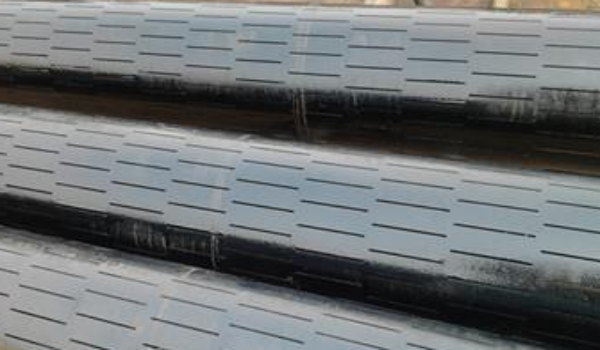

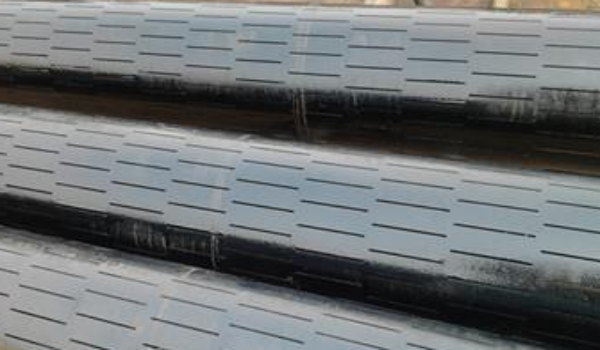

Slotted casings are essential tools in oil drilling, especially for mechanical sand control. With proper design and correct use, these pipes can effectively block sand particles, while allowing the continuous flow of oil and gas. This article explores the principle, key techniques, and application strategies of slotted pipes to ensure efficient and sustainable production.

Sand Prevention Principle in Slotted Pipes

Slotted pipes work by controlling the passage of sand through their specially designed slots. The slots allow particles of a certain size to flow with the oil, while larger particles are blocked outside the pipe. This process creates a "sand bridge" that stabilizes the reservoir and prevents sand from entering the wellbore.

Impact of Slot Design on Sand Control

The design of slot width is crucial to the success of sand control.

Slots that are too narrow: Can restrict the flow of oil and gas, affecting production efficiency.

Very wide slots: They can allow large particles to enter, damaging equipment and clogging the well.

Analysis of the particle size of the reservoir allows determining the optimal slot width, achieving a balance between sand control and efficient flow.

Slotted Pipe Sand Control Technique

Slotted pipe represents an essential technology in sand control by gravel packing, derived from the development of wrapped wire screen pipes. This method uses artificial gravel to create a bridge that blocks fine sand particles, allowing efficient oil and gas production. The process includes the use of slotted pipes, sand packing tools and accessories. Mud is injected into the annular space between the pipe and the formation, forming a stable filter layer.

Slotted Pipe Filtration Mechanism

In this technique, sand particles from the formation are blocked outside the pipe, while oil, gas or water flows through the narrow slots into the pipe. This highly efficient filtration mechanism makes slotted pipe an ideal solution for:

Openhole completions

Cased completions

Different types of wells, including vertical, inclined and horizontal wells.

Advantages of slotted pipes in mechanical sand control

Mechanical sand control is the most widely used method in oil fields, representing 80% of the techniques applied in wells with sand production. Slotted pipes stand out for:

Simple design and ease of installation: They are versatile and suitable for different well conditions.

High strength and durability: They withstand extreme conditions underground, such as high pressure and corrosion.

Low cost: Compared to chemical or composite technologies, they are more economical.

Balance between sand control and production capacity

In certain cases, allowing a moderate amount of sand production can improve production capacity. This helps prevent reservoir clogging, improves permeability and increases oil recovery. However, excessive sand control could reduce production, highlighting the importance of proper slot design.

Advanced Technologies to Improve Slotted Pipes

The development of new technologies has significantly improved the performance of slotted pipes:

High-precision slot cutting: Methods such as laser cutting achieve uniform and precise slots.

Innovative materials: Corrosion-resistant alloys extend the life of pipes.

Smart monitoring: Real-time systems optimize sand control and improve efficiency.

Maintenance and monitoring of slotted pipes

To ensure the long-term effectiveness of slotted pipes, regular maintenance and monitoring are essential:

Periodic cleaning: Prevents sand buildup that could clog slots.

Anti-corrosion treatment: Applying special coatings prolongs the life of pipes.

Data analysis: Monitoring production dynamics allows sand control strategies to be adjusted as needed.

Conclusion

Slotted casings are key tools for sand control in oil wells. Their proper design and application not only improve production efficiency but also extend the service life of the equipment. With the continuous advancement of sand control technologies, these pipes will play an even more prominent role in oilfield development in the future.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :