There are certain differences between tubing and casing in terms of size, structure and purpose. The size of tubing is relatively small, and it is mainly used to transport oil and gas, while the size of casing pipe is relatively large, and it is mainly used to fix the wellbore and isolate the formation. However, some pipes with the same specifications can be used interchangeably. At the same time, tubing and casing pipe also have a certain connection during use. They are both important components of the well and must be coordinated and cooperated with each other. At the same time, they must also cooperate and support with other accessories to ensure the safety and stability of drilling and production. This article will introduce the basic concepts and size specifications of tubing and casing in detail, and I hope it will be helpful to you.

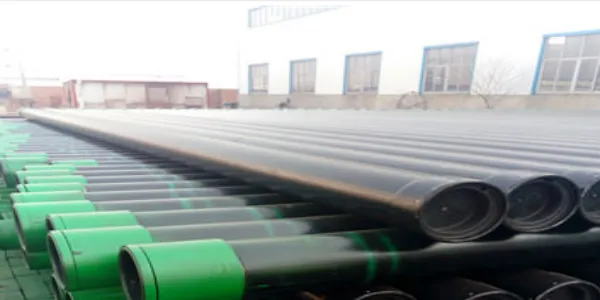

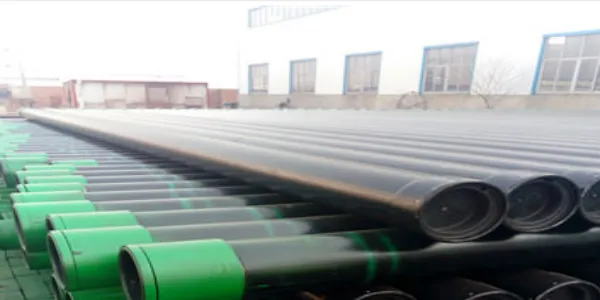

What is casing pipe?

API 5CT casing pipe is an indispensable and important material in the oil well drilling process. It is mainly used to support the oil and gas pipe wall to ensure the normal operation of the oil well during the drilling process and after completion. Each well needs to use several layers of casing pipe according to different drilling depths and geological conditions. casing pipe continues to play a role after cementing. Unlike reusable tubing and drill pipe, it is a disposable consumable material. Due to its one-time consumption characteristics, the consumption of casing pipe accounts for more than 70% of all oil well pipes. According to its use, casing pipe can be divided into surface casing pipe, intermediate casing pipe and production casing pipe. As the main structural component of the oil well, it is responsible for lining the wellbore, maintaining wellbore stability, preventing water and sand pollution, isolating the water layer from the production layer, and controlling the well pressure during drilling, production and well repair operations. casing pipe also provides a location for installing blowout preventers, wellhead equipment, production packers and production tubing.

Oil Country Tubular Goods

OCTG (Oil Country Tubular Goods) includes tubing, casing pip and drill pipe. The tubing is located inside the casing pipe and is a pipe used for the outflow of oil and natural gas. The tubing is usually connected in 30-foot (about 9-meter) sections with threads at both ends for easy installation. Its main function is to transport natural gas or crude oil from the production formation to the ground for processing. The production pipe is a simple section of the oil well pipe, usually connected in the same way, and is used to transport oil and gas from the production formation.

Common casing pipe sizes

Inner diameter 1mm-6.5mm, wall thickness 0.2mm-1mm, length 100mm-200mm: These casing pipes are often used in small-diameter applications and are suitable for delicate pipe projects.

Inner diameter 6.5mm-19mm, wall thickness 0.2mm-1.4mm, length 100mm-200mm: Medium-sized casing pipes are widely used in various pipe projects.

Inner diameter 19mm-200mm, wall thickness 0.5mm-2mm, length 100mm-200mm: These sizes of casings are suitable for large projects and more complex drilling operations.

Non-standard casing pipe sizes

Inner diameter 0.1mm-0.5mm, wall thickness 0.05mm-0.1mm, length 50mm-100mm: used in precision industrial and laboratory environments.

Inner diameter 200mm-500mm, wall thickness 2.5mm-5mm, length 200mm-500mm: suitable for special projects and projects with high strength requirements.

Other special dimensions: Customized according to customer needs, such as inner diameter, wall thickness and length can be flexibly adjusted to meet specific needs.

In mature water-flooded fields, a typical casing pipe string combination includes:

13-3/8-inch (340 mm) conductor

9-5/8-inch (244 mm) surface casing pipe

7-inch (178 mm) production casing pipe

For deeper, higher pressure wells, a typical casing pipe string combination might be:

16-inch (406 mm) conductor

13-3/8-inch (340 mm) surface casing pipe

9-5/8-inch (244 mm) intermediate casing pipe

7-inch (178 mm) production casing pipe

4-1/2-inch (114 mm) production casing pipe

How to choose the casing pipe size?

Choose the inner diameter and length of the casing pipe according to the required pipe diameter and length: Consider the specific needs of the project, choose the appropriate inner diameter and length to ensure the function and effect of the casing pipe.

Choose different wall thicknesses according to the pipeline environment and application: In different environments, the pipeline requires different wall thicknesses to ensure its durability and safety.

For casing pipes with special requirements, suitable materials should be selected: If high temperature resistance and corrosion resistance are required, appropriate materials should be selected to meet special application requirements.

Summary

As the main structural component of oil wells, the size and selection of casing pipes are crucial to the safety and stability of oil wells. Common and non-standard casing pipe sizes provide flexible options to meet different engineering needs. Typical casing combination strings have been widely verified in practical applications and are suitable for different geological conditions and well depths.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :