The development history of stainless steel flanges

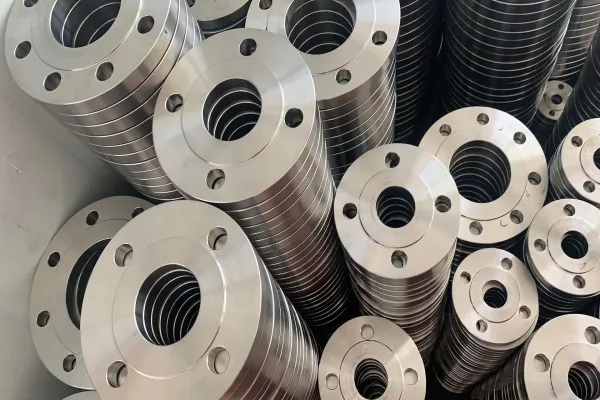

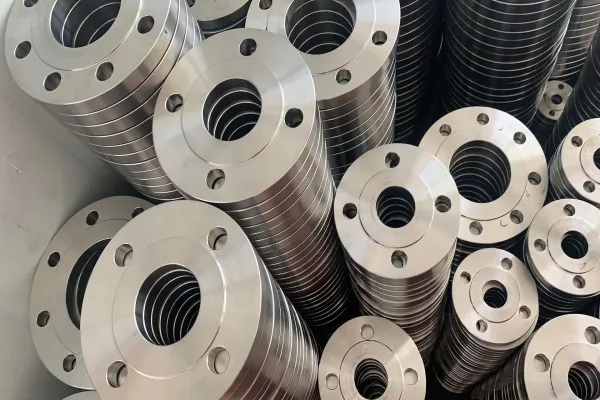

Stainless steel flanges are actually not difficult to understand. Stainless steel flanges are one of the flanges. Stainless steel flanges originated in the 1980s and are an emerging industry. After more than 20 years of development and exploration, it has now taken shape. Stainless steel flanges are a type of

pipe fittings, mainly made of stainless steel. With the development of the economy, the application range of stainless steel flanges is becoming wider and wider. Stainless steel flanges are flanges made of stainless steel materials with good corrosion resistance and good forming performance.

Stainless steel flange connections are very convenient to use and can withstand relatively large pressures. In industrial stainless steel pipes, flange connections are widely used. In the home, the pipe diameter is small and the pressure is low, and the flange connection is invisible. If you are in a boiler room or production site, there are pipes and equipment connected by flanges everywhere.

Stainless steel flanges composition

Stainless steel flanges consist of two interconnected annular parts, which are bolted together. These two annular parts are called flanges, and there are holes on the flanges. Bolts connect the two flanges tightly, and gaskets are used to seal between the flanges to connect the pipes. The design and structure of stainless steel flanges can be adjusted according to different needs to meet the requirements of different pipeline systems.

Stainless steel flange pipe fittings refer to pipe fittings with flanges. They can be cast, threaded or welded. Flange connection consists of a pair of flanges, a gasket and some bolts and nuts. The gasket is placed between the sealing surfaces of the two flanges. After tightening the nuts, the gasket surface deforms after the specific pressure reaches a certain value, and fills the uneven parts on the sealing surface to make the connection tight and leak-proof. Some pipe fittings and equipment already have flanges, which also belong to flange connections. Flange connection is an important connection method for stainless steel pipeline construction.

The role of Stainless steel flanges:

1. Connecting pipelines: Stainless steel flanges can connect two pipelines in the same system to ensure the smooth passage of fluids.

2. Connecting equipment: Stainless steel flanges can be used to connect pipelines and equipment, such as water pumps, storage tanks, compressors, conveyor belts, etc.

3. Adjusting pipelines: Stainless steel flanges adjust pipeline flow or pressure by installing larger or smaller flanges.

4. Easy operation: Stainless steel flanges can be easily installed and removed, making it easier to inspect or replace pipes or equipment.

5. Prevent leakage: Stainless steel flanges can keep the pipe sealed by tightening the bolts to prevent fluid/gas leakage.

6. Corrosion resistance: Stainless steel flanges have excellent corrosion resistance and can be used in humid and acidic environments to ensure the durability of the pipeline system.

What materials are stainless steel flanges made of?

Stainless steel flanges are available in 5 materials: 316 stainless steel (CF8M), 347 stainless steel (CF8C), 304 stainless steel (CF8), 304L stainless steel (CF3), and 316L stainless steel (CF3M).

316 stainless steel (CF8M): corrosive or ultra-low temperature or high temperature non-corrosive applications; temperature range: -268℃ to +649℃, temperatures above +425℃ must specify a carbon content of 0.04% and above.

347 stainless steel (CF8C): mainly used for high temperature, corrosive applications; temperature range: -268℃ to +649℃, temperature above +540℃ must specify carbon content of 0.04% and above.

304 stainless steel (CF8): corrosive or ultra-low temperature or high temperature non-corrosive applications; temperature range: -268℃ to +649℃, temperature above +425℃ must specify carbon content of 0.04% and above.

304L stainless steel (CF3): corrosive and non-corrosive applications, temperature range: up to +425℃.

316L stainless steel (CF3M): corrosive or non-corrosive applications, temperature range: up to +454℃.

Note: The above 5 stainless steel materials correspond to ASTM A351, CF8M, CF8C, CF8, CF3, CF3M all represent castings, commonly used in valve materials.

Stainless steel flanges have good metal properties and strong corrosion resistance. They are often used in steel structures, such as stainless steel flanges. Stainless steel flanges are also called stainless acid-resistant steel flanges. Their metal surface is smooth and not easily oxidized by air, so they are often used in high-pressure water pipes and corrosive pressure pipes. Here I share with you the excellent performance of stainless steel flanges.

First of all, as a metal material, it will react with air in a humid environment, thereby changing the original metal properties. However, stainless steel flanges can be passivated with oxidants to form a tough and dense chromium-rich oxide protective film Cr2O3 on the surface. Stainless steel flanges effectively prevent further oxidation reactions. Other metal pipes, such as galvanized water pipes and copper pipes, have very little passivation ability. This is the key reason why the corrosion resistance of galvanized copper pipes is far inferior to that of stainless steel pipes.

Then the wear and corrosion resistance of stainless steel flanges. Stainless steel flanges will not corrode uniformly like carbon steel, and no protective coating is required when used; stainless steel flanges use stainless steel flange water pipes, which have no restrictions on the chemical composition of water, because stainless steel has good corrosion resistance in water with various oxygen contents, temperatures, PH and hardness; stainless steel water pipes can withstand very high flow rates, even if the flow rate is greater than 40 m/s, it still maintains an extremely low corrosion rate, not exceeding 0.003 mm/year, which is particularly suitable for high-rise water supply. The thermal expansion coefficient of stainless steel flange pipes is similar to that of copper pipes, which is 1.5 times that of ordinary steel pipes. In comparison, stainless steel flanges have the characteristics of slow thermal expansion and contraction. In addition, stainless steel flanges generally undergo chemical reactions as a whole, forming a protective film on their surface, which is something that other metal materials cannot do.

In summary, stainless steel flanges are an important pipeline connector with good corrosion resistance, strength and durability. It is widely used in various industrial fields, and the working conditions and requirements of the pipeline system need to be considered during design and selection. By properly selecting and using stainless steel flanges, the stability, safety and reliability of the

pipeline system can be ensured.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :