Characteristics and Functions of Well Pipe Casing

Well pipe casing is essential in oil and gas drilling. Its primary role is to maintain the structural integrity of the wellbore. This article explores its characteristics and functions, emphasizing its importance in drilling operations.

OCTG Tubing pipe is a type of pipe used in the oil and gas industry, specifically within wells, to transport fluids (such as oil, gas, or water) from the production zone to the surface. Tubing is the simplest part of OCTG and it is normally found in the segment of 30 ft (9 m), with threaded connections at both ends. The pipe is either used to transport natural gas or crude oil from the producing formation to the facilities where it will be processed after drilling is complete. Here are some key characteristics and functions of tubing pipe:

1. Fluid Transport: Tubing serves as the conduit for the extracted fluids, allowing them to flow from the reservoir to the surface facilities for processing and storage.

2. Smaller Diameter: Tubing pipes typically have a smaller diameter compared to casing pipes, which allows for efficient flow rates and easier handling during installation.

3. Pressure Resistance: Tubing is designed to withstand the pressures encountered during production, ensuring safe and reliable transport of fluids.

4. Installation: Tubing is installed inside the casing and can be easily removed or replaced if necessary, facilitating maintenance and repairs.

5. Production Optimization: The design and material of tubing can be optimized for specific production conditions, enhancing the efficiency of fluid extraction.

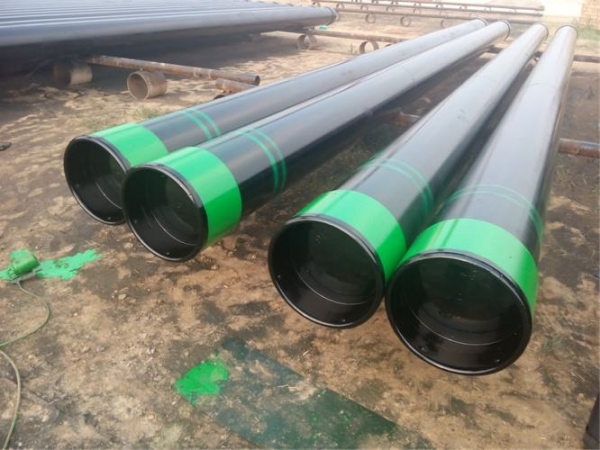

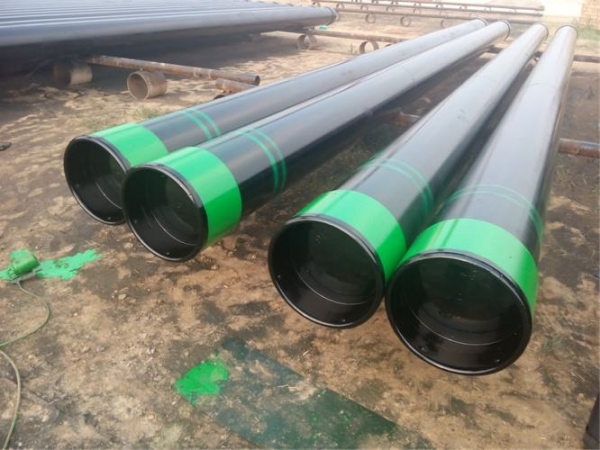

Primary Functions of Well Pipe Casing

Maintaining Wellbore Stability

One of the primary functions of well pipe casing is to stabilize the wellbore. It prevents surrounding rock and soil from caving in, which can compromise the drilling process.

Isolating Different Geological Zones

Well pipe casing isolates various geological formations encountered during drilling. This function prevents the mixing of fluids between zones, preserving reservoir integrity.

Protecting Freshwater Aquifers

By isolating the wellbore from surrounding aquifers, casing protects freshwater sources from contamination. This function is particularly vital for environmental safety.

Facilitating Pressure Management

The casing assists in managing pressures during drilling and production. It provides a controlled pathway for fluid movement, enhancing safety and operational control.

Supporting Downhole Equipment

The casing serves as a support structure for downhole equipment like tubing and production tools. This ensures efficient extraction and flow of hydrocarbons to the surface.

Importance of Well Pipe Casing in Drilling Operations

The role of well pipe casing in ensuring operational safety cannot be overstated. It minimizes environmental risks, enhances drilling efficiency, and prevents costly downtime. Additionally, its ability to adapt to different conditions makes it indispensable in oil and gas extraction.

OCTG Tubing pipe standard

Same as casing pipe standard, OCTG tubing in API 5CT is also in the same material grades (J55/K55, N80, L80, P110 etc), but the tubing’s diameters are up to 4 1/2”, and it ends in various types such as BTC, EUE, NUE, and premium. Most commonly, thickened connections EUE.

OCTG Casing Pipe standard

Steel Casing pipe standards usually referred to API 5CT, Common Grades in J55/K55, N80, L80, C90, T95, P110 etc. Common length in R3 which nominal at 40 ft / 12 meters. Casing pipe ends connection types are usually in BTC and LTC, STC. And premium connections are also required in large quantities in an oil and gas piping project.

Steel Well Casing Pipe Price

Steel Casing Pipe cost is lower than drill pipe or the OCTG tubing cost, it is usually higher 200 USD than the regular API 5L pipe. Considering the Threading + Coupling cost or the heating treatment.

Features for OCTG pipe

All OCTG pipes have a standard requirement of dependable hardness. So, whether it is OCTG tubing, OCTG pipe or OCTG drill pipe, there is a certain required standard that is always about super hardness. To meet the standard, manganese and chromium are used as the main alloys to confirm cohesion and durability.

There has been recent developments to eliminate sulfide stress cracking, which is the major problem with manganese and chromium. Alloy and Molybdenum are blended together to overcome the chromium and manganese limitations. So OCTG pipes are now harder than ever, and the fear of sulfide stress cracking has been eliminated.

Conclusion

In conclusion, well pipe casing is vital in drilling operations due to its unique characteristics and essential functions. From maintaining stability to isolating geological zones, its role supports safe and efficient extraction. Understanding these aspects helps optimize its application, ensuring successful and sustainable drilling outcomes.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :