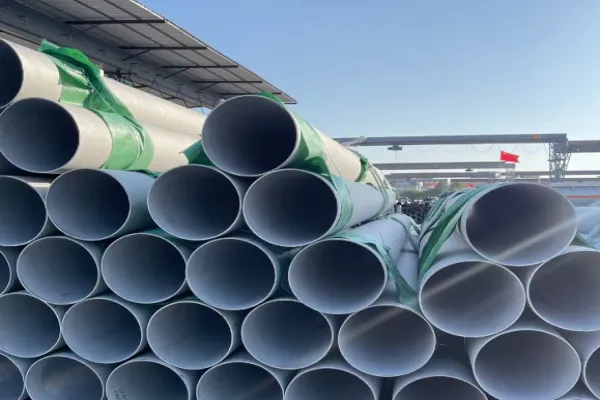

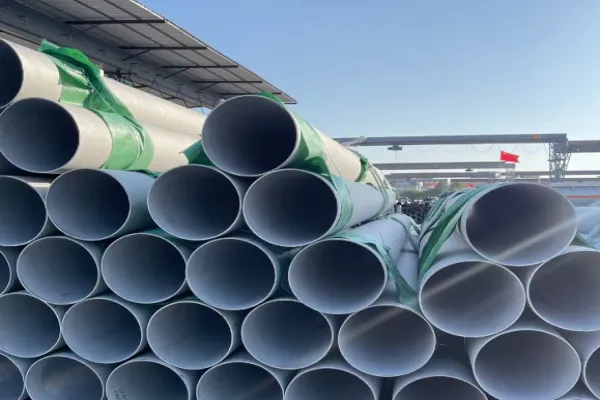

Stainless steel seamless pipe is a hollow cross-section pipe without welds manufactured by hot extrusion, cold drawing or cold rolling. It has unique structural advantages and material properties. Compared with welded steel pipes, seamless pipes eliminate the potential weak link of welds, making them more reliable and safer when subjected to high pressure, high temperature or corrosive media. The production process of this pipe has undergone a long period of technological evolution, from the initial ordinary seamless pipe to today's precision seamless pipe and ultra-thin wall seamless pipe. The product variety is increasingly rich and the application field is constantly expanding.

Stainless steel is a popular seamless pipe material because of its excellent corrosion resistance and ability to withstand high temperatures and high pressures. Seamless stainless steel pipes are used in a variety of industries, including oil and gas, chemical processing, power generation, food processing, etc. Stainless steel pipes are hollow, long round steels that are widely used in industrial pipelines such as petroleum, chemical, medical, food, light industry, mechanical instruments, and mechanical structural components. In addition, when the bending and torsional strengths are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, gun barrels, shells, etc.

1. Core applications in the petrochemical industry

As a pillar industry of the national economy, the petrochemical industry is one of the largest demand areas for stainless steel seamless pipes, accounting for more than 30% of the total consumption. In this field, stainless steel seamless pipes are widely used in various links of oil and gas exploration, oil refining and processing, chemical production and storage and transportation systems. Their excellent corrosion resistance, high temperature and high pressure resistance and reliable structural integrity have become key materials to ensure the safe and stable operation of petrochemical equipment. The special requirements of the petrochemical industry for stainless steel pipes have spawned a series of innovations in special materials and manufacturing technologies, driving the field to develop in the direction of higher parameters, longer life and greater safety and reliability.

2.Hygienic applications in food, medicine and medical devices

In the food processing and beverage industry, stainless steel seamless pipes are mainly used in key links such as liquid food delivery pipelines, storage tanks, heat exchange systems and filling equipment. 304 and 316 austenitic stainless steels are the most commonly used materials, with chromium content between 17%-19% and nickel content between 8%-10%. The passivation film formed can effectively prevent the precipitation of iron ions, avoid food contamination and maintain the original flavor. Dairy processing is a typical application scenario. The pipeline system needs to withstand high-temperature disinfection (above 120°C), acid and alkali cleaning, and erosion by organic matter such as cream and protein. 316L stainless steel seamless pipes have excellent local corrosion resistance due to their ultra-low carbon characteristics (C≤0.03%) and the addition of 2%-3% molybdenum elements, making them the standard for dairy factories. Juice and wine production equipment also rely on stainless steel seamless pipes, especially when processing acidic juices (such as orange juice pH≈3.5). The molybdenum-containing 316L material can effectively resist the erosion of organic acids, ensuring product quality and extending equipment life.

3.Construction and Municipal Engineering

Stainless steel seamless pipes are used as both structural materials and decorative elements. The load-bearing columns and space grids of high-rise buildings are made of 316 or 2205 duplex stainless steel seamless pipes, which have a yield strength nearly twice that of 304 stainless steel and can reduce the cross-sectional size. The claws of the curtain wall support system and point-supported glass curtain walls also rely on high-precision stainless steel seamless pipes, and the surfaces are mostly mirrored or textured to enhance the aesthetics. Municipal water supply systems gradually use 304 stainless steel seamless pipes to replace traditional materials. Tokyo, Japan has used them on a large scale in direct drinking water systems since 1980, significantly improving the water supply quality. The support system of the underground integrated pipeline corridor uses 316L or 2205 stainless steel seamless pipes, with a design life of up to 100 years, which greatly reduces maintenance requirements

4.Transportation and New Energy

The demand for seamless stainless steel pipes in the fields of transportation and new energy is growing rapidly. Automobile exhaust systems use seamless ferritic stainless steel (such as 409L, 436L) pipes to withstand 900°C high-temperature exhaust gas. The hydrogen storage system of hydrogen fuel cell vehicles uses 316L and super duplex stainless steel 2507 seamless pipes to resist hydrogen embrittlement in high-pressure hydrogen environments. The collector tubes of solar thermal power stations use heat-resistant alloy seamless pipes such as 310S and Incoloy 800H to withstand high-temperature molten salt corrosion. The hydraulic system and lubrication pipelines of wind power equipment are also gradually using 316L stainless steel seamless pipes to adapt to long-term use in harsh environments.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :