Drill collars are auxiliary equipment used at the bottom of the drill string and are key components of the drill tool assembly. The main features of drill collars are thick wall thickness and high gravity. The wall thickness is generally 38~53mm, which is equivalent to 4~6 times that of the drill pipe. Due to the special working environment, the drill collar exerts pressure on the drill bit during the rock breaking process and plays a leading role in straight hole drilling. It needs to have good rigidity.

What is API Spec 7-1

In oil and gas drilling projects, the stability and efficiency of the drill string system are crucial. As the main component in the drill string that bears the ballast and provides the drill bit down pressure, the quality and manufacturing standards of the drill collar directly affect the safety and reliability of the drilling process. API Spec 7-1 is an important technical standard established by the American Petroleum Institute for drill string components such as drill collars.

API Spec 7-1 is a technical specification specifically formulated for drill string components (such as drill collars, weighted drill pipes, square drill pipes, stabilizers, etc.), covering material selection, mechanical properties, heat treatment, non-destructive testing, dimensional accuracy, tolerance control and other aspects. Drill collars manufactured according to this standard are widely used in land and offshore drilling projects, especially for drilling operations in deep wells, high-pressure wells and complex formations.

API Spec 7-1 Drill Collar Manufacturing materials and processes

1. Conventional drill collar material: AISI 4145H alloy steel

Standard drill collars are usually made of AISI 4145H forged or fine-rolled alloy structural steel, which has excellent strength, toughness and hardness, and can meet the use requirements under high torque and high load conditions.

Type: hot-rolled or forged round steel

Heat treatment method: quenching + tempering

Brinell hardness (HBW): 285 - 341

Impact toughness: Charpy V-notch test at 20℃±5℃, 1 inch deep from the outer surface, impact energy ≥ 40 ft-lb (about 54J)

2. Heat treatment process

In order to ensure that the product has uniform and stable mechanical properties throughout the entire length, the drill collar must be heat treated throughout the length during the production process. The standard heat treatment process includes:

Uniform heating

Quenching (usually oil quenching)

Tempering (improving toughness and eliminating residual stress)

The heat-treated drill collar has high strength, high hardness, good bending and torsion resistance, and fully meets the performance requirements of API Spec 7-1.

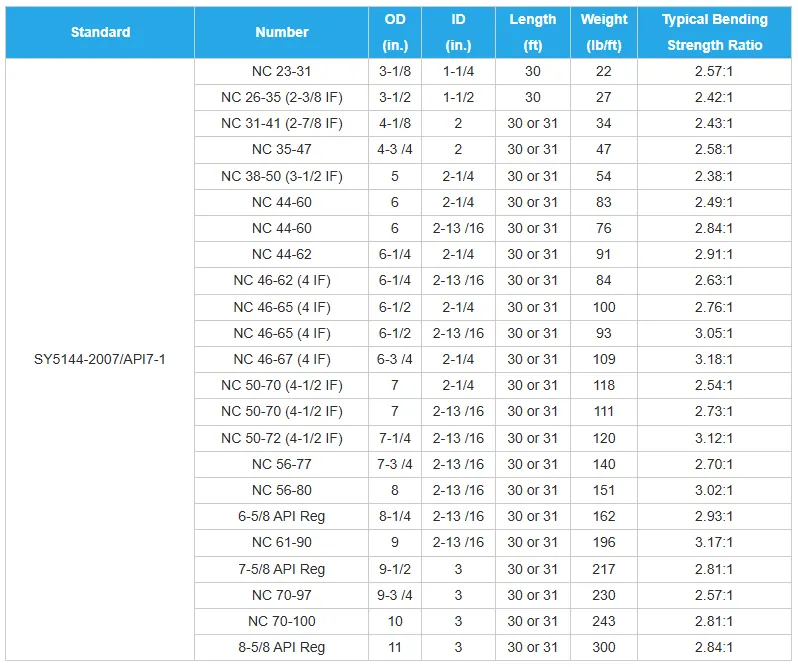

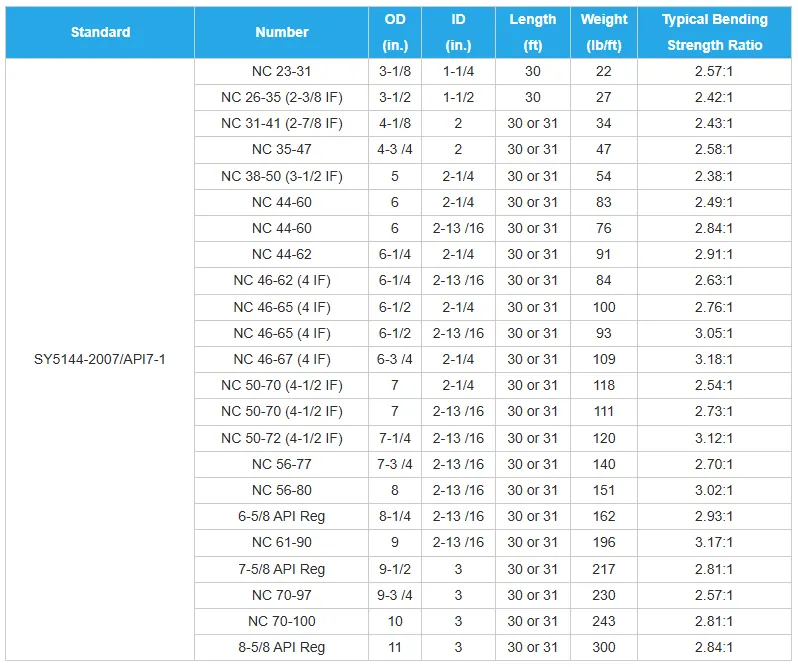

API Spec 7-1 Drill Collar Specifications:

API Spec 7-1 Drill Collar Structural design and interface type

Drill collars under API Spec 7-1 standard usually have the following structural designs:

Plain Drill Collar: used for conventional weighting;

Spiral Drill Collar: reduces the risk of differential pressure sticking and improves drilling efficiency;

Thickened joint design: enhances the strength of the connection and avoids breakage;

Connection thread types: NC31, NC38, NC50, REG, IF, etc., selected according to customer needs, with API standard thread lubrication treatment and thread protection sleeve.

Inspection and quality control

Drill collars manufactured according to API Spec 7-1 are subject to the following key quality inspections:

UT ultrasonic inspection: to detect internal defects

MT magnetic particle inspection: to detect surface cracks

Dimension inspection: to ensure that tolerances meet API requirements

Mechanical property inspection: including hardness, impact toughness, tensile strength testing, etc.

API Spec 7-1 Drill Collar represents high standards and high performance in drill string technology. Whether it is a conventional alloy drill collar or a high-end non-magnetic drill collar, its role in drilling operations is indispensable. Through strict material selection, standardized manufacturing processes and comprehensive testing methods, this type of product ensures the safety, stability and efficiency of the drilling process, and is an ideal choice for high-tech drilling projects such as deep wells, complex wells and directional wells.

If you need to customize drill pipes and drill collars or other steel pipes of different sizes, materials or interface types, please contact us for more technical information and quotation support.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :