When choosing flanges for industrial piping systems, understanding the difference between gray cast iron and ductile iron is crucial. Both materials are iron-based alloys, but they have distinct chemical compositions, mechanical properties, and pressure ratings. These differences significantly influence performance, durability, and cost. In this article, we explore how gray iron and ductile iron flanges compare, including their structural characteristics, pressure tolerances, and suitability for various applications.

What is Gray Cast Iron?

Gray cast iron, often referred to simply as cast iron, has been used for centuries in construction and manufacturing. It typically consists of:

96%–98% iron

2%–4% carbon

Small amounts of silicon

When gray cast iron solidifies, graphite flakes form within the grain structure. These flakes are visible under magnification and appear as jagged lines. While these flakes provide compressive strength and excellent vibration damping, they also act as points of weakness, making gray iron brittle under tension or bending stress.

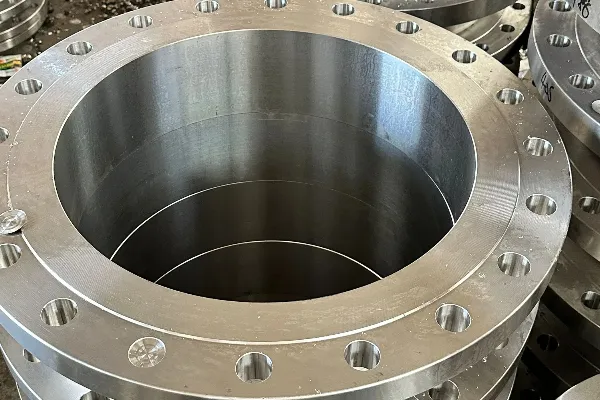

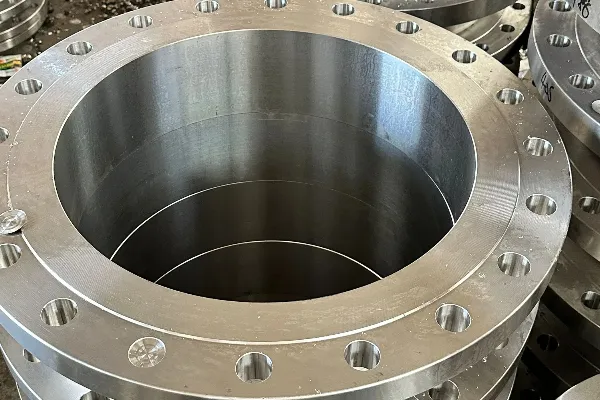

Definition of Ductile iron flange

Ductile iron flanges are components used to connect pipes, valves, and other equipment in piping systems, primarily in above-ground applications. They are made from ductile iron, a type of cast iron known for its strength and flexibility, making them suitable for high-pressure and high-temperature environments.

Pressure and Temperature Ratings of Flanges

Gray Cast Iron Flange Ratings

Pressure ratings for gray iron flanges are typically categorized into:

Class 125: Rated for 150–200 psi at moderate temperatures

Class 250: Rated for 300–500 psi

Gray cast iron can withstand temperatures up to 2100°F (1150°C), making it suitable for many high-heat applications. However, due to its brittleness, it is not ideal for systems experiencing dynamic or shock loads.

Ductile Iron Flange Ratings

Ductile iron flanges are generally rated under:

Class 150: Up to 250 psi

Class 300: Up to 640 psi

The temperature tolerance of ductile iron is slightly lower than that of gray iron, typically up to 1350°F (730°C). Still, the material’s superior mechanical properties enable it to handle higher working pressures and more aggressive service conditions.

When selecting flange materials for piping systems, it's important to understand the key differences between gray cast iron and ductile iron. Though both are cast iron alloys, their internal structures and mechanical properties result in different applications and performance levels.

Gray Cast Iron vs. Ductile Iron Flanges

When selecting flange materials for piping systems, it's important to understand the key differences between gray cast iron and ductile iron. Though both are cast iron alloys, their internal structures and mechanical properties result in different applications and performance levels.

1.Structure and Graphite Form

Gray cast iron contains graphite in flake form, which weakens the metal matrix and creates stress concentration points. This makes the material brittle with low ductility. In contrast, ductile iron has graphite in spherical (nodular) form, reducing internal stress and allowing the material to bend without cracking.

2.Mechanical Strength and Durability

Gray cast iron offers good compressive strength and excellent vibration damping, but it lacks toughness and cannot handle impact or bending. It typically cannot be heat treated to improve strength. Ductile iron, however, has higher tensile and yield strength and can be heat treated. It performs well under high pressure, impact, and dynamic loads.

3.Pressure and Temperature Ratings

Gray cast iron flanges are commonly rated as Class 125 (150–200 psi) or Class 250 (300–500 psi), and can withstand temperatures up to 2100°F (1150°C). Ductile iron flanges are rated at Class 150 (up to 250 psi) and Class 300 (up to 640 psi), with a temperature limit around 1350°F (730°C).

4.Typical Applications

Gray iron flanges are used in low-pressure, static environments such as water lines, HVAC systems, and fire protection piping. Ductile iron flanges are suited for demanding systems like municipal water, gas pipelines, and oil transport where high strength and reliability are required.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :