What is a

ductile iron pipe? As the name implies, ductile iron pipe is a type of cast iron pipe. In addition to ductile iron pipe, other cast iron pipe categories include gray cast iron pipe, cement cast iron pipe, etc. Ductile iron pipe refers to a water supply pipe formed by centrifugal casting after molten iron in blast furnace is spheroidized. Due to the spheroidization treatment, ductile iron pipe itself has good plasticity, toughness and mechanical properties. It is widely used in municipal pipe network, water supply pipe network and large-scale water conservancy projects. It is an advantageous pipe in the field of water supply.

1. Specifications and standards of ductile iron pipe

K9 grade ductile iron pipe, also known as national standard ductile iron pipe, is classified according to nominal diameter and is divided into Dn80-Dn2600.

China Ductile Iron Pipe Standard

GB/T 13295-2008 Ductile iron pipes, fittings and accessories for water and gas

pipelines

GB/T 13295-2003 Ductile iron pipes, fittings and accessories for water and gas pipelines

GB/T 17457-1998 General requirements for centrifugal cement mortar lining of ductile iron pipes

GB/T 17458-1998 Composition test of fresh mortar for centrifugal cement mortar lining of ductile iron pipes

GB/T 17459-1998 Asphalt coating of ductile iron pipes

GB/T 17456 Zinc spraying on the surface of ductile iron pipes

GB/T 17219-1998 Safety evaluation standard for drinking water transmission and distribution equipment and protective materials

International Standards for Ductile Iron Pipes

Ductile iron pipes follow several key international standards to ensure quality and performance:

1.ISO 2531

Global standard for ductile iron pipes, fittings, and joints for water and wastewater. It covers material specs, dimensions, mechanical properties, pressure ratings, coatings, and testing.

2.EN 545 & EN 598 (Europe)

EN 545: For water supply systems.

EN 598: For pressurized wastewater and sewage.

Both standards focus on durability, linings, pressure ratings, and mechanical testing.

3.AWWA C151 / ANSI A21.51 (USA)

North American standard for ductile iron water pipes. It includes size range (3"–64"), pressure classes, wall thickness, and cement-mortar lining.

4.BS 4772 (UK)

Former British standard for water and sewage pipes; still used in some legacy systems.

5.JIS G5526 (Japan)

Japanese standard detailing manufacturing and inspection for water supply ductile iron pipes.

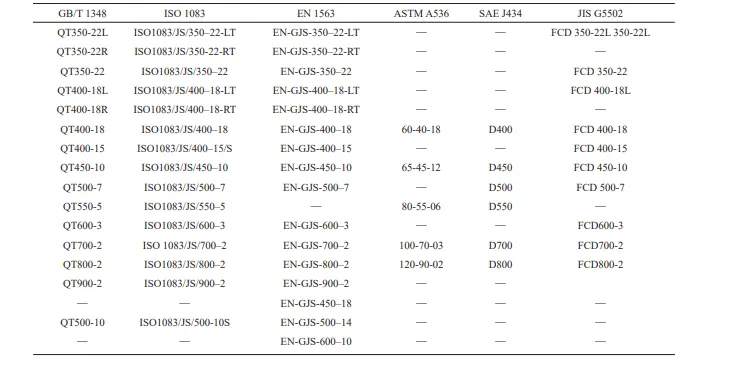

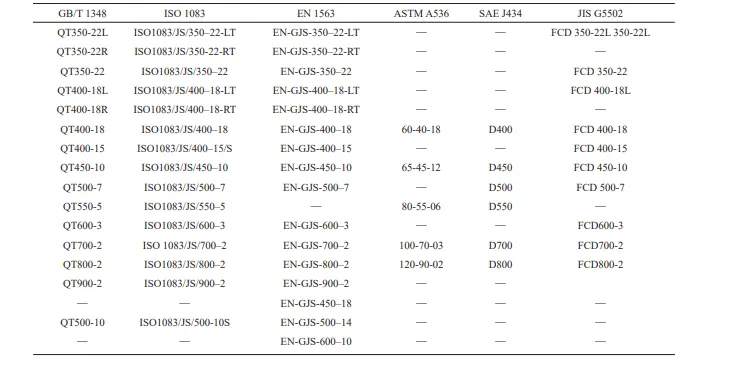

Grade Designations for Spheroidal Graphite Ductile Iron Pipes in Different Standards

The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. A certain amount of spheroidal graphite is distributed on the ferrite and pearlite matrix. The proportion of ferrite and pearlite in the matrix structure varies according to the nominal diameter and the requirements for elongation. The proportion of pearlite in small diameter is generally not more than 20%, and the proportion of large diameter is generally controlled at about 25%. Minimum tensile strength: 420/Mpa, minimum yield strength 300/Mpa, minimum elongation 7%. Ductile iron pipes are implemented in accordance with GB/T13295-2008 ISO2531/2008; 6 meters of ductile iron pipes for water supply.

2. Characteristics of ductile iron pipes

(1) Pressure bearing performance

Water supply pipes are usually buried underground and are inevitably affected by loads from the land and vehicles. Ductile iron pipes have the nature of iron and the properties of steel, which can ensure that the pipes can effectively resist external loads and are more economical to lay;

(2) Hydraulic performance

During peak water use, ductile iron pipes can withstand higher internal pressures; in addition, the inner lining of ductile iron pipes is smooth and uses cement mortar lining, with an equivalent roughness K value of 0.030 mm;

(3) Sealing performance

Ductile iron pipes use flexible interfaces. After rigorous sealing tests, they can effectively prevent various forms of penetration and erosion and significantly reduce the leakage rate of pipeline interfaces;

(4) Anti-corrosion performance

Cement mortar lining is often used for internal anti-corrosion of ductile iron pipes, and zinc spraying + asphalt spraying finishing layer is used for external anti-corrosion, which can effectively isolate the erosion of poor water quality and corrosive soil.

3. Production process of ductile iron pipe

Blast furnace molten iron - molten iron refining - spheroidizing treatment - core making - centrifugal casting - annealing furnace - ring cutting and rounding - zinc spraying - three grinding - water pressure detection - cement lining - cement curing - lining grinding - socket/pipe body painting - pipe body logo spraying - finished product storage

4. Comparison of ductile iron pipes with other water supply pipes

Compared with

stainless steel pipes, the interface of ductile iron pipes adopts flexible interface, low leakage rate, and can achieve the purpose of efficient water saving;

Compared with PE pipes, ductile iron pipes have a higher safety factor against internal pressure, better internal and external corrosion resistance, longer service life, lower installation difficulty, and are simpler and faster.

Cast iron pipes are also called cast iron drainage pipes, flexible earthquake-resistant cast iron drainage pipes, machine-made cast iron drainage pipes, flexible connection cast iron drainage pipes, and centrifugal cast iron drainage pipes. W-type flexible cast iron drainage pipe is a commonly used connection method in my country. It has the advantages of small radial size (no flange), easy layout, space saving, the length can be cut on site as needed, saving pipe materials, easy disassembly and assembly, and easy maintenance and replacement.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :