In oil drilling operations, screen casings are an important equipment, and are often used for early completion or oil production to prevent sand. At present, the most commonly used screen casings are wire-wound screen casings. The manufacturing method of this screen casing is: winding a certain cross-section of steel wire evenly distributed on the surrounding screen rods or on the metal liner with holes and welding it firmly, and leaving a certain gap as the screen hole. The screen casing is a separator used to separate liquid sand in oil and gas wells or water wells. Like the slotted casing, its main function is to prevent sand. Due to the geological conditions of the oil wells, different sand layers use different steel grades and types of pipes (slit, drilled, wire-wound, bridge type, composite) for oil exploitation. The screen casing complies with API 5CT specifications.

Features of oil screen casings:

1. The oil screen casing is processed with J55 or N80 oil casing pipe body, which has high strength and is not easy to deform

2. The verticality of the slit edge is good, the cutting edge is smooth, there is no burr, and the slit is uniform.

3. Large flow area, 27/8" screen casing has 300 slots/1.5m, flow area is 72 per cubic centimeter, which is 2.4 times larger than the flow area of the same specification oil pipe. It is conducive to liquid flow.

4. Its advantages are more obvious when used in inclined wells and horizontal wells.

5. Anti-corrosion treatment is carried out as a whole, and a dense protective layer is formed on each surface of the screen casing, which improves the corrosion resistance and wear resistance of the screen casing and can effectively extend its service life underground.

6. It is suitable for sand prevention in sand-producing wells with sand particle diameter greater than 0.3mm.

7. Simple operation, easy to use, large inner diameter, easy to configure pipe strings

The main body of the oil casing is used for processing, which has high strength and is not easy to deform; the edge verticality is good, the cutting edge is smooth and burr-free, and the cutting seams and holes are uniform; the flow area is large, which is much larger than the flow area of the oil casing of the same specification. It is conducive to the flow of liquid; it can be used in inclined wells and horizontal wells, and its superiority is more obvious; it can be treated with anti-corrosion as a whole, and a dense protective layer is formed on the surface of the screen, which improves the corrosion resistance and wear resistance of the screen, and can effectively extend its service life underground; it is suitable for sand prevention in sand-producing wells with sand particle diameter greater than 0.3mm; it is simple to operate, easy to use, with a large inner diameter, and easy to configure the pipe string.

Main specifications of screen casing

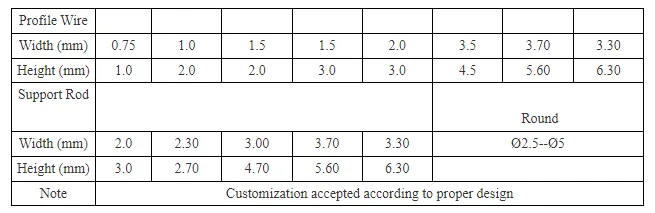

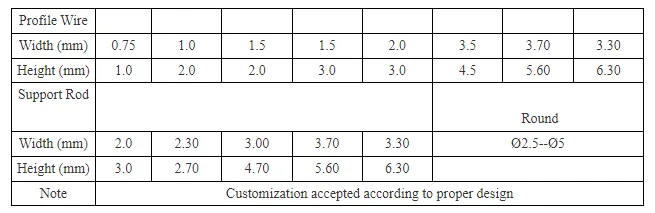

1. Wire winding specifications:

Wire width (mm): 1.50 1.80 2.30 3.00 3.30 3.70

Wire height (mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30

Common specifications

Diameter: 168mm, 219mm, 273mm, 325mm, 426mm,

Filtering accuracy: 0.1mm, 0.2mm, 0.5mm, 0.7mm, 1mm, 2mm;

Standard length: 2.925m/piece, 5.85m/piece

Tube head: welded tube head, spiral tube head

2. Support bar specifications:

Wire width (mm): 2.30 3.00 3.30 3.70

Wire height (mm): 2.70 3.60 4.70 5.60 6.30

Round wire: from 2.50mm to 6.0mm

Can also be produced according to customer needs

Minimum gap: 0.1mm

Connection method: welding and threaded connection.

Standard length: 3m/5.85m.

Continue to design and manufacture stainless steel screens from 0.7m (2ft) to 12.2m (40ft)

3. Technical parameters

Gap (mm): 0.02, 0.025, 0.03, 0.04, 0.05, 0.06, 0.08, 0.10, 0.15, 0.2, 0.25, 0.30-35, can also be made according to customer requirements

Material: low carbon steel, low carbon steel galvanized, plastic spray, stainless steel ( 304, 316L, 317, duplex stainless steel 2205, Hastelloy, etc.)

Length: 50mm--6000mm

Outer diameter: 20mm--800mm

Connection form: groove connection or threaded connection, direct pipe head or threaded pipe head

Screen wire specifications: conventional 0.75*1.5mm, 1*2mm, 2*3mm, 2.3*3mm, 3*5mm

Internal ribs: DN25mm/12 roots, DN33mm/8 roots, DN37mm/8 roots, DN40mm/10 roots, DN60mm/12 roots, etc.

Specifications of wire wrap and support strips for screen casing

The primary function of screen casings in oil drilling

The reason why it is called screen casing is that the primary function of this type of pipe in oil drilling is to select small stones or gravel in the oil, which can ensure the purity of the oil as much as possible. So what are the specific functions of oil test tubes?

1. Regeneration of old wells in oil fields: Since oil is a non-renewable resource, we must not only learn to save it, but also study the technology to make it reusable. At present, a considerable number of oil wells in major oil fields in the world have entered the middle and late stages of oil production, and the oil output is decreasing year by year. In order to tap the potential of old wells, the oil industry in all countries is trying to study and solve the problem of less and less oil output. Some owners have side-drilled horizontal wells, and extended other lower oil collection areas. Regardless of whether they want to, the common method adopted by owners is: side-drilling "horizontal wells", which are inseparable from oil screen casing.

2. New oil wells on land: Due to the different geographical structures and the distribution of oil and rock formations, or in order to reduce the number of wells and reduce pollution on the ground, most of the oil industry now adopts horizontal wells. One horizontal well can reduce many vertical wells, but it is still inevitable to use screen casings when drilling wells.

3. Offshore oil well drilling: Due to the rise of large-scale offshore oil exploitation in China and even the world, as well as the vigorous development of geothermal wells, brine wells and deep water wells, these all require screen casings with better quality as support.

4. Sand control of pumping pipes: Since the primary function of screen casing is to select sand and gravel from oil, they need to be used in conjunction with screen casings in casing or pumping pipes to ensure the purity of oil, otherwise the later purification process will become more troublesome.

Conclusion

screen casings play a vital role in oil drilling operations. Their high strength, large flow area, corrosion resistance and easy operation make them the first choice for well completion and sand control operations. Selecting the right specifications and types of screen casings can effectively improve oil production efficiency, ensure oil quality, and extend the life of underground work.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :