When choosing a water pipe material, there are generally two options: ductile iron pipe (DIP) and PVC pipe. Both offer unique advantages, differing in material properties, application scenarios, and cost. Ductile iron pipe is primarily used for high-pressure, high-strength water supply and drainage piping, while PVC pipe is more commonly used for drainage and water supply in low-pressure, corrosive environments, as well as for internal building water supply and drainage.

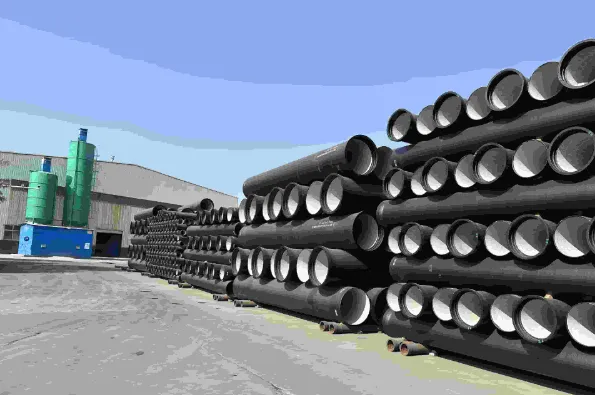

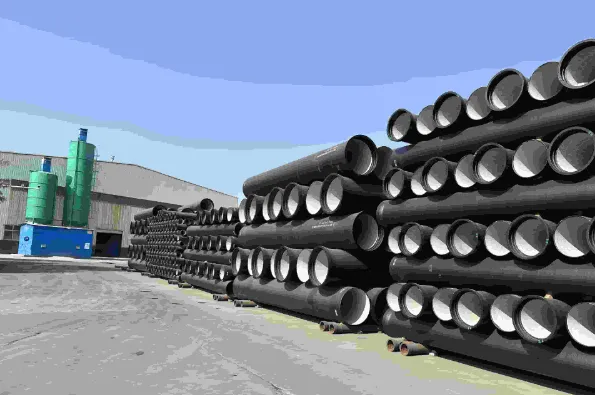

What does "ductile iron pipe" mean?

Cast iron steel pipe is essentially ductile iron pipe, so-called because it possesses the properties of steel with the essence of iron. The graphite in ductile iron pipe is spherical, typically with a size of 6-7. Quality requirements for cast iron pipes are controlled to a spheroidization level of 1-3, with a spheroidization rate of 80% or higher. This significantly improves the material's mechanical properties, allowing it to possess the essence of iron with the properties of steel. After annealing, the metallographic structure of ductile iron pipe is ferrite with a small amount of pearlite, resulting in excellent mechanical properties, hence its name, cast iron steel pipe

PVC Pipe

PVC (Polyvinyl Chloride) Pipe is a lightweight plastic pipe widely used in construction and plumbing. It is non-metallic, corrosion-resistant, and easy to install.

Weight: Very light, easy to transport.

Lifespan: 50–70 years depending on soil and exposure.

Best Use: Residential plumbing, irrigation, and low-pressure water systems.

What's the difference between ductile iron pipe and PVC pipe?

Ductile iron pipe and PVC pipe are two common pipe materials. The key differences are as follows:

1. Material and Performance

Ductile iron pipe: Made of iron with spherical graphite distribution, it offers high strength (tensile strength ≥420 MPa), high pressure resistance (1.0-2.5 MPa), impact resistance, and a wide temperature range (-30°C to 150°C). However, it is heavy and expensive.

PVC pipe: Made of PVC resin, it offers low strength (tensile strength 40-60 MPa), low pressure resistance (≤1.6 MPa), high brittleness (prone to cracking at low temperatures), and low temperature resistance (≤60°C). However, it is lightweight, corrosion-resistant (naturally resistant to acids and alkalis), and low cost.

2. Production and Connections

Ductile iron pipe: Made using a centrifugal casting process, its joints are either flexible rubber rings (to accommodate settling) or rigid connections, and require an anti-corrosion coating. PVC pipe: Made of extruded plastic, connections are made with solvent glue (for small pipes) or rubber rings (for large pipes). No corrosion protection is required.

3. Applications

Ductile iron pipe: Suitable for municipal water supply mains, gas transmission, high-pressure drainage, and industrial corrosive media (requires coating). Lifespan: 50+ years.

PVC pipe: Suitable for low-pressure water supply and drainage (such as household laterals), agricultural drip irrigation, short-term projects, and corrosive fluids (such as clean wastewater). Lifespan: 20-30 years.

4. Cost-Effectiveness

Ductile iron pipe has a higher initial cost but is durable and requires minimal maintenance. PVC pipe is cheaper but is more fragile and requires regular replacement.

Comparing cast iron drainage pipes vs. plastic pipes: Which is better? How do you choose?

Cast iron drainage pipes are excellent silent pipes, often using rubber-sealed joints. This flexible connection effectively blocks the transmission of sound from the water flowing through the pipe. The dense microstructure of gray cast iron and its flake graphite structure effectively absorb vibration energy, significantly reducing noise transmission.

Corrosion-resistant: Made from gray cast iron, which, unlike ordinary steel, generally contains 2.5-4% carbon, all or most of which is in the form of free graphite within the gray cast iron structure.

Aging-resistant: Unlike polymer-based pipes, cast iron drainage pipes do not age with extended use, temperature fluctuations, or sunlight. They offer a long service life.

Excellent strength and wear resistance: The tensile strength of cast iron drainage pipes is generally greater than 150 MPa, three to four times the strength of chemical drainage pipes like PVC. Cast iron pipes offer excellent compressive strength when used in buried pipe construction, preventing tree root penetration and rodent gnawing damage.

Fire Resistance: Cast iron piping systems offer numerous advantages over alternative materials in terms of fire resistance. Cast iron pipes are non-combustible, meaning they will not burn in a building fire.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :