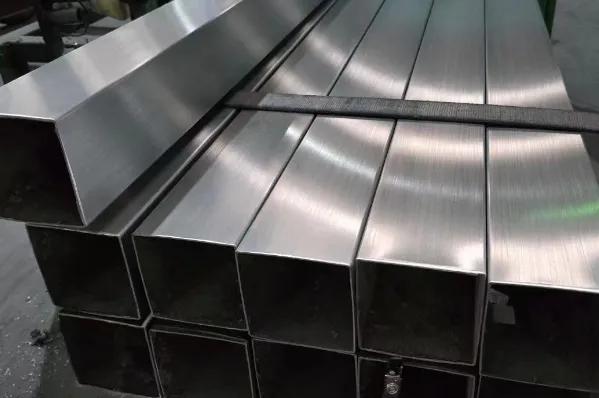

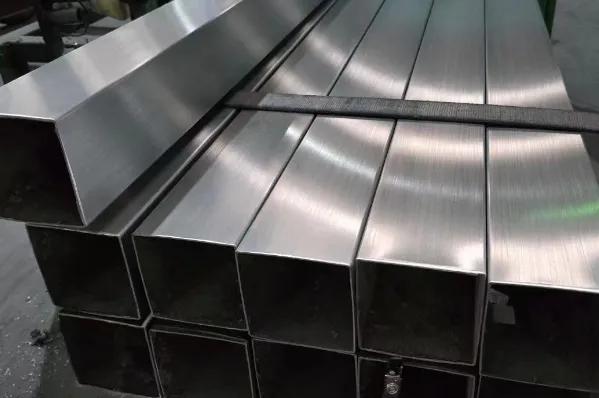

In practical applications, high strength indicates that the material is less prone to deformation and breakage (cracking) under static loads; it also typically exhibits good hardness and wear resistance. Therefore, materials requiring high hardness and wear resistance are typically made from high-strength materials. This article introduces the strength standards for 304 stainless steel

square tubes.

The Influence of Dimensions and Wall Thickness on the Strength of 304 Stainless Steel Square Tubes

The actual strength of 304 square tubes is not only determined by the material itself, but is also significantly influenced by the following factors:

1. Cross-sectional Dimensions (Width & Height)

Larger dimensions result in stronger bending and torsional resistance.

For example, a 40×40 square tube has a much stronger bending resistance than a 20×20 square tube.

2. Wall Thickness

Increasing wall thickness → increasing section modulus → significantly improving strength.

Common thicknesses:

0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm…

Increasing the wall thickness from 1.0mm to 2.0mm can increase the bending load-bearing capacity by 50-120%.

3. Weld Quality

304 square tubes are mostly welded tubes, making weld integrity extremely important.

A weld that meets the following criteria has a strength essentially equivalent to the base metal:

Complete fusion of weld metal

No cracks, porosity, or slag inclusions

Sufficient penetration on the back side

Poor welds will directly reduce load-bearing capacity.

Strength Standards for 304 Stainless Steel Square Tubes (Implementation Specifications)

The strength standards for 304 square tubes are mainly based on the following specifications:

(1) International Standards (Commonly used for export products)

ASTM A554 (Stainless steel welded structural tubes)

ASTM A312 (Stainless steel seamless tubes)

EN 10296-2 (Stainless steel tubes for structural purposes)

DIN 17455

(2) Chinese National Standards

GB/T 19228.1-2011 "Stainless steel welded tubes"

GB/T 14976 "Stainless steel seamless tubes for fluid transport"

GB/T 12771 "Welded stainless steel tubes for fluid transport"

What is the strength of 304 stainless steel square tubes?

The strength of a material is its ability to resist damage under external forces. When a material is subjected to external forces, internal stress is generated. As the external force increases, the stress increases accordingly until the bonding force between the material's internal particles is insufficient to resist the applied external force, at which point the material fails. The ultimate stress value reached at material failure is called the material's ultimate strength.

Based on ambient temperature, strength can be categorized as: room temperature strength (resistance to external forces at room temperature), and thermal (high temperature) or cold (low temperature) strength (resistance to external forces at high or low temperatures). Based on the nature of the external force, the main strengths include yield strength, tensile strength, compressive strength, and bending strength. In engineering, yield strength and tensile strength are commonly used; these two strength indicators can be measured through tensile testing.

Tensile strength refers to the maximum stress a material can withstand before fracture. When a 304 stainless steel square tube yields to a certain extent, its resistance to deformation increases again due to the rearrangement of its internal grains. At this point, although deformation develops rapidly, it can only increase with increasing stress until the stress reaches its maximum value. Afterward, the steel's resistance to deformation decreases significantly, and large plastic deformation occurs at the weakest point. The cross-section of the tube rapidly shrinks at this point, resulting in necking, until fracture. The maximum stress value before the steel fractures under tension is called the ultimate tensile strength or tensile strength.

Tensile strength of 304 stainless steel square tube: ≥515~1035 (MPa). Because tensile strength represents the maximum load-bearing capacity of an actual part under static tensile conditions, and is easy to measure with good reproducibility, it is one of the important mechanical property indicators of metallic materials in engineering, widely used in product specifications or quality control indicators.

Yield strength is the yield limit of a metallic material when it yields, that is, the stress that resists a small amount of plastic deformation. However, for metallic materials without a clear yield point, the stress value that produces 0.2% residual deformation is defined as its yield limit, called the conditional yield limit or yield strength. External forces exceeding this limit will cause permanent, irreversible failure of the component.

The conditional yield strength of 304 stainless steel square tubing is ≥205 MPa. The conditional yield strength is commonly used as an evaluation index for the mechanical properties of 304 stainless steel square tubing and represents the material's actual service limit. This is because necking occurs when the stress exceeds the material's yield limit, increasing strain and causing material failure, rendering it unusable.

The above are the strength standards for 304 stainless steel square tubing. The strength of stainless steel tubing is typically tested using yield strength and tensile strength. Yield strength reflects the material's resistance to deformation; tensile strength reflects the material's resistance to tensile failure.

For calculation formulas and notes, see “Square Tube Strength Calculation and Notes”.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :