Definition and meaning of EN 10219

The EN 10219 standard is a European specification that specifies the technical delivery conditions for cold-formed

welded structural hollow sections made of non-alloy and fine grain steels. These hollow sections are widely used in the fields of construction, civil engineering, machinery and steel structures, and feature high strength, good weldability and a good strength-to-weight ratio.

If you are working with square tube,

rectangular tube or round hollow sections (CHS, RHS, SHS), especially in structural applications, understanding the EN 10219 standard is essential to ensure quality, compliance and performance.

Steel pipes exported to the EU require CE certification. How to obtain CE certification for hollow pipes such as steel pipes (round pipes, square pipes, rectangular pipes)? There are generally two requirements according to the use of steel pipes:

1. If it is a steel pipe material for pressure equipment, such as pipes for pressure pipes, it is necessary to apply for PED 4.3 metal material factory certification according to the requirements of the PED (2014/68/EU) Pressure Equipment Directive. Because steel pipes are also a common material for pressure equipment. After passing the PED 4.3 certification, the manufacturer of the steel pipe can issue EN10204 3.1 material certificate within the scope of the PED 4.3 certificate.

2. If the pipe is for construction purposes, it is necessary to apply for a CE certificate according to the requirements of the CPR (305/2011/EU) Building Materials Regulations. There are two main coordinated standards for hollow pipes in CPR: EN10210-1 and EN10219-1.

What Does EN 10219 Cover?

EN 10219 is composed of two main parts:

EN 10219-1: Technical delivery conditions

EN 10219-2: Tolerances, dimensions, and sectional properties

This standard specifies requirements for cold-formed structural hollow sections that are welded from hot-rolled or cold-rolled steel strip or plate, then shaped (usually by forming and welding) without further heat treatment (unless specified).

Materials Covered by EN 10219

The standard covers non-alloy and fine grain structural steels, such as:

S235JRH

S275J0H / S275J2H

S355J0H / S355J2H / S355NH

These grades differ primarily in their yield strength and impact test requirements. The suffixes J0H, J2H, and JRH refer to the impact energy absorbed at specific temperatures:

J0H: 27 J at 0°C

J2H: 27 J at -20°C

JRH: 27 J at 20°C (Room temperature)

Fine grain steels like S355J2H offer higher toughness and are often used in critical applications such as bridges, high-rise structures, and offshore platforms

EN10219-1 Scope of application:

EN 10219-1 specifies the technical requirements for cold-formed welding of round, square and rectangular tubes, and is applicable to hollow sections that are cold-formed or not heat-treated. It specifically specifies non-alloy high-quality steel, fine-grained non-alloy high-quality steel and fine-grained alloy special steel.

To summarize, in simple terms, EN10210-1 and EN10219-1 are both coordinated standards of the Construction Products Regulations (CPR). The corresponding steel pipes are generally used in construction. The difference is that EN10210-1 is suitable for hot-formed hollow pipes, while EN10219-1 is suitable for cold-formed hollow pipes that have not been heat-treated.

The EN 10219 specification outlines the technical delivery conditions for cold-formed welded structural hollow sections of circular, square tube, or rectangular forms. It applies specifically to sections that are cold-formed without subsequent heat treatment. This standard is significant for structural applications where hollow sections are used in building frameworks, bridges, and other engineering constructions, providing essential characteristics such as strength and impact resistance.

Classification of Steels in EN 10219

The EN 10219 classification system is similar to the classification in EN 10210, with the distinction being based on the type of steel and the specific properties required. The steels are classified into two main categories:

Non-alloy steels

Fine-grain steels

1. Non-alloy Steels

For non-alloy steel structural hollow sections, the designation includes several components:

EN 10219: Indicates the standard number.

S: Represents structural steel.

The minimum yield strength for thicknesses ≤16 mm, expressed in N/mm².

JR: Indicates impact properties at room temperature (27J minimum).

J: Refers to impact properties at specific temperatures (J0 or J2, indicating 0℃ or -20℃ impact resistance, respectively).

H: Denotes a hollow section.

Example: EN 10219 S275J0H

EN 10219: The European Standard.

S: Structural steel.

275: Minimum yield strength of 275 N/mm² (for thickness ≤16 mm).

J0: Impact resistance at 0℃ (27J minimum).

H: Hollow section.

2. Fine-grain Steels

For fine-grain steel structural hollow sections, the designation is structured similarly, but with more specific properties:

EN 10219: Indicates the European Standard number.

S: Structural steel.

The minimum yield strength for thickness ≤16 mm, expressed in N/mm².

N: Indicates normalized or normalized rolled feedstock material.

M: Indicates thermomechanically rolled feedstock material.

L: Specifies impact properties at -50℃.

H: Denotes a hollow section.

Example: EN 10219 S355NLH

EN 10219: The European Standard.

S: Structural steel.

355: Minimum yield strength of 355 N/mm² (for thickness ≤16 mm).

NL: Normalized fine grain steel feedstock, with impact properties at -50℃ (27J minimum).

EN 10219 Pipe dimensions and specifications tables

|

DN

|

O. D.

|

W. T.

|

|

Inch

|

mm

|

SCH5S

|

SCH10S

|

SCH10

|

SCH20

|

SCH30

|

SCH40

|

SCH60

|

SCH80

|

SCH100

|

SCH120

|

SCH140

|

SCH160

|

STD

|

XS

|

XXS

|

|

50

|

2″

|

60.3

|

1.65

|

2.77

|

–

|

–

|

–

|

3.91

|

–

|

5.54

|

–

|

–

|

–

|

8.74

|

3.91

|

5.54

|

11.07

|

|

65

|

2 1/2″

|

73

|

2.11

|

3.05

|

–

|

–

|

–

|

5.16

|

–

|

7.01

|

–

|

–

|

–

|

9.53

|

5.16

|

7.01

|

14.02

|

|

80

|

3″

|

88.9

|

2.11

|

3.05

|

–

|

–

|

–

|

5.49

|

–

|

7.62

|

–

|

–

|

–

|

11.13

|

5.49

|

7.52

|

15.24

|

|

90

|

3 1/2″

|

101.6

|

2.11

|

3.05

|

–

|

–

|

–

|

5.74

|

–

|

8.08

|

–

|

–

|

–

|

–

|

5.74

|

8.08

|

–

|

|

100

|

4″

|

114.3

|

2.11

|

3.05

|

–

|

–

|

–

|

6.02

|

–

|

8.58

|

–

|

11.13

|

–

|

13.49

|

6.02

|

8.56

|

17.12

|

|

125

|

5″

|

141.3

|

2.77

|

3.4

|

–

|

–

|

–

|

6.55

|

–

|

9.53

|

–

|

12.7

|

–

|

15.88

|

6.55

|

9.53

|

18.05

|

|

150

|

6″

|

168.3

|

2.77

|

3.4

|

–

|

–

|

–

|

7.11

|

–

|

10.97

|

–

|

14.27

|

–

|

18.26

|

7.11

|

10.97

|

21.95

|

|

200

|

8″

|

219.1

|

2.77

|

3.76

|

–

|

6.35

|

7.04

|

8.18

|

10.31

|

12.7

|

15.09

|

18.26

|

20.62

|

23.01

|

8.18

|

12.7

|

22.23

|

|

250

|

10″

|

273.1

|

3.4

|

4.19

|

–

|

6.35

|

7.8

|

9.27

|

12.7

|

15.09

|

18.26

|

21.44

|

25.4

|

28.58

|

9.27

|

12.7

|

25.4

|

|

300

|

12″

|

323.9

|

3.96

|

4.57

|

–

|

6.35

|

8.38

|

10.31

|

14.27

|

17.48

|

21.44

|

25.4

|

28.58

|

33.32

|

9.53

|

12.7

|

25.4

|

|

350

|

14″

|

355.5

|

3.96

|

4.78

|

6.35

|

7.92

|

9.53

|

11.13

|

15.09

|

19.05

|

23.83

|

27.79

|

31.75

|

35.71

|

9.53

|

12.7

|

–

|

|

400

|

16″

|

406.4

|

4.19

|

4.78

|

6.35

|

7.92

|

9.53

|

12.7

|

16.66

|

21.44

|

26.19

|

30.96

|

36.53

|

40.49

|

9.53

|

12.7

|

–

|

|

450

|

18″

|

457.2

|

4.19

|

4.78

|

6.35

|

7.92

|

11.13

|

14.27

|

19.05

|

23.83

|

39.36

|

34.93

|

39.67

|

45.24

|

–

|

–

|

–

|

|

500

|

20″

|

508

|

4.78

|

5.54

|

6.35

|

9.53

|

12.7

|

15.09

|

20.62

|

26.19

|

32.54

|

38.1

|

44.45

|

50.01

|

–

|

–

|

–

|

|

550

|

22″

|

558.8

|

4.78

|

5.54

|

6.35

|

9.53

|

12.7

|

–

|

22.23

|

28.58

|

34.93

|

41.28

|

47.63

|

53.98

|

–

|

–

|

–

|

|

600

|

24″

|

609.6

|

5.54

|

6.35

|

6.35

|

9.53

|

14.27

|

17.48

|

24.61

|

30.96

|

38.89

|

46.02

|

52.37

|

59.54

|

–

|

–

|

–

|

Common Steel Grades under EN 10219

EN 10219 specifies several steel grades, commonly used based on required strength and toughness. Examples include:

|

Grade

|

Description

|

|

S235JRH

|

Basic structural steel with impact testing at 20°C

|

|

S275J2H

|

Medium strength steel with -20°C impact performance

|

|

S355J2H

|

High strength with excellent toughness at low temperatures (-20°C)

|

The suffix “H” stands for hollow section, and the impact performance letters “J, JR, J0, J2” indicate the temperature at which the impact test is performed.

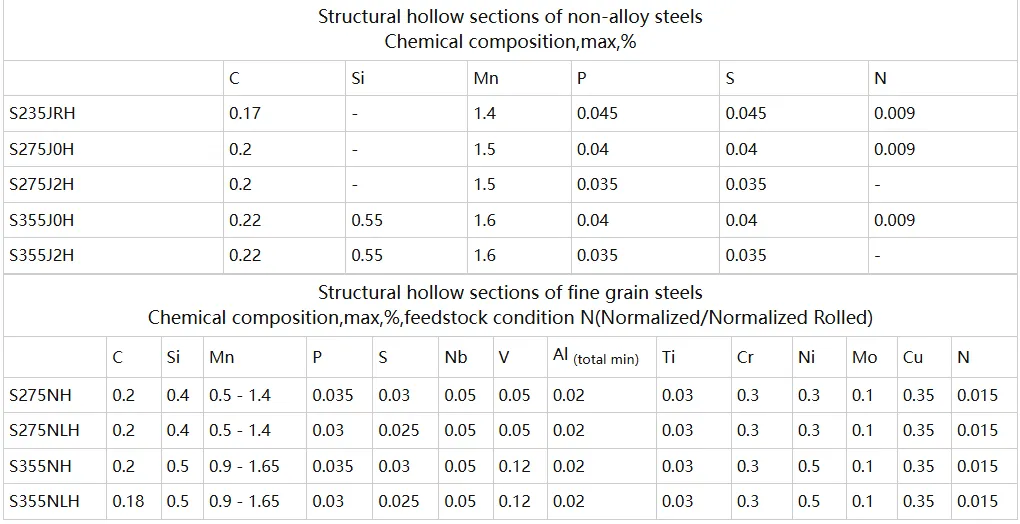

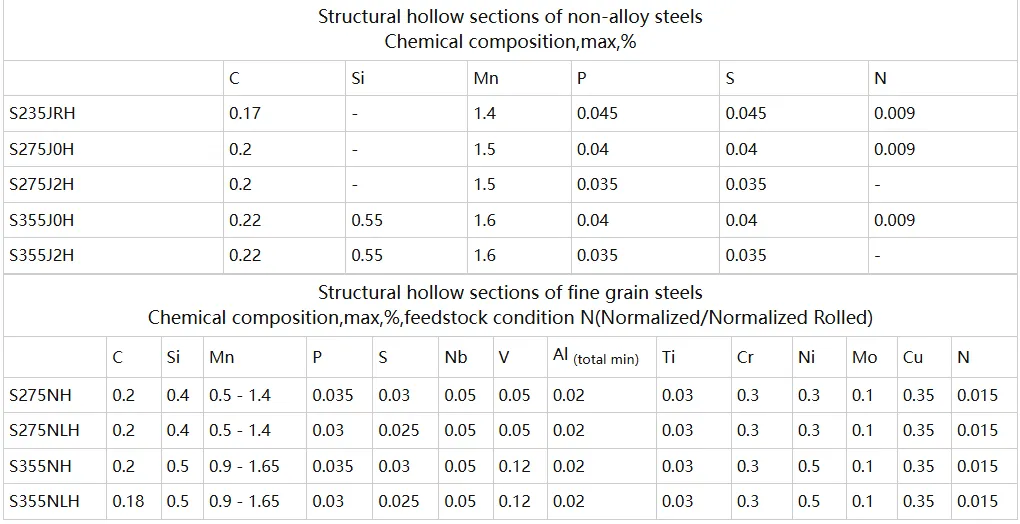

EN 10219 Requirements for chemical composition of pipes

Carbon (C): Higher carbon increases strength but can reduce ductility.

Manganese (Mn): Enhances strength and hardness.

Phosphorus (P) and Sulfur (S): Generally undesirable as they can reduce ductility and toughness, but their content is limited in these steel grades.

Nitrogen (N): Can improve strength but is controlled to avoid embrittlement.

The chemical composition may include trace amounts of alloying elements such as vanadium (V), titanium (Ti), and niobium (Nb), which help to refine the grain and improve the performance of the steel.

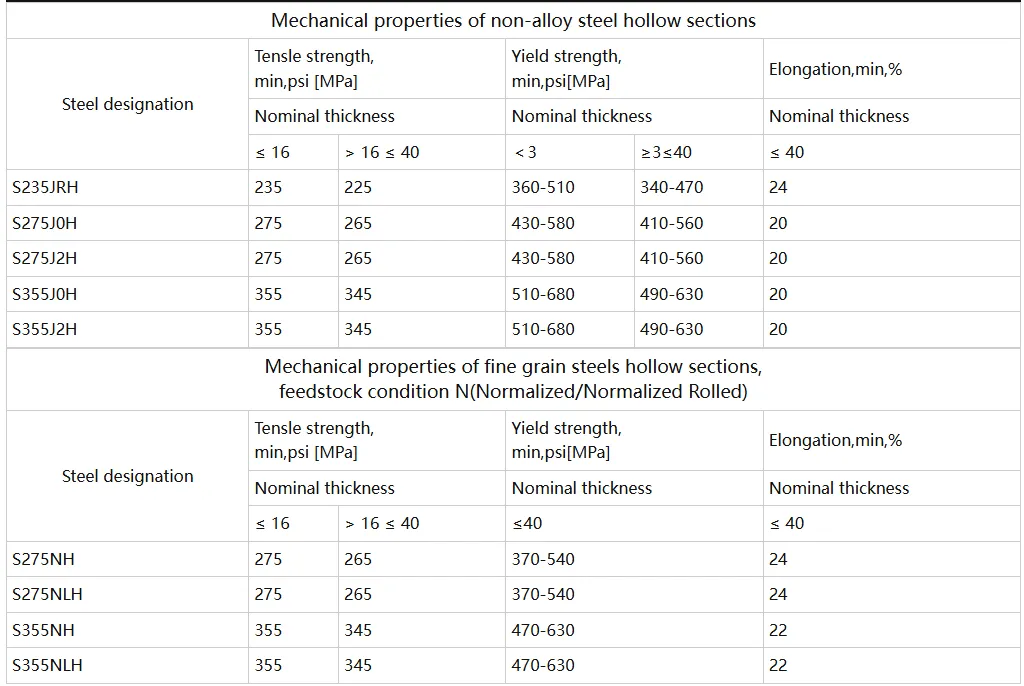

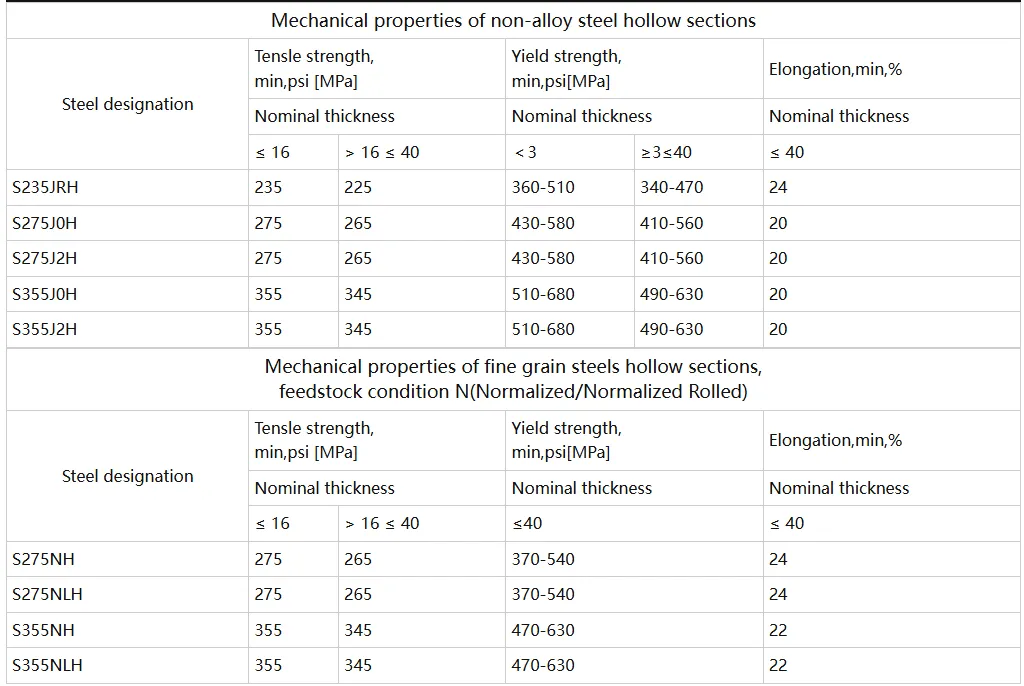

EN 10219 Mechanical properties tables for pipes

Strength: The S355 qrades have the highest yield and tensile strengths,making themsuitable for heavy-loadbearing structures. The s275 grades offer a balance between strength and ductility, while the S235JRH is the leaststrong but most ductile among them.

Ductility: The s235JRH has the highest elongation, indicating greater ductility compared to the other grades, which have a minimum elongation of 20%

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :