ASTM A500 is a standard issued by the American Society for Testing and Materials (ASTM) that covers the requirements for cold-formed welded and seamless carbon steel structural pipes. ASTM A500 is an important standard issued by the American Society for Testing and Materials

(ASTM) that specifies the chemical composition, mechanical properties, and inspection and packaging requirements of ASTM A500.

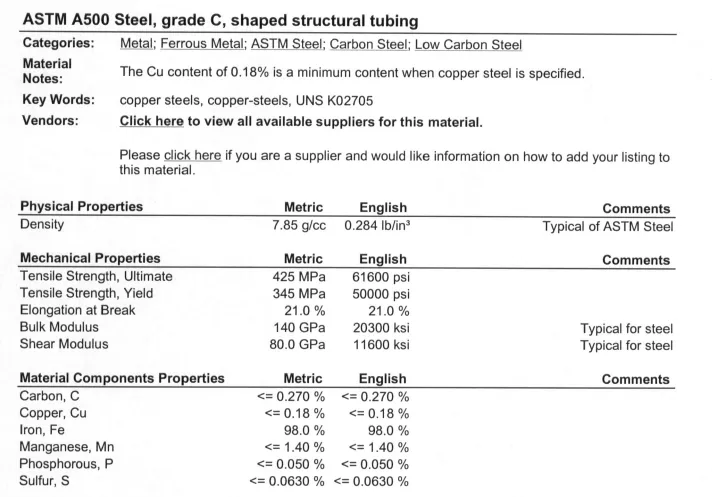

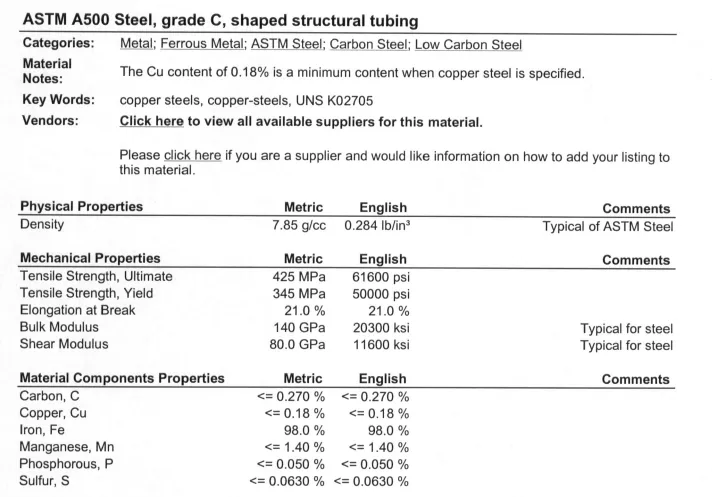

ASTM A500 Grade C is a widely used cold-formed seamless and welded carbon structural steel pipe. Among the three grades of ASTM A500, Grade C has the highest mechanical properties, with a minimum tensile strength of 425 MPa and a minimum yield strength of 345 MPa. It is mainly used in structural applications that require high strength and reliability.ASTM A500 Grade C steel is also often used in construction projects, where Grade B steel is also often used. Although both steel grades are widely available, Grade C steel is more affordable and therefore a more popular choice for many construction projects.

ASTM A500 Grade C Pipe Specification

Chemical Composition

If chemical analysis is used to measure the chemical elements of steel pipes, the methods and requirements should comply with the requirements of ASTM A751.

When purchasing ASTM A500 Grade C steel pipes, just check the chemical composition requirements in the product analysis section.

|

Composition, %

|

ASTM A500 Grade C

|

|

Heat Analysis

|

Product Analysis

|

|

Carbon, max

|

0.23

|

0.27

|

|

Manganese, max

|

1.35

|

1.40

|

|

Phosphorus, max

|

0.035

|

0.045

|

|

Sulfur, max

|

0.035

|

0.045

|

|

Copper, min

|

0.20

|

0.18

|

Mechanical Performance

The mechanical properties of ASTM A500 may be measured by tensile tests, the methods and definitions of which shall conform to the applicable requirements of ASTM A370, Appendix A2.

|

Tensile

|

ASTM A500 Grade C

|

|

Tensile strength, min

|

62000 psi [425 MPa]

|

|

Yield strength, min

|

50000 psi [345 MPa]

|

|

Elongation in 2 in. (50 mm), min

|

21%

|

Tensile Requirements of ASTM A500 Grade c Pipe

|

Round Structural Tubing

|

|

|

Grade C

|

|

Tensile strength, min, psi (MPa)

|

62,000 (425)

|

|

Yield strength, min, psi, (MPa)

|

46,000 (315)

|

|

Elongation in 2 in. (50 mm), min, %D

|

21C

|

|

Shaped Structural Tubing

|

|

|

Grade C

|

|

Tensile strength, min, psi (MPa)

|

62,000 (425)

|

|

Yield strength, min, psi, (MPa)

|

50,000 (345)

|

|

Elongation in 2 in. (50 mm), min, %D

|

21C

|

|

a. Applies to specified wall thicknesses (t) equal to or greater than 0.120 in. (3.05 mm). For lighter specified wall thicknesses, the minimum elongation values shall be calculated by the formula: percent elongation in 2 in. (50mm) = 56t + 17.5, rounded to the nearest percent. For A500M use the following formula: 2.2t + 17.5, rounded to the nearest percent.

b. Applies to specified wall thicknesses (t) equal to or greater than 0.180 in. (4.57 mm). For lighter specified wall thicknesses, the minimum elongation values shall be calculated by the formula: percent elongation in 2 in. (50 mm) = 61t + 12, rounded to the nearest percent. For A500M use the following formula: 2.4t + 12, rounded to the nearest percent.

c. Applies to specified wall thicknesses (t) equal to or greater than 0.120 in. (3.05 mm). For lighter specified wall thicknesses, the minimum elongation values shall be by agreement with the manufacturer.

d. The minimum elongation values specified apply only to tests performed prior to shipment of the tubing.

|

Uses and Applications of ASTM A500 Grade C Pipe

ASTM A500 Grade C structural pipe is used in various industries due to its excellent structural strength.

1. Construction and Metal Structures

It is used in the manufacture of structural frames, beams, and supports due to its high strength and ease of welding.

2. Infrastructure and Bridges

Due to its ability to withstand heavy loads, it is ideal for bridge and footbridge structures.

3. Automotive and Machinery

It is used in the manufacture of truck chassis, agricultural machinery, and industrial equipment.

4. Telecommunication Towers and Poles

Its weather resistance and ability to withstand vertical loads make it suitable for transmission towers and electrical poles.

FAQ

What is the difference between ASTM A500 and ASTM A53?

ASTM A500 is used in structural applications, whereas ASTM A53 is more common for pressure piping and fluid transport systems.

Is ASTM A500 Grade C corrosion-resistant?

Structural steel is not inherently corrosion-resistant and may require protective coatings in humid or corrosive environments.

How is ASTM A500 Grade C pipe manufactured?

It is produced using the electric resistance welding (

ERW) process and cold-formed to ensure the required structural strength.

What shapes are available for ASTM A500 tubing?

ASTM A500 pipes are available in round, square, and rectangular shapes, depending on structural project requirements.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :