Currently, there are many varieties of slotted casing used for limited sand control in the world, and there are no "API" or national or industry standards. Most of them adopt the production and inspection standards set by the company. For many years, many experts at home and abroad have been studying how to process and manufacture a slotted casing that is used for oil well and gas well completion, gravel filling and sand control, and to form certain oil well production strings. Because there are many manufacturing methods, it is easy to cause confusion in the market. It is understood that cutting, milling, drilling, beam and inlay methods are the most typical and most common methods. Each has its own application scope and field, the processing and production quality is different, and the drilling method is different. So far, an effective method has not been found to process and manufacture a slotted casing that is suitable for oil extraction and sand prevention, has a seam that can withstand high external forces, is not easily deformed and blocked, and has practical value.

With the rising market demand, coupled with the high difficulty of cutting slotted casing holes and the requirement for high precision in the geometric size and shape of the holes, technical difficulties have been set up for the seemingly simple casing and casing processing. It has increased the "economic" value, which has also attracted great attention from numerous related industries.

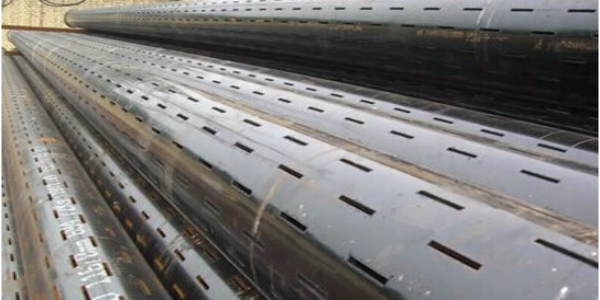

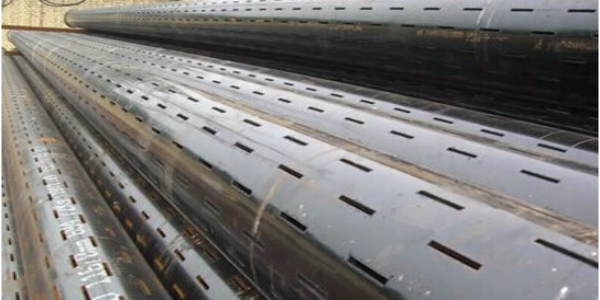

Trapezoidal slotted casing is to cut multiple longitudinal or transverse slits of a certain length on the oil pipe or casing in a certain way, and the cross-sections of these slits are trapezoidal, that is, the width of the slit on the outer surface of the pipe is smaller than the width of the inner slit. Surface seam width. For a longer pipe (usually the first 2 meters or more), multiple surface slits with a width of only 0.1mm or slightly wider must be cut on the pipe and the shape of the slits should be trapezoidal and extend toward the inner wall of the pipe. This kind of slotted casing The processing is very difficult, especially the V-shaped seam cut by two laser beams. Since the outer seam directly expands inward at a certain angle, the corner edge formed by the seam has little pressure and is easily blocked by the deformation and deformation of the debris flow. , and the application of laser cutting technology is complicated and the processing cost is relatively expensive, making it difficult to form industrial production.

Slotted casing is a special pipe body installed at the lower end of seamless steel pipes or welded steel well pipes in oil wells, water wells, geothermal wells, salt water wells, etc., to separate the mined liquid from the sand and gravel in the formation. Due to the basic structural characteristics of the strata involved, the different particle sizes of the sand and gravel in contact, and the differences in the viscosity of the mining liquid, the hole specifications and shapes of the required slotted casing are also different. In recent years, with the rapid development of the petroleum and geological mineral industries, the maturity of oil well drilling technology in desert areas, the intensification of mid- and late-stage development of oil fields, the rise of large-scale offshore oil production and the vigorous development of geothermal wells, salt water wells, and deep water wells , the consumption demand for slotted casing continues to increase. The traditional drilling process of drilling a well, running casing, blasting and perforating can no longer meet the needs of modern drilling technology with complex terrain, high efficiency and high recovery rate. Slotted casing have been widely used in underground liquid drilling in the mining industry.

Slotted casing is widely used in the regeneration of old wells in oil exploration, new oil wells and exploration (test) wells, offshore oil production wells and pumping pipes, and is used in horizontal wells, sidetracking wells, radial branch wells or open hole gravel filling development. The well is completed with grooved casing for limited sand control. In people's daily life, geothermal wells, salt water wells, drought wells and domestic water wells also use slotted casings for limited sand control. Generally, vertical shafts use circular slot (hole) slotted casing instead of blasting and perforating to avoid many troubles caused by ejection holes. For this reason, it is also widely used at home and abroad. A quote from a petroleum expert can best describe the function of its slotted casing, which is to "separate the honey from the honey mixed with white sugar."

Nowadays, many types of slotted casing have been developed according to market demand. If classified by processing methods, they can be divided into hot-processed slotted casing and cold-processed slotted casing. Thermal processing is divided into: laser cutting and flame thermal cutting; cold processing is divided into: blade, ceramic blade cutting and drilling machine drilling, etc. If classified according to the cutting section of slotted casing, it can be divided into rectangular, trapezoidal, and special shape (round hole). If classified by the pipe body seam layout structure, it can be divided into straight row (parallel), staggered seam bridge seam, bridge type staggered seam and spiral seam, etc. If classified by structure, it can be divided into cutting casing (including cold processed pipe) , Assembling casing and wire-wound casing. According to the above economic and technical comparison, the development trend of slotted casing should be to vigorously use laser cutting slotted casing and milling blade to cut slotted casing and screen tube. The development trend of ordinary slotted casing (low alloy steel) pipes with a seam width of more than 0.5mm (including high-chromium pipe bodies) should be to cut slotted casing with a milling blade.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :