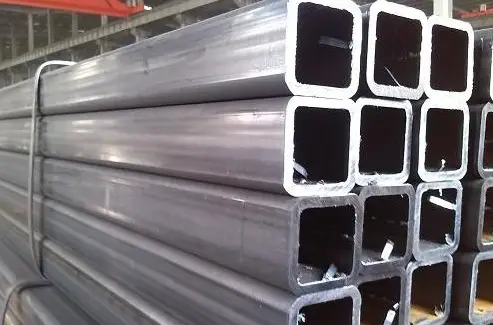

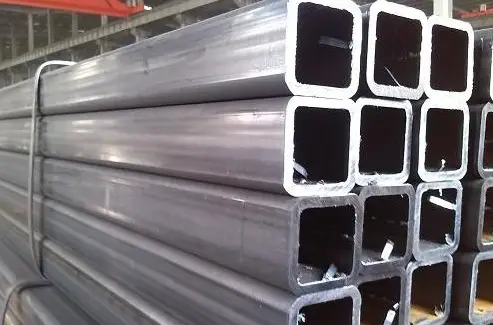

What is a square tube?

Square tube and rectangular tube are two commonly used steel pipe materials in construction projects. Square tube is a commonly used building material and is widely used in building structures. However, in order to ensure the quality and safety performance of square tubes, quality inspection of square tubes is essential. So what standards and specifications does square tube inspection follow? Let's take a look.

What standards and specifications are used for square tube inspection?

The quality inspection of square tubes is based on the national standards "Welded Steel Tube Inspection Standard" GB/T3092-1993, GB/T6728-2002 and GB/T13793-2008. Among them, GB/T3092-1993 is the standard for general requirements and test methods for welded steel tubes, GB/T6728-2002 is the standard for cold-rolled welded steel tubes for mechanical structures, and GB/T13793-2008 is the standard for conventional sequence straight seam electric resistance welded steel tubes and heads.

Square tube inspection includes inspections of appearance quality, dimensional deviation, curvature, torsion, bending performance, etc. Among them, appearance quality mainly inspects whether there are defects such as grooves, cracks, burrs and collapse on the surface of the square tube. Dimensional deviation mainly inspects whether the outer diameter, inner diameter, wall thickness and length of the square tube meet the standard requirements. Curvature mainly inspects the degree of curvature of the curve formed by the square tube during the bending process, as well as whether there is damage and obvious plastic deformation. The twisting degree mainly tests the deformation degree of the square tube after twisting, and whether there is damage and obvious plastic deformation. The bending performance mainly tests the deformation capacity of the square tube during the bending process and the residual deformation after deformation.

Quality requirements for square tubes

To meet industry demands, square tubes must adhere to specific quality requirements, including:

1. Material composition

The raw materials used for square tubes are usually carbon steel, alloy steel, or stainless steel. Common grades include Q235, Q345 (China), A36, A500 (USA), S235, S275 (Europe), and SS400 (Japan). These materials must meet strict chemical composition and mechanical property requirements.

2. Dimensional accuracy

Accurate dimensions are essential for structural stability. The outer dimensions, wall thickness, and straightness of the square tube must meet the specified tolerances. Deviations affect assembly and load-bearing capacity.

3. Mechanical properties

Square tubes must have sufficient tensile strength, yield strength, and elongation to withstand mechanical stress. For example, ASTM A500 requires a minimum yield strength of 46 ksi (317 MPa) for Grade B tubes.

4. Surface quality

The surface must be smooth and free of defects such as cracks, rust, or scale. Galvanized square tubes should have a uniform coating thickness to enhance corrosion resistance.

5 Welding quality

For welded square tubes, the seams must be free of visible defects, with strong fusion and penetration. Common welding methods include electric resistance welding (ERW) and submerged arc welding (SAW).

6 Corrosion resistance

Square tubes used in harsh environments (such as marine or oil and gas applications) require additional anti-corrosion treatments such as galvanizing, epoxy coatings, or corrosion-resistant alloys.

The quality requirements of square pipes are the key to ensuring good performance and reliable quality of square pipes during use. By strictly controlling the quality requirements in terms of materials, dimensions, appearance, chemical composition and mechanical properties, we can ensure that the quality of square tubes meets relevant standards and specifications and meets the needs of users. The quality requirements of square tubes are an indispensable part of the production and application of square tubes and the basis for the continuous development of the square tube industry. Our company produces high-quality square tubes through strict quality requirements to provide users with better products and services.

Square tube inspection standards

1) Marking and packaging inspection: The product should have a mark indicating the production direction or installation direction, and should indicate the factory name, trademark, product mark, color, batch number and production date. Each batch of products should have a certificate of conformity and a packing list. The certificate of conformity should contain the following contents: company name; product name; product specifications; production batch number; inspection results and inspection department seal. The packing list should contain the following contents: company name; product name, color; product mark; production batch number; product quantity; packaging date.

2) Appearance: There should be no bubbles, cracks, scars, cracks and inclusions on the surface, and no delamination; the surface is allowed to have the following defects within half of the thickness tolerance and not greater than the minimum thickness of the square tube: slight pitting and local deep pitting, small bubbles, small cracks and scratches, slight scratches and roller indentations. Local blue oxidation color is allowed.

3) Dimensions and allowable deviations: According to the supplier's technical documents, quality certification documents GB/T 702-2008

Square tube implementation standards

GB/T6728-2002, GB/T6725-2002, GBT3094-2000, JG 178-2005,

ASTM A500 JIS G3466, EN10210 or technical agreement.

GB/T3094-2000 (National Standard) Cold-pressed special-shaped rectangular tubes

GB/T6728-2002 (National Standard) Cold-bent

hollow steel for structure

ASTM A500 (American Standard) Carbon steel cold-formed circular section and special-shaped section welded rectangular tubes and seamless rectangular tubes for structure

EN10219-1-2006 (European Standard) Cold-formed welded hollow structural profiles of non-alloy and fine grains

JIS G 3466 (Japanese Standard) Angle rectangular tubes for general construction

Square tube standards define the size, material and technical requirements for different applications. Common standards include GB/T 3091-2008 (galvanized pipe), GB/T 6728-2002 (structural pipe), ASTM A500 (US structural pipe), EN 10219 (European cold-bent pipe), JIS G 3466 (Japanese structural pipe) and

API 5L (oil and gas pipeline). Sizes and materials vary to ensure strength, weldability and corrosion resistance.

How to detect the quality standard of square tube welding

1. After welding, the weld should be tested for hot hardness, and the evaluation standard is that the hot hardness of the weld does not exceed 100 of the hardness of the parent material itself.

2. When checking the internal quality of the weld, ultrasonic or irradiation can be used, and the outer surface of the weld can be inspected by magnetic powder or penetrant and magnetic powder or penetrant. After welding, it is necessary to thoroughly cool and keep warm. No matter what test method is used, it must meet the relevant requirements of the standard specification.

3. Check whether the appearance of the square tube weld meets the relevant requirements of the standard specification. At the same time, after each weld and heat treatment is completed, the weld should be inspected with a spectrometer to see if its chemical composition meets the relevant requirements. If not, the cause should be promptly identified and measures should be taken to deal with it.

In the building materials industry, the development of various pipes is different. Because of their different characteristics, there is a certain distance between the pipes. Square pipe is one of the many pipes in the building materials industry. It is formed by processing strip steel. Everyone needs to understand the various characteristics of steel pipes, but in the building materials industry, the development of various pipes is different. Due to their different characteristics, there is a certain distance between the pipes.

How to store square tubes?

Square tubes are one of the many pipes in the building materials industry. They are made of strip steel after processing. The various characteristics of steel tubes need to be understood by everyone, but because of the relationship between steel tubes and other raw materials, the storage of steel tubes requires specific conditions.

When storing square tubes, we first need to choose a suitable place. We need to consider many external factors, the corrosiveness of steel tubes, etc., so the place must be clean, dry and ventilated. Where harmful gases appear, Q235B square tubes cannot appear. Weeds and other debris should be removed in time to keep the outer surface of the steel clean. If there are acids, alkalis, salts, etc. in the warehouse, it is easy to react with the steel pipe and corrode the steel pipe, so try to cut it apart and don't let it touch. In addition, if it is for those metal products with higher prices, you can consider putting them in the warehouse for a good preservation. According to geographical conditions, there are sealed warehouses, but the ventilation settings are excellent.

At BAOWI Steel, we manufacture premium-quality square tubes that meet international standards and undergo strict quality control. Whether you need structural, mechanical, or precision square tubing, our advanced production processes ensure durability, strength, and reliability. Contact us today to get the best solutions for your projects!

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :