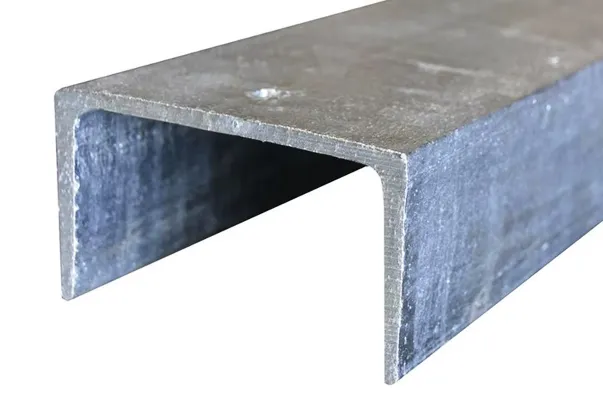

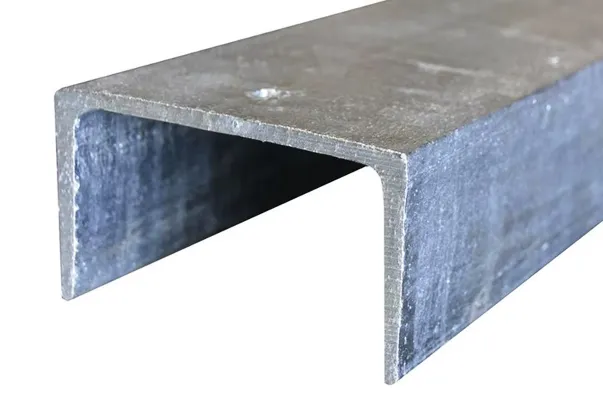

What is the C- Channel Steel?

C channel steel, also called C-beam or channel steel, is a structural steel component featuring a cross-section shaped like the letter “C.” It is commonly produced using hot-rolled steel and is known for its broad, flat surface with two right-angled

flanges on each side. The outer borders are typically angled, and the corners are slightly rounded, improving structural strength and resistance to stress.

The term "C channel" refers to the profile of the rolled steel, which resembles a squared-off “C.” This shape may start as a U-channel, and by adding flanges or bending them inward, it becomes a C-channel or a crimped C-channel, depending on the application.

Characteristics and Variations of C-Channel Steel

C-channel steel is available in a wide variety of sizes, thicknesses, and configurations, making it adaptable to different structural needs. Some variations even come pre-drilled with holes for bolting, while others feature short, inward-facing edges at the tips of the flanges for additional strength.

A common type is A36 hot-rolled steel C-channel, also known as American Standard Channels. These have a blue-grey rough finish, a flange slope of around 16-2/3%, and at least one non-length dimension exceeding 3 inches. They follow ASTM A36 / A36M-08, the standard for carbon structural steel.

Where is C-Channel Steel Used?

C-channel steel is highly versatile and widely used in multiple industries. Below are the most common applications:

Bridge Deck Supports: Offers durability and the ability to handle heavy loads and vibrations.

Heavy Machinery Framework: Its ability to flex without breaking makes it superior to stiffer I-beams and H-beams in some contexts.

Structural Supports: Ideal for trailers, construction equipment, and architectural elements such as frames and lintels.

Outdoor Infrastructure: Its corrosion-resistant variants—containing added nickel, copper, or chromium—make it suitable for light poles, towers, and marine environments.

Industrial Fabrication: A go-to material for equipment frames, racks, platforms, and support rails.

Compared to other structural products, C-channel steel is generally lighter and thinner, which makes it easy to handle while maintaining strength. However, it offers less flexibility than some hollow sections, so proper engineering evaluation is essential before use.

C-Channel Steel Chemical Composition

|

CHEMICAL COMPOSITION

|

|

Element

|

Percentage

|

|

C

|

0.26

|

|

Cu

|

0.2

|

|

Fe

|

99

|

|

Mn

|

0.75

|

|

P

|

0.04 max

|

|

S

|

0.05 max

|

Mechanical Information

|

Imperial

|

Metric

|

|

|

Density

|

0.282 lb/in3

|

7.8 g/cc

|

|

Ultimate Tensile Strength

|

58,000psi

|

400 MPa

|

|

Yield Tensile Strength

|

47,700psi

|

315 MPa

|

|

Shear Strength

|

43,500psi

|

300 MPa

|

|

Melting Point

|

2,590 - 2,670°F

|

1,420 - 1,460°C

|

|

Hardness Brinell

|

140

|

|

|

Production Method

|

Hot Rolled

|

|

C Channels Steel Specifications

|

Product name

|

channel steel,Channel Steels C Channel U Channel, Round bar/Angle bar

|

|

Standard

|

ASTM, BS, GB, JIS, EN, DIN

|

|

Grade

|

SS400, ST37-2, A36, S235JRG1,301L, 301, 410, 316L, 316, 321, 314, 304, 430, 304L, 317L, 904L

|

|

Product Keywords

|

U channel steel

|

|

manufacturing technique

|

Hot rolled(elementary) Can be processed again repeatedly

|

|

strength of extension

|

A36/420MPa S355JR/485MPa

|

|

Size

|

GB Steel channel 50*37*4.5-400*104*14.5

|

|

JIS Steel channel 75*40*3.8*7-152*76*6.4*9

|

|

EN Steel channel 140*60*7*10-200*75*8.5*11.5

|

How Is C-Channel Steel Manufactured?

The C-channel is produced through a streamlined process designed for strength and precision. Here are the key steps:

1. Cutting the Steel

Steel is first cut to the required size using heavy-duty cutting machines. Accuracy is essential to match structural specifications.

2. Hot-Rolling the Steel

The cut steel is heated to high temperatures to become malleable. It then passes through rollers to form the C shape. This hot-rolling method gives the channel its typical curved corners.

3. Cooling and Shaping

After shaping, the steel is cooled to retain its form and strength. Tools ensure the final dimensions are within standard tolerances.

4. Surface Coating

Finally, the C-channel is finished and coated—often

galvanized or painted—to protect it from rust and corrosion. It is then ready for use in construction or industrial projects.

Feature of C-Channel Steel

1.Representative type of Ferrite stainless steel, with magnetic

2.Good cost performance, price stability

3.Good shaping capability, weld bending capability, high thermal conductivity, low thermal expansion

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :