable, ranging from 8 to 13m. However, casing not shorter than 6m can be provided, and the number shall not exceed 20%.

(2) There shall be no defects such as folding, hairline, delamination, cracks, creases, scarring, etc. on the inner and outer surfaces of the casing pipe. These defects shall be completely removed, and the removal depth shall not exceed 12.5% of the nominal wall thickness. (3)

There shall be no defects such as folding, hairline, delamination, cracks, creases, scarring, etc. on the outer surface of the coupling.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :