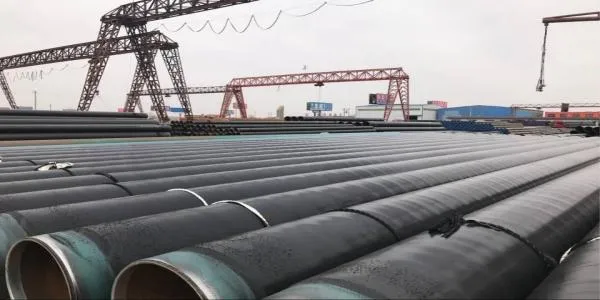

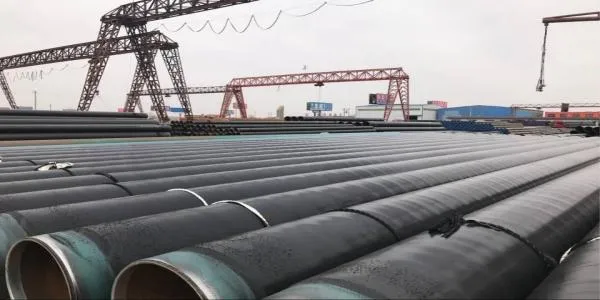

Oil steel casing pipe is an important equipment for oil drilling. Its main equipment also includes drill pipes, core pipes and casings, drill collars and small-diameter drilling steel pipes. Each well uses several layers of casing based on different drilling depths and geological conditions. Cement must be used to cement the casing pipe after it is lowered into the well. Unlike oil pipes and drill pipes, it cannot be reused and is a one-time consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes. According to the usage, casing can be divided into: conduit, surface casing, technical casing and oil layer casing, and their structures in oil wells. Casing is a steel pipe that supports the walls of oil and gas wells.

Guide sleeve: Mainly used for facilities in oceans and deserts to separate seawater and sand to ensure smooth operation. The main specifications of this sleeve are: $762m (30in)x25.4mm, $762m (30in)x19. 06mm.

Surface casing pipe: Mainly used for the first drilling, drilling through the soft surface strata to the bedrock. In order to seal this part of the stratum from collapse, it needs to be sealed with surface casing. The main specifications of surface casing are: 508m (20in), 406.4mn (16in), 339.73m (13-3/8in), 273.05m (10-3/4in), 24.48mm (9-5/9in), etc. The depth of down pipe depends on the depth of soft stratum, generally 801500m. The external pressure and internal pressure it withstands are not large, and K55 steel grade or N80 steel grade is generally used.

Technical casing pipe: Also called intermediate casing pipe, it is one or two layers of casing pipe in the middle of the casing program cover. Technical casing is used in the drilling process of complex formations. When encountering complex areas such as collapse layers, oil layers, gas layers, water layers, lost circulation layers, salt-gypsum layers, etc., technical casing needs to be installed for sealing, otherwise drilling will be difficult. Unable to proceed. Some wells have deep and complex formations, and the current well depth is several thousand meters. Such deep wells require several layers of technical casing, which require very high mechanical properties and sealing properties, and the steel grades used are also higher, except for 855. more N0 and P110 steel grades are used, and some deep wells also use Q125 or even higher non-API steel grades such as V150.

Oil layer casing pipe: When drilling reaches the target layer (layer containing oil and gas), the oil layer casing is used to completely seal the oil and gas layer and the upper exposed strata. The inside of the oil layer casing is the oil layer. Oil layer casing has the deepest depth among all types of casing pipe, and its mechanical properties and sealing performance requirements are also the highest. The steel grades used include K55, N80, P10, Q125, V150, etc. The main specifications of oil layer casing are: 177.8m (7in), 168.28m (6-5/8in), 139.7m (5-1/2in), 127mm (5in), 114.3mm (4-1/2in), etc.

Oil steel casing pipe is the lifeline to maintain the operation of oil wells. Due to different geological conditions, the state of stress in the well is complex. Tension, compression, bending, and torsion stresses act comprehensively on the pipe body, which places higher requirements on the quality of the casing itself. Once the casing itself is damaged for some reason, It may lead to a reduction in production or even scrapping of the entire well, so it is crucial to choose a good casing. Our company adheres to the principle of quality first, strictly controls every production level, and provides customers with high-quality products. If you If you have any needs, please feel free to submit an inquiry at any time.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :