Stainless steel welded pipes are made by reacting molten metal with iron matrix to produce alloy layer, so that the matrix and coating are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot-dip galvanizing tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

In the welding quality standard of stainless steel pipe fittings, the lack of penetration defect is not allowed in double-sided welding or single-sided welding with pads. For single-sided welding without pads, the allowable lack of penetration defect is related to the importance of the weld. Important welds are not allowed to have single-sided lack of penetration; the depth of lack of penetration allowed in more important welds shall not exceed 10%-15% of the thickness of the parent material and shall not exceed 2M, and the length of lack of penetration shall not exceed the total length of slag inclusion allowed in welds of the same level; the depth of lack of penetration of general welds should be less than 20% of the thickness of the parent material and not more than 3mm, and the length should also be less than the total length of the allowed clamping edge. To control the size of the stainless steel pipe joint groove, thoroughly clean the weld root, and select the appropriate welding current and welding speed. For example, for a butt joint formed on one side and two sides, the gap between the two joints should generally be equal to the electrode diameter, and the blunt edge height should be about 1/2 of the electrode diameter.

Precautions for the use of stainless steel welded pipes

1. Generally, a power supply with vertical external characteristics is used, and positive polarity is used for DC.

2. Generally suitable for welding thin plates below 6mm, with beautiful weld formation and small welding deformation.

3. The shielding gas is argon with a purity of 99.99%. When the welding current is 50~50A, the argon flow rate is 8~0L/min, and when the current is 50~250A, the argon flow rate is 2~5L/min.

4. The length of the tungsten electrode protruding from the gas nozzle is preferably 4~5mm, 2~3mm in places with poor shielding such as corner welding, and 5~6mm in places with deep grooves. The distance from the nozzle to the workpiece generally does not exceed 5mm.

5. To prevent the appearance of welding pores, the welding parts must be cleaned if there is rust, oil, etc.

6. The arc length is preferably 2~4mm when welding ordinary steel, and ~3mm when welding stainless steel. If it is too long, the protection effect will be poor.

7. When butt-bonding, in order to prevent the back of the bottom weld from being oxidized, the back also needs to be protected by gas.

8. In order to make the argon gas protect the welding pool well and facilitate the welding operation, the center line of the tungsten electrode and the workpiece at the welding point should generally maintain an angle of 80~85°, and the angle between the filler wire and the workpiece surface should be as small as possible, generally around 0°.

9. Wind protection and ventilation. In windy places, please take measures to block the net, and take appropriate ventilation measures indoors.

Stainless Steel Material Comparison Table

|

Stainless Steel Type

|

Corrosion Resistance

|

Common Applications

|

Cost

|

|

304

|

High

|

Food Industry, Construction

|

Low

|

|

316

|

Very High

|

Marine, Chemical

|

Medium

|

|

Duplex

|

Very High

|

Oil, Gas

|

High

|

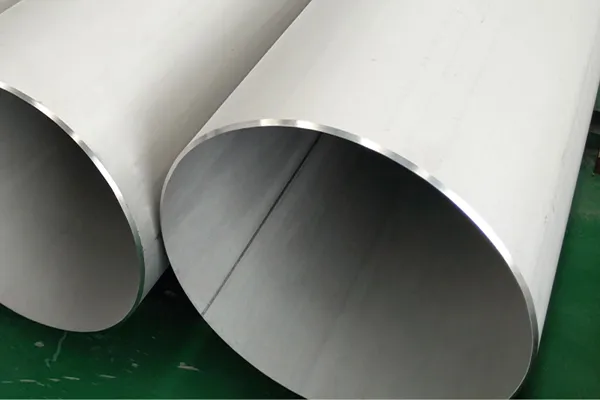

Advantages of stainless welded steel pipes

Stainless welded steel pipes-stainless steel strips with uniform wall thickness are welded and rolled once without adding solder under gas protection.

Advantages:

1. Uniform wall thickness - the parent material is a formed strip material with good wall thickness consistency and high surface finish, reaching industrial clean surface grade 2B.

2. Low residual stress - the formed steel pipe uses a high temperature higher than 1040 degrees to brightly anneal the stainless steel pipe to eliminate stress.

3. High weld strength - the welding adopts fusion welding, the material composition remains unchanged, and the weld has the same intergranular structure as the parent material after high temperature heat treatment. When the weld is subjected to destructive tests such as flattening, reverse bending, and flaring, there will be no cracking or cracks, burrs, etc. at the weld. In addition, eddy current testing and water pressure or gas test are required to ensure the quality of the pipe.

4. Good consistency - the outer diameter, wall thickness, length and straightness of the pipe are consistent and the processing accuracy is high.

Frequently Asked Questions (FAQ)

What are the benefits of 304 stainless steel pipes?

304 stainless steel is popular for its good corrosion resistance and durability in general applications, especially in the food and construction industries, and it is relatively inexpensive.

Can stainless steel welded pipes be used in marine environments?

Yes, but it is recommended to use 316 or duplex stainless steel, as these materials have higher molybdenum content and offer better resistance to corrosion in marine environments.

What should be considered when welding stainless steel pipes?

It is essential to use proper welding techniques (such as TIG or MIG welding) and regularly inspect the welding quality to avoid issues like porosity, defects, or weak welds.

Stainless steel pipes should be regularly inspected, cleaned with mild cleaners, and free of accumulated chemicals to ensure their long-lasting corrosion resistance and structural integrity.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :