What is Oil Country Tubular Goods(OCTG)?

OCTG is the abbreviation of Oil Country Tubular Goods, which mainly refers to the pipe products used in oil and gas production (drilling operations). Oil Country Tubular Goods are usually manufactured according to API specifications or related standard specifications. Thick-walled oil country tubular goods manufacturers must not only meet the specifications of each customer, but also meet the requirements of

API 5L & 5CT, ISO, EN and other standards. It can also be considered as a general term for drill pipes, steel casings, fittings, joints and accessories used in the onshore and offshore oil and gas industry. These products can be either welded or seamless. In order to control the chemical properties and apply different heat treatments, oil country tubular goods are divided into more than ten grades of different performance materials. OCTG also usually includes a series of accessories (commonly called pipes) and various accessories involved in its manufacturing and processing. These accessories include drill pipes, casings or tubing, thread protectors, insertion guides, buffer rings and pipe plugs.

Types of Oil Country Tubular Goods (OCTG Pipe)

There are four main types of oil country tubular goods, including drill pipes, casings and tubing, short joints.

Drill pipe

Drill pipe refers to heavy, usually seamless, pipes that are used to rotate the drill bit and drilling fluid, and can be joined together using tool joints. Drill pipe is subject to axial tension (due to its own deadweight when in use), high internal pressure (due to the expulsion of drilling fluid), and extremely high torque (due to the actual drilling and turning of the drill bit). In other words, drill pipe is heavy, very strong pipe that is vital in any oil well pipe work.

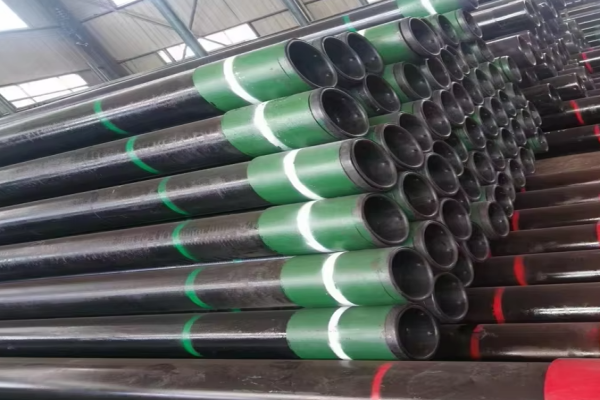

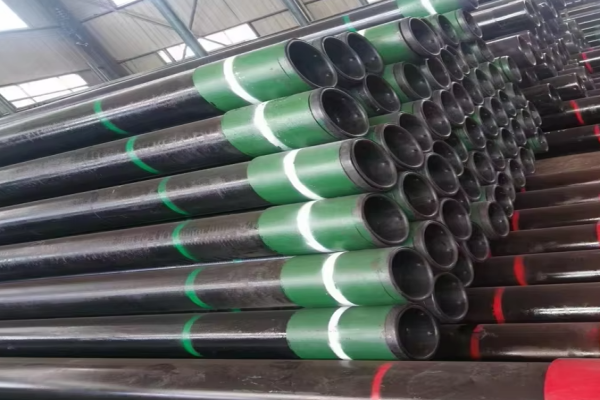

Casing pipe

Casings cover the inside of the wellbore and shape the wellbore. They prevent the well from collapsing and protect the wellbore from external pressure. They also make it easier to extract oil and gas from the well. There are a variety of casings on the market, each with different sizes and qualities.

Oil tubing pipe

Oil tubing pipe is the pipe inside the casing. The oil will eventually flow out of this pipe. Oil tubing pipe is the simplest of the OCTG series and is usually available in sections of about 9 meters (30 feet) with threaded connections at both ends, and can be protected with drill pipe protectors during transportation and storage. These protectors also help prevent any corrosion that may occur during storage, which can cause major problems when large quantities of oil are being pumped.

Pup joint

A pup joint is a piece of casing, pipe, or tubing that is shorter than a standard string. When a specific project requires that pipe be placed downhole, a pup can be used to adjust and install tools and various tubular components. Spacer pipe is another reference used to identify a pup joint. Characteristics of a pup joint include connection, length, weight, and material grade.

OCTG Tubing Standards

Similar to casing pipe standards, OCTG tubing under API 5CT has material steel grades (J55/K55, N80, L80, P110, etc.), diameters up to 4 1/2", and a variety of end types such as thickened thread, non-thickened thread, long round thread, short round thread, and trapezoidal thread.

Importance of Oil Well Tubular Goods in Industry

The oil and gas industry is completely dependent on oil well tubular goods. Casing is essential to maintain the structural integrity of the well, prevent the well from collapsing due to the pressure exerted by the surrounding rocks, and prevent fluid migration between formations.

Tubing is the pipe that carries oil or gas from the reservoir to the surface, ensuring efficient production. Tubing is also the conduit for chemical injection, gas lift, and other downhole processes.

Drill pipes are essential for drilling as they transmit torque and drilling fluid to the drill bit. To effectively penetrate various rock formations, they must withstand tremendous stress and torsional forces.

The main characteristics of OCTGs are reliability and durability. Failure of these tubular products can lead to serious consequences such as blowouts, environmental damage, and production losses. To ensure the integrity and safety of OCTGs, we implement strict quality control measures such as material selection, manufacturing processes, and testing.

Baowi-Steel: Your Trusted OCTG Manufacturer and Supplier

Baowi-Steel specializes in manufacturing high-quality OCTG (Oil Country Tubular Goods) products designed to meet the stringent requirements of the oil and gas industry. Our product range includes

seamless steel pipes, drill pipes,

casings and tubing, all of which are precision-processed and subject to stringent quality control. With advanced production facilities and strict quality standards, every product of

Baowi-Steel not only meets industry standards, but also exceeds your expectations. Choose us to provide reliable and durable OCTG solutions for your drilling operations, improving operational efficiency and success rate.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :